Azithromycin amine crystallization method

A technology of azithromycin amine and crystallization, applied in the field of crystallization of azithromycin amine, can solve the problems of difficult preservation, dangerous production process, fast degradation speed of azithromycin amine, etc., achieves simple operation and process control, reduces the influence of product quality, and reduces solvent The effect of the recycling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

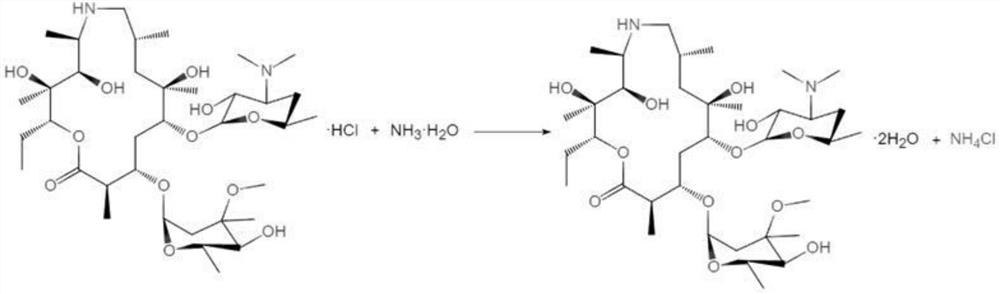

[0022] The following technical solution is described in detail in conjunction with an embodiment of the present invention, the present invention discloses a crystallization method of azithromycin. The preparation of azithromycin acid aqueous phase is carried out first, and then the aqueous phase of azithromycin is reacted with azithromycin, and the solid-liquid separation is carried out by taking advantage of the water-insoluble nature of the generated azithromycin. Its reaction formula is as follows:

[0023]

[0024] The crystallization steps are described below:

[0025]Add 2300L of drinking water to the chloroform phase of azithromycin, cool down to 0~ 10 °C; add 32% hydrochloric acid dropwise to adjust the pH of 4.5 to 5, stir for 10 to 20 min and then stand for 20 to 30 min, split into phases, separate out of the aqueous phase of azithromycin acid; add 3000L of water to the crystallization tank, heat up to 55 °C. Since azithromycin is unstable in acidic or alkaline cases, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com