Feed transfer system

A feed and circulation tube technology, applied in animal feeding devices, poultry industry, food processing, etc., can solve problems such as being unfavorable to the health of the animals being farmed, easy to stick to the conveying equipment, and easy to affect the health of breeding, etc. Fluency, avoid caking or mold, ensure the effect of smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

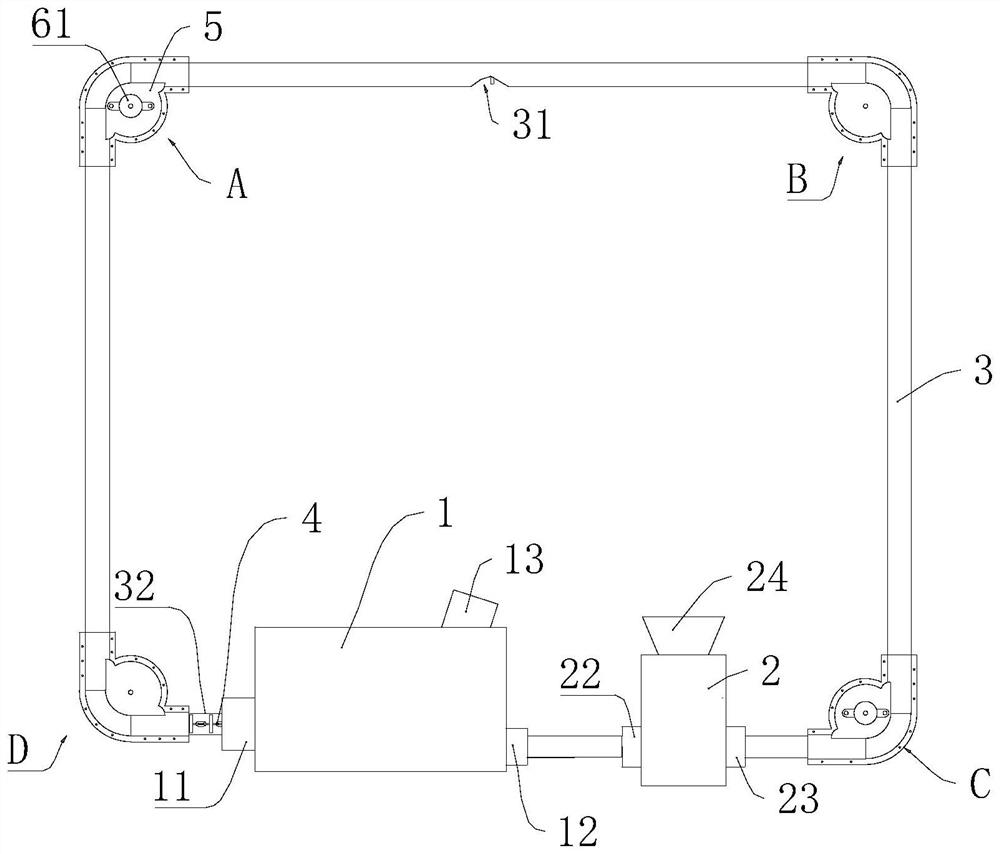

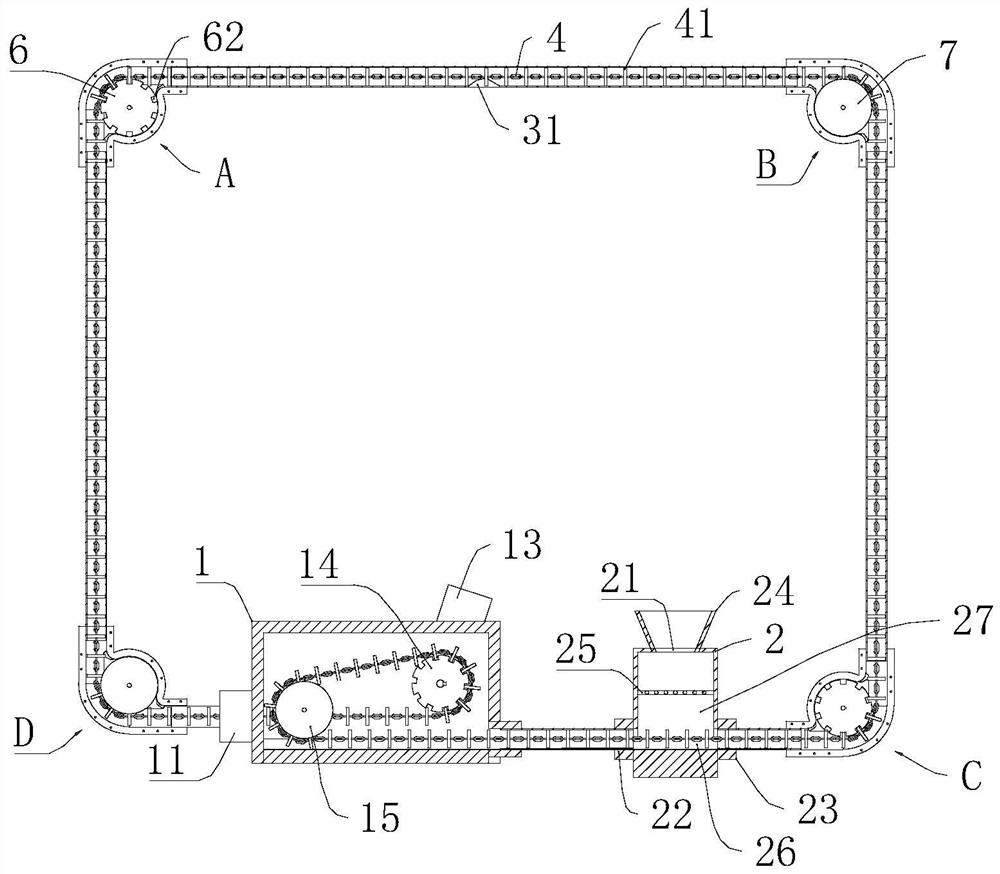

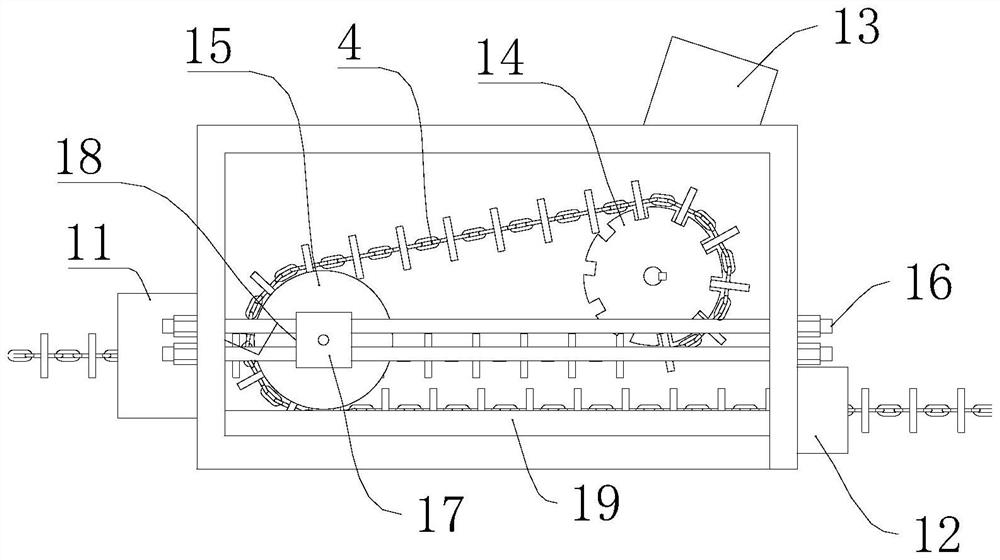

[0049] as Figure 1 As shown, the feed circulation transfer system, comprising a drive box 1, a material box 2, a flow line 3 and a circulating rigging 4, a drive box 1 comprises a drive box inlet 11 and a drive box outlet 12. Bin 2 includes a sizing port 21, a bin inlet 22 and a bin outlet 23. The flow line 3 includes a plurality of corner devices 5, each corner device 5 is located at the corner of the flow line 3, a corner device is provided at A, B, C and D, and four corner devices are provided. The flow pipe is routed by the detachable splicing of the multi-segment pipe and the corner device.

[0050] as Figure 1 、 Figure 2 and Figure 6As shown, the flow line 3, the bin 2 and the drive box 1 are connected in series on the closed-loop path of the circulating rigging 4. One end of the flow line 3 is connected to the drive box inlet 11, the other end of the flow line 3 is connected to the container outlet 23, the container inlet 22 and the drive box outlet 12. The loop rigging 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com