Preparation method of ferrite-based magnetic antenna substrate

A magnetic antenna and ferrite technology, which is applied in the field of preparation of ferrite-based magnetic antenna substrates, can solve the problems of gain influence and low antenna efficiency, and achieve the effect of reducing magnetic and dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

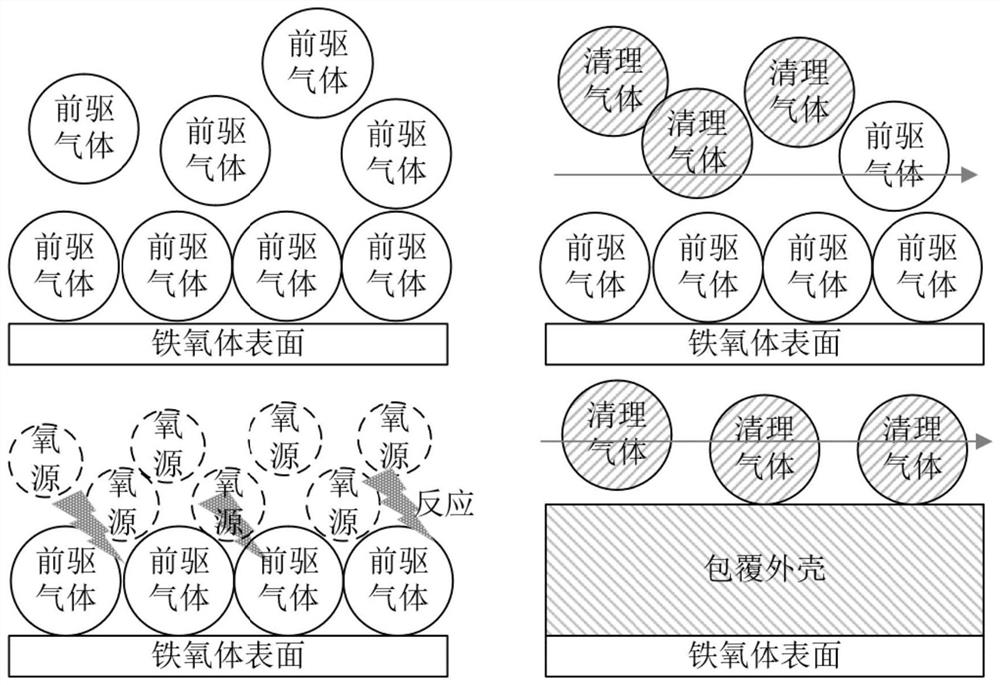

[0030] A method for preparing a ferrite-based magnetic antenna substrate of the present invention is specifically implemented according to the following steps:

[0031] Step 1, ALD treatment is carried out on the ferrite raw material, specifically:

[0032] Step 1.1, put the ferrite raw material into the atomic deposition equipment, evacuate until the chamber pressure is less than 5.3Pa, and at the same time raise the temperature to the preset temperature and keep it warm for 30min;

[0033] The preset temperature is 50-200°C;

[0034] The ferrite raw material is any one of M-type hexagonal ferrite, Y-type hexagonal ferrite, Z-type hexagonal ferrite, and spinel-type ferrite;

[0035] The general formula of M-type hexagonal ferrite is Ba(CoTi) x Fe 12-2x o 19 , 0

[0036] The general formula of Y-type hexagonal ferrite is Ba 2 co 2 Fe 12 o 12 ;

[0037] The general formula of Z-type hexagonal ferrite is Ba 3 co 2 Fe 24 o 41 ;

[0038] The general formula of ...

Embodiment 1

[0056] A method for preparing a ferrite-based magnetic antenna substrate of the present invention is specifically implemented according to the following steps:

[0057] Step 1, ALD treatment is carried out on the ferrite raw material, specifically:

[0058] Step 1.1, put the ferrite raw material into the atomic deposition equipment, evacuate until the chamber pressure is less than 5.3Pa, and at the same time raise the temperature to the preset temperature and keep it warm for 30min;

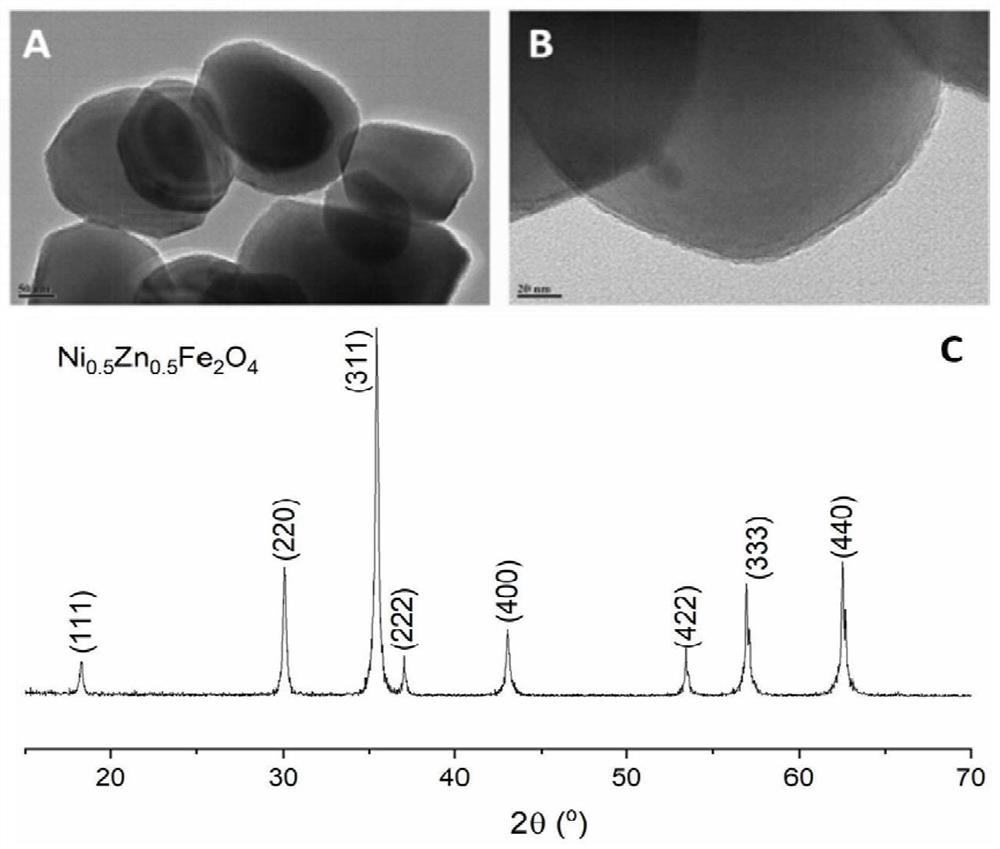

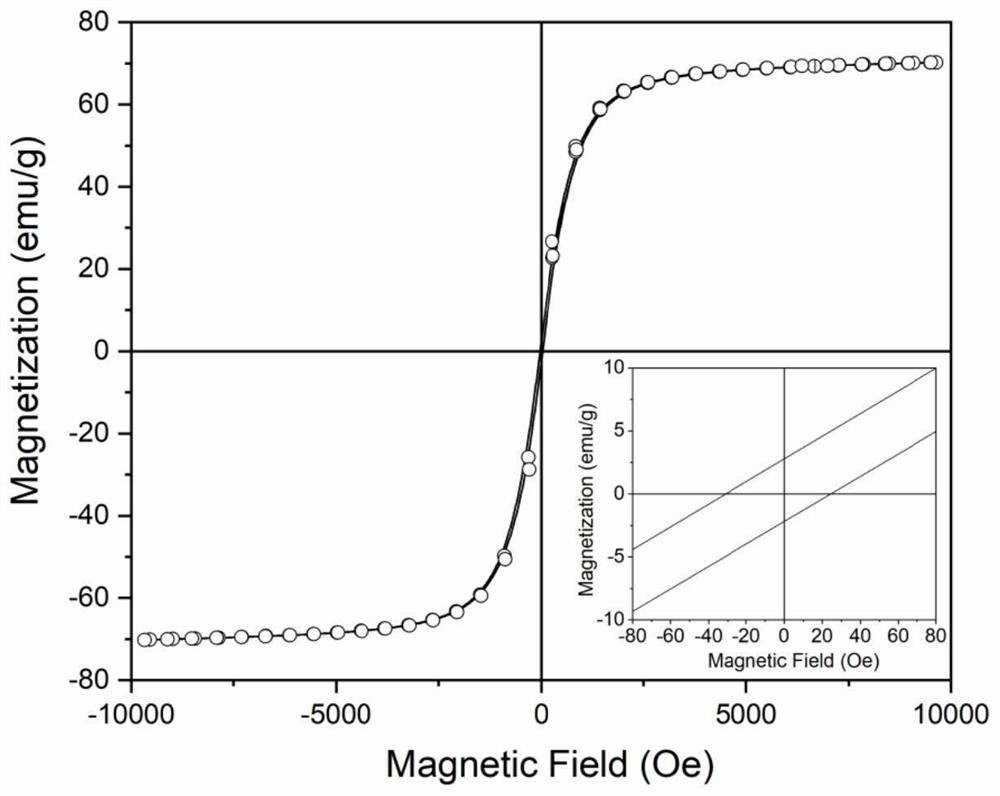

[0059] The preset temperature is 150°C; the raw material of ferrite is spinel ferrite; the general formula of spinel ferrite is Ni x Zn y co z Cu 1-x-y-z Fe 2 o 4 , 00.5 Zn 0.5 Fe 2 o 4 (Abbreviated as: NZO);

[0060] In step 1.2, the precursor material is heated and vaporized to form a precursor gas, and the precursor gas and the oxygen source gas are respectively passed into the atomic deposition equipment for atomic deposition reaction;

[0061] The precursor is trimethylaluminum Al(...

Embodiment 2

[0068] A method for preparing a ferrite-based magnetic antenna substrate of the present invention is specifically implemented according to the following steps:

[0069] Step 1, ALD treatment is carried out on the ferrite raw material, specifically:

[0070] Step 1.1, put the ferrite raw material into the atomic deposition equipment, evacuate until the chamber pressure is less than 5.3Pa, and at the same time raise the temperature to the preset temperature and keep it warm for 30min;

[0071] The preset temperature is 170°C;

[0072] The ferrite raw material is Z-type hexagonal ferrite; the general formula of Z-type hexagonal ferrite is Ba 3 co 2 Fe 24 o 41 ;

[0073] In step 1.2, the precursor material is heated and vaporized to form a precursor gas, and the precursor gas and the oxygen source gas are respectively passed into the atomic deposition equipment for atomic deposition reaction;

[0074] The precursor is tetrakis(dimethylamino)titanium C 8 h 24 N 4 Ti; the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Circular diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com