Device and process for preparing natural gas through closed-loop circulation comprehensive utilization of synthesis ammonia tower rear gas

An ammonia synthesis tower and natural gas technology, applied in the field of synthetic ammonia, can solve problems such as affecting the synthesis rate and inability to remove, and achieve the effects of optimizing the process flow, restoring the effective volume ratio, and eliminating internal friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

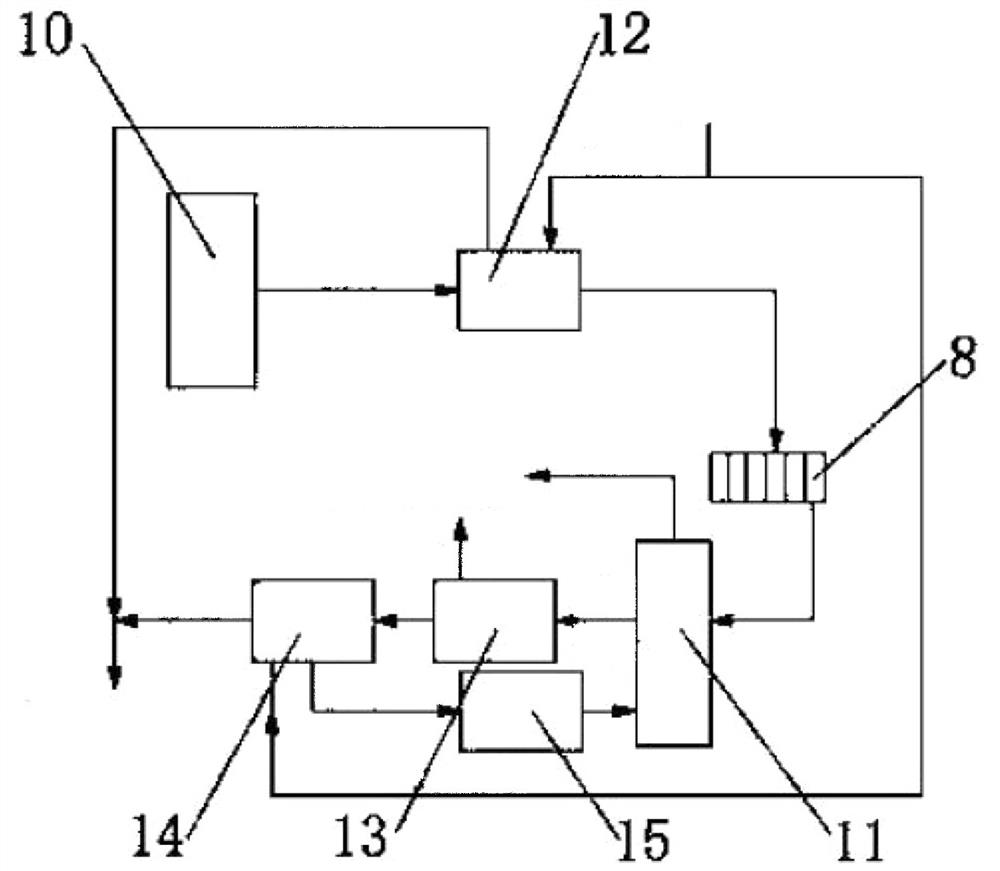

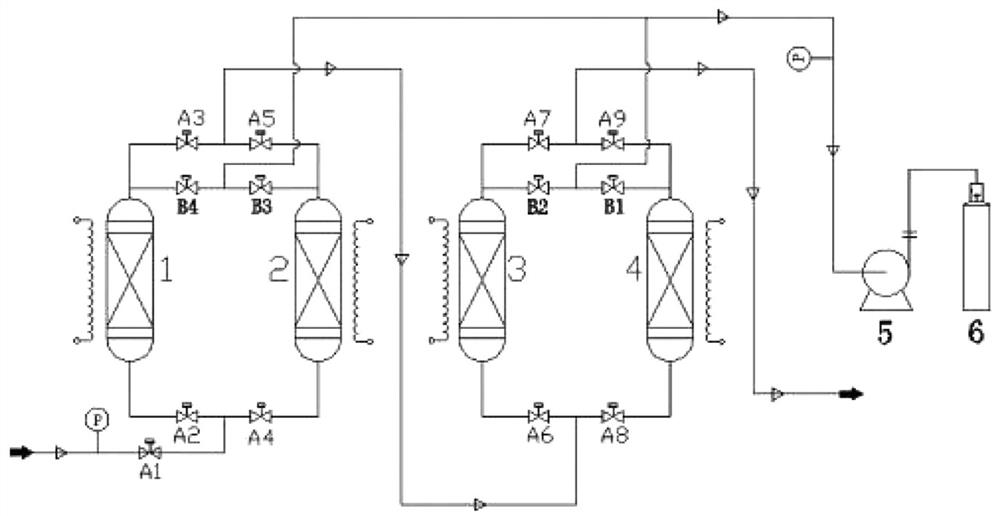

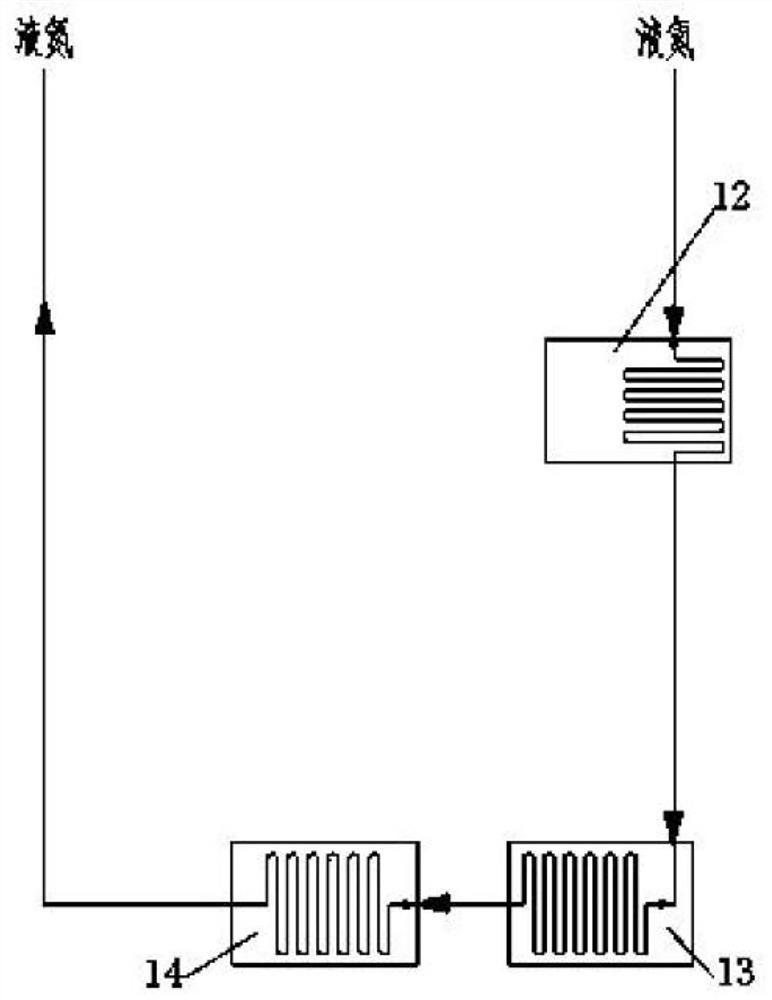

[0042] like figure 1 As shown in the figure, a process for preparing natural gas by comprehensive utilization of closed-loop gas after the ammonia synthesis tower adopts a synthetic ammonia system 11, a low-pressure methane synthesis system 10, a low-pressure cold box 12, a first high-pressure cold box 13, a second high-pressure cold box 14, and six sections. The fully closed cycle operation system formed by the connection of the high-pressure machines 8 is used to prepare natural gas; the low-pressure cold box 12 is respectively connected to the low-pressure methane synthesis system 10 and the fourth-stage inlet of the six-stage high-pressure machine 8, and the fourth-stage inlet of the six-stage high-pressure machine 8 is connected to the nitrogen pipeline, and the six-stage high-pressure machine 8 is connected to the nitrogen pipeline. The six-stage outlet of the stage high-pressure machine 8 is connected to the synthetic ammonia system 11, the synthetic ammonia system 11 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com