M-SiO2 (at) EDTMPA composite material and preparation method and application thereof

A composite material, m-sio2 technology, applied in the field of material processing, can solve the problems that it cannot be used directly as a flame retardant, strong ethylenediamine tetramethylene phosphonic acid, etc., and achieve the goal of avoiding adverse effects and good flame retardant performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

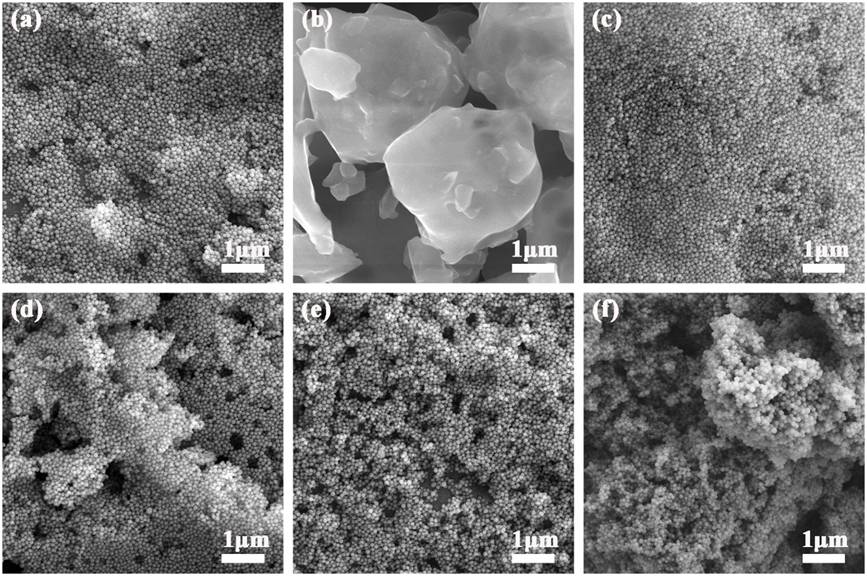

Image

Examples

Embodiment 1

[0020] Weigh 0.5 g of ethylenediaminetetramethylenephosphonic acid (EDTMPA), mesoporous silica (m-SiO 2 ) 1 g, mixed uniformly and heated until EDTMPA melted, kept for 3 min, and the nanocomposite flame retardant m-SiO can be obtained after cooling 2 @EDTMPA, marked as SiP1.

Embodiment 2

[0022] Weigh 1 g of ethylenediaminetetramethylenephosphonic acid (EDTMPA), mesoporous silica (m-SiO 2 ) 1 g, mixed uniformly and heated until EDTMPA melted, kept for 5 min, and the nanocomposite flame retardant m-SiO can be obtained after cooling 2 @EDTMPA, marked as SiP2.

Embodiment 3

[0024] Weigh 2 g of ethylenediaminetetramethylenephosphonic acid (EDTMPA), mesoporous silica (m-SiO 2 ) 1 g, mixed uniformly and heated until EDTMPA melted, kept for 15 min, and then cooled to obtain nanocomposite flame retardant m-SiO 2 @EDTMPA, marked as SiP3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com