Cross cutting PDC (Polycrystalline Diamond Compact) drill bit and design method

A drill bit and cutting tooth technology, which is applied in the field of cross-cut PDC drill bit and design, can solve the problems of wear speed difference, reduce the overall performance of the drill bit, and poor wear balance of cutting teeth, so as to ensure cleaning and cooling conditions, improve wear balance and Ingestion ability and effect of reducing wear rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

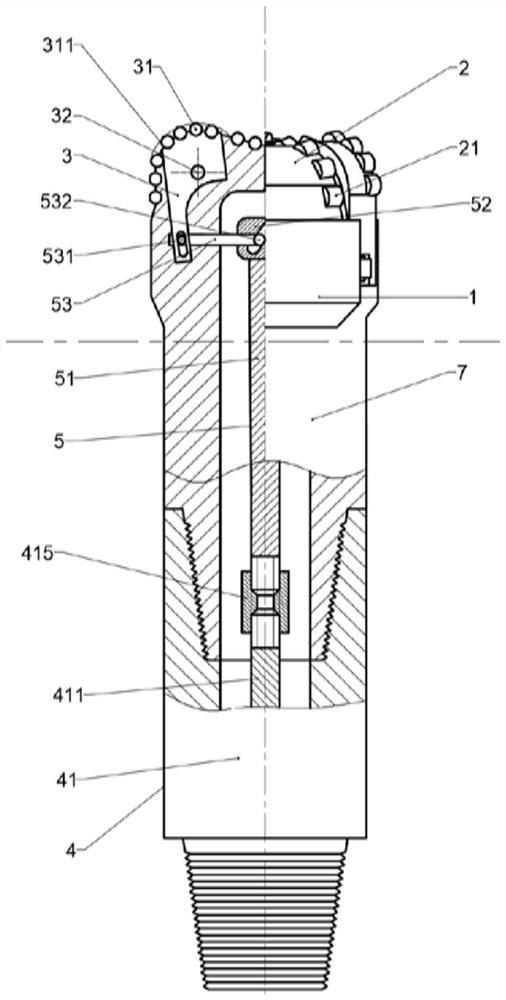

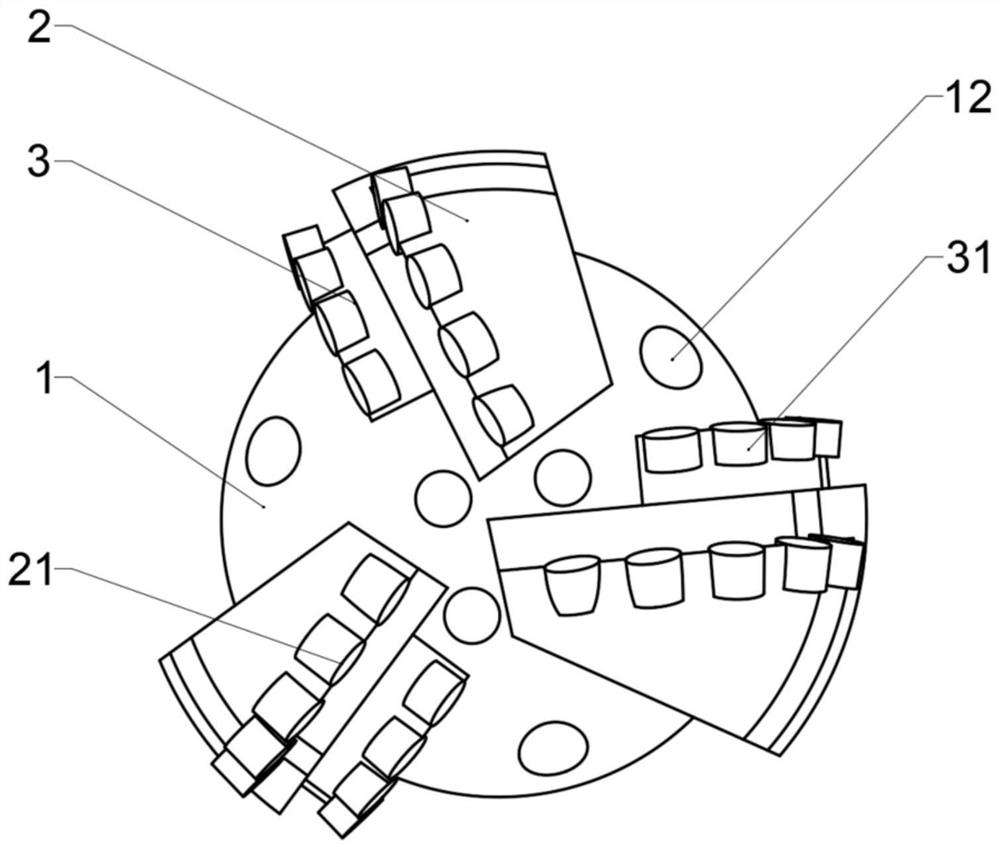

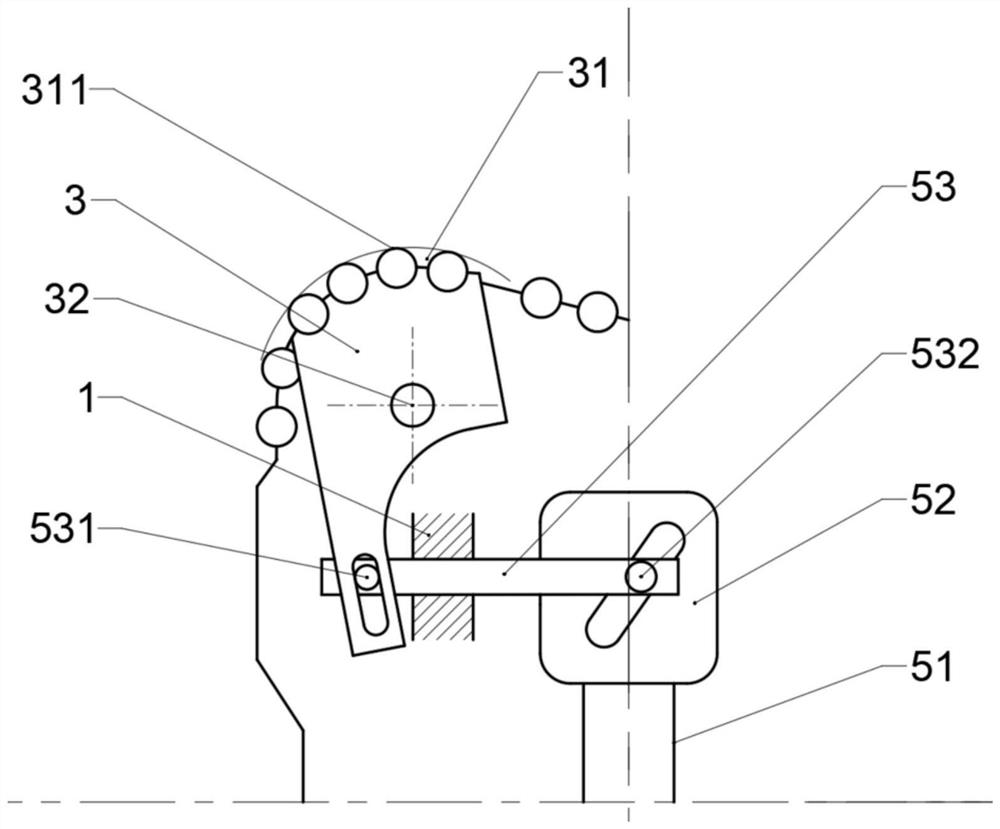

[0073] like Figure 1 to Figure 7 As shown, a cross-cutting PDC drill bit and design method include a drill bit body 1, a water hole 12 and a fixed cutting structure 2 fixed on the drill bit body 1, and a first group of cutting teeth 21 are arranged on the fixed cutting structure. The drill bit also includes a movable cutting structure 3 with a second row of cutting teeth 31, an axial push-pull short section 4 provided with an axial reciprocating motion generator 41, and a transmission mechanism 5. The transmission mechanism 5 adopts a cam mechanism, including an input shaft 51, Cam 52 and push rod 53.

[0074] The first set of cutting teeth 21 and the second set of cutting teeth 31 arranged on the cutting structure of the drill bit are polycrystalline diamond compacts, and can also be thermally stable polycrystalline diamond, natural diamond and impregnated diamond.

[0075] The drill bit body 1 adopts a split structure and is formed by connecting an axial push-pull short se...

Embodiment 2

[0087] This embodiment is basically the same as Embodiment 1, except that the movable cutting structure 3 is arranged on the rear side of the fixed cutting structure 2, such as Figure 14 shown.

Embodiment 3

[0089] This embodiment is basically the same as the embodiment 1, and the difference lies in that: the movable cutting structure 3 is arranged between the two fixed cutting structures 2 and 2', such as: Figure 15 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com