Low-temperature phase-change thermochromic film and preparation method thereof

A technology of thermochromic and low-temperature phase change, applied in the direction of coating, etc., can solve the problems of low stability and durability, insensitivity to temperature, and high phase transition temperature of thermochromic film, so as to reduce the phase transition temperature, The effect of high optical sensitivity and high absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

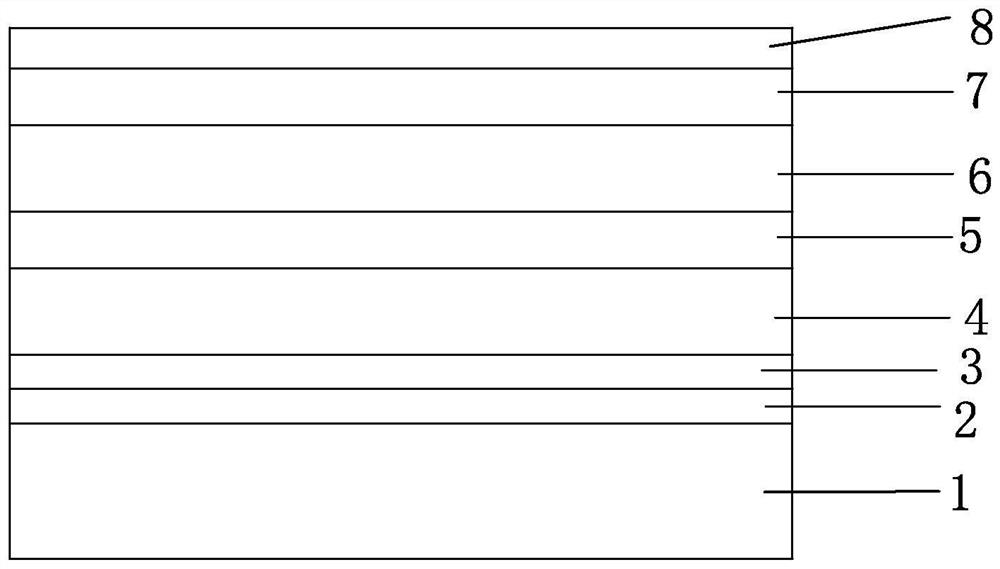

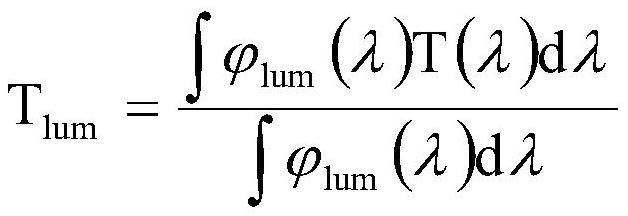

Method used

Image

Examples

Embodiment 1

[0035] Preparation method of low temperature phase change temperature discoloration film, comprising the following steps:

[0036] Step 1: After cleaning the high-quality float glass substrate with deionized water, plasma bombardment is carried out for 2min through Ar and Rf with a gas flow rate of 100sccm, and the power is 600W;

[0037] Step 2: The optical absorbent 2D conjugated dithiophene benzophene p-fluorobenzotriazole copolymer is sprayed on the glass substrate after plasma bombardment to obtain the substrate;

[0038] Step 3: Take Ar gas and O on the substrate in step 2 2 Gas as sputtering gas, silicon aluminum as the target, gas flow rate of 100:120sccm, using magnetron sputtering method to prepare the bottom layer, film thickness of 30nm;

[0039] Step 4: Hit the bottom layer in step 3 with Ar gas and O 2 Gas as sputtering gas, with high refractive index material as the target material, gas flow rate of 100:120sccm, using magnetron sputtering method to prepare the mediu...

Embodiment 2

[0046] Preparation method of low temperature phase change temperature discoloration film, comprising the following steps:

[0047] Step 1: After cleaning the high-quality float glass substrate with deionized water, plasma bombardment is carried out for 2min through Ar and Rf with a gas flow rate of 110sccm, and the power is 700W;

[0048] Step 2: The optical absorbent 2D conjugated dithiophene benzophene p-fluorobenzotriazole copolymer is sprayed on the glass substrate after plasma bombardment to obtain the substrate;

[0049] Step 3: Take Ar gas and O on the substrate in step 2 2 Gas as sputtering gas, silicon aluminum as the target, gas flow rate of 100:120sccm, using magnetron sputtering method to prepare the bottom layer, film thickness of 40nm;

[0050] Step 4: Hit the bottom layer in step 3 with Ar gas and O 2 Gas as sputtering gas, with high refractive index material as the target material, gas flow rate of 100:120sccm, using magnetron sputtering method to prepare the mediu...

Embodiment 3

[0057] Preparation method of low temperature phase change temperature discoloration film, comprising the following steps:

[0058] Step 1: After cleaning the high-quality float glass substrate with deionized water, plasma bombardment is carried out for 2min through Ar and Rf with a gas flow rate of 120sccm, with a power of 800W;

[0059] Step 2: The optical absorbent fullerene receptor is sprayed on the glass substrate after plasma bombardment to prepare the substrate;

[0060] Step 3: Take Ar gas and O on the substrate in step 2 2 Gas as sputtering gas, silicon aluminum as the target, gas flow rate of 100:120sccm, using magnetron sputtering method to prepare the bottom layer, film thickness of 35nm;

[0061] Step 4: Hit the bottom layer in step 3 with Ar gas and O 2 Gas as sputtering gas, with high refractive index material as the target material, gas flow rate of 100:120sccm, the use of magnetron sputtering method to prepare the medium film layer, film thickness of 35nm;

[0062]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com