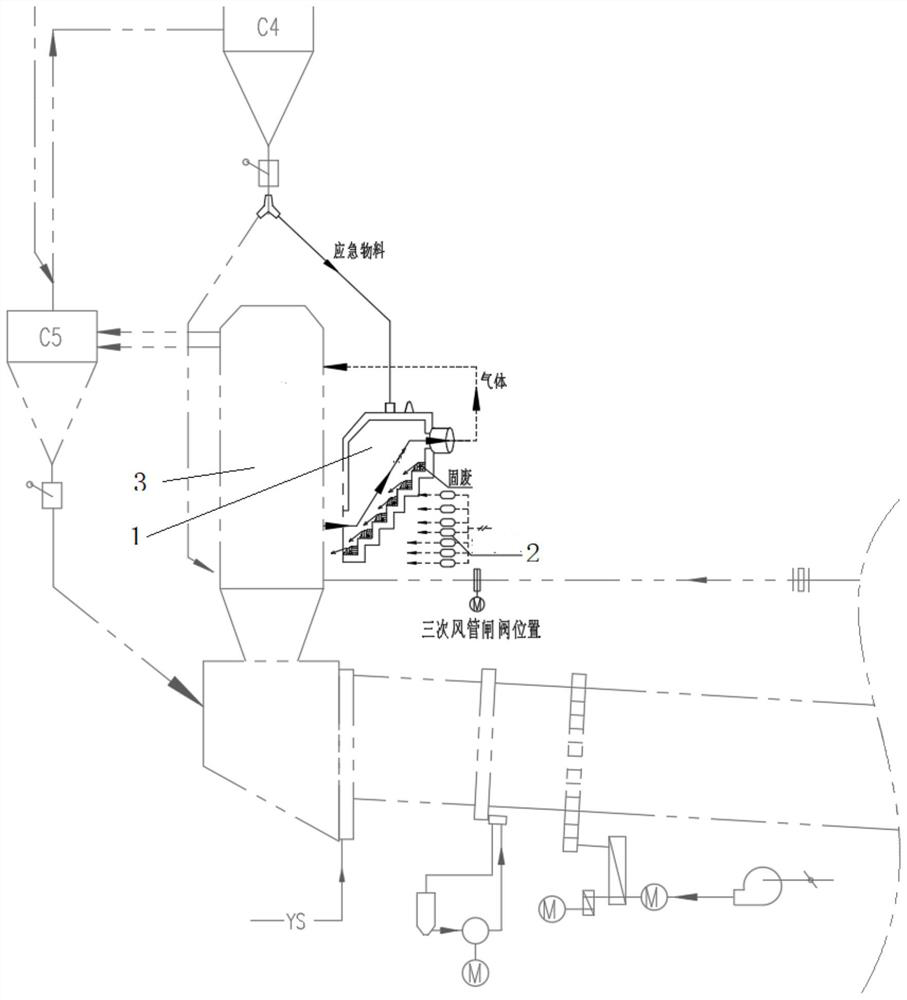

Novel countercurrent stepped solid waste pre-calcining device for dry-process clinker line decomposing furnace

A stepped and pre-calcining technology, applied in furnaces, incinerators, combustion types, etc., can solve problems such as high-temperature skinning in the firing system, system fluctuations, and affecting system operation, so as to improve the quality of clinker, reduce the impact, The effect of prolonged residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

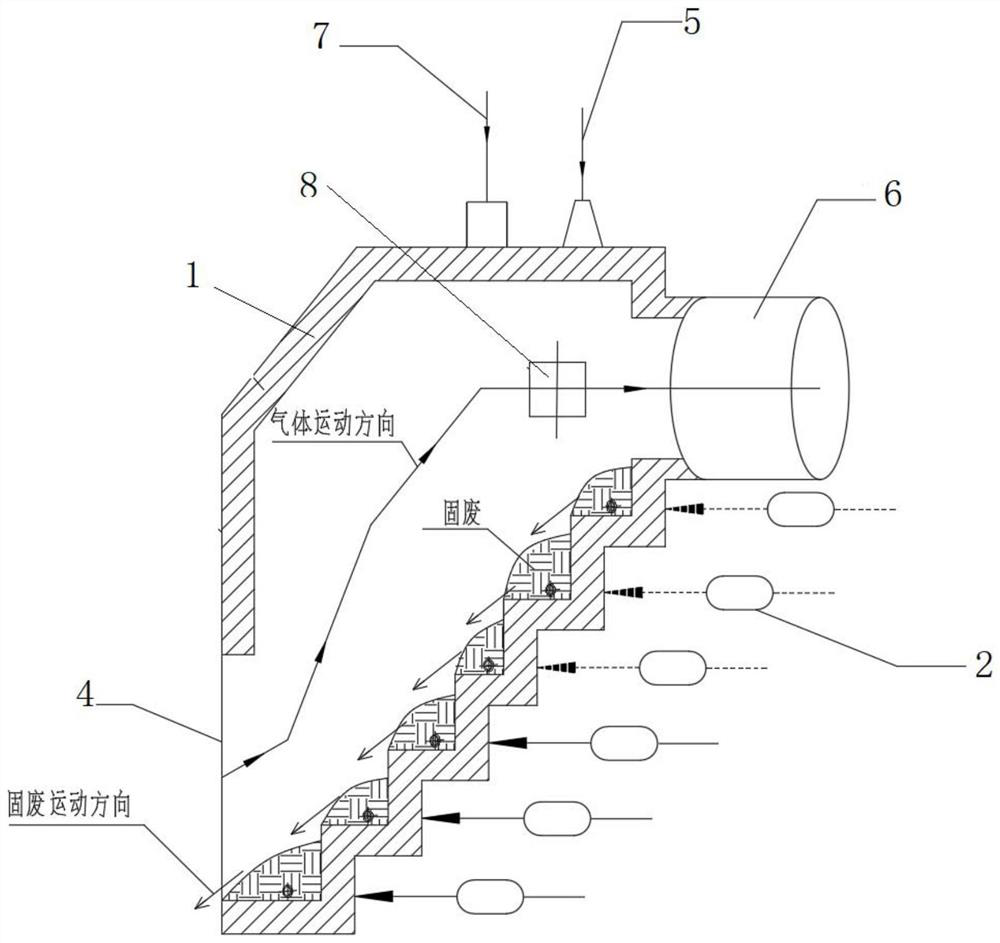

[0024] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0025] The invention provides a new type of countercurrent stepped solid waste pre-calcination device for a new type of dry process clinker line decomposition furnace. The countercurrent stepped solid waste precalcination device includes a countercurrent stepped calciner 1 and an air cannon 2. The lower right part is set in a ladder shape, and the counterflow stepped calciner 1 is equipped with an air cannon 2 at each step on the outside. The air cannon 2 is used to blow the solid waste and turn it from the upper step to the next step. The counterflow step The lower left part of the calciner 1 is provided with a ventilation port 4 communicating with the calciner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com