Mixed vortex strip eliminating device for draft tube

A draft tube and vortex elimination technology, which is applied in the direction of pipe components, hydropower generation, pipes/pipe joints/pipe fittings, etc., can solve problems such as affecting the safe operation of hydropower units, low efficiency of hydro turbine units, insufficient to deal with eddy currents, etc., and achieves a simple structure. , prolong life, maintain economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

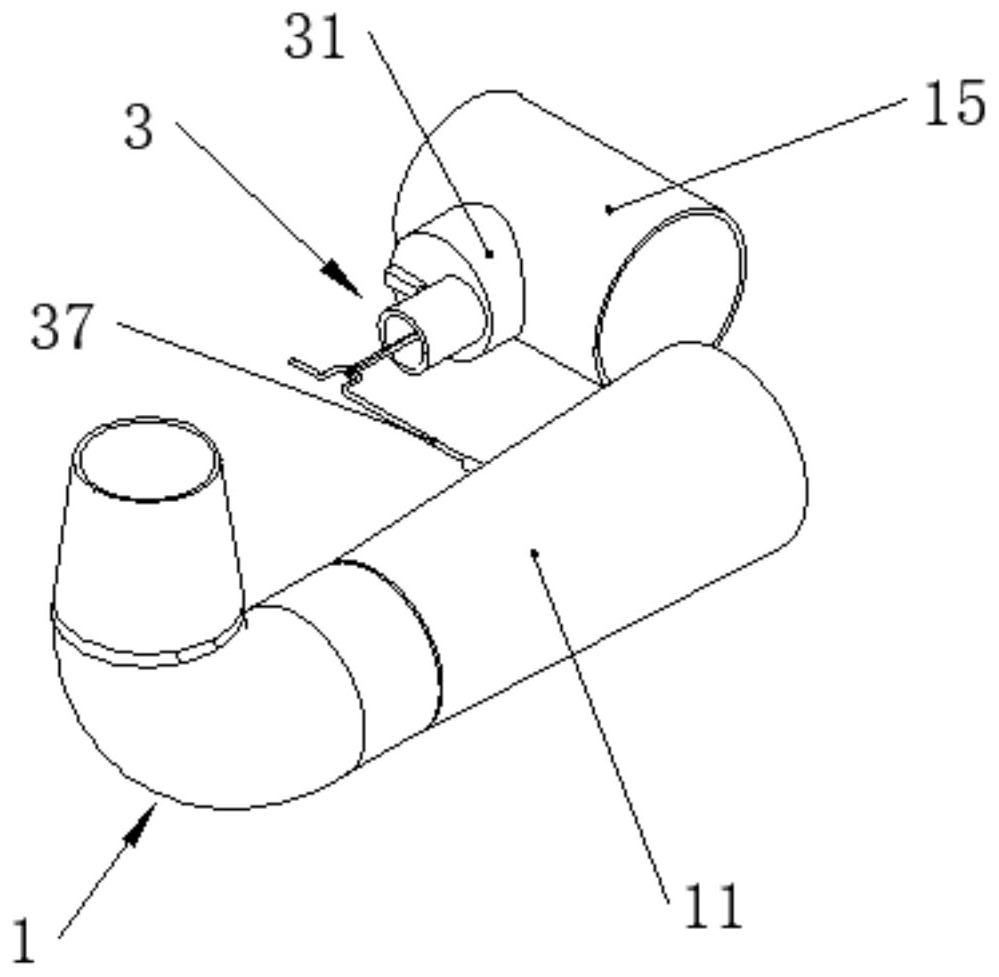

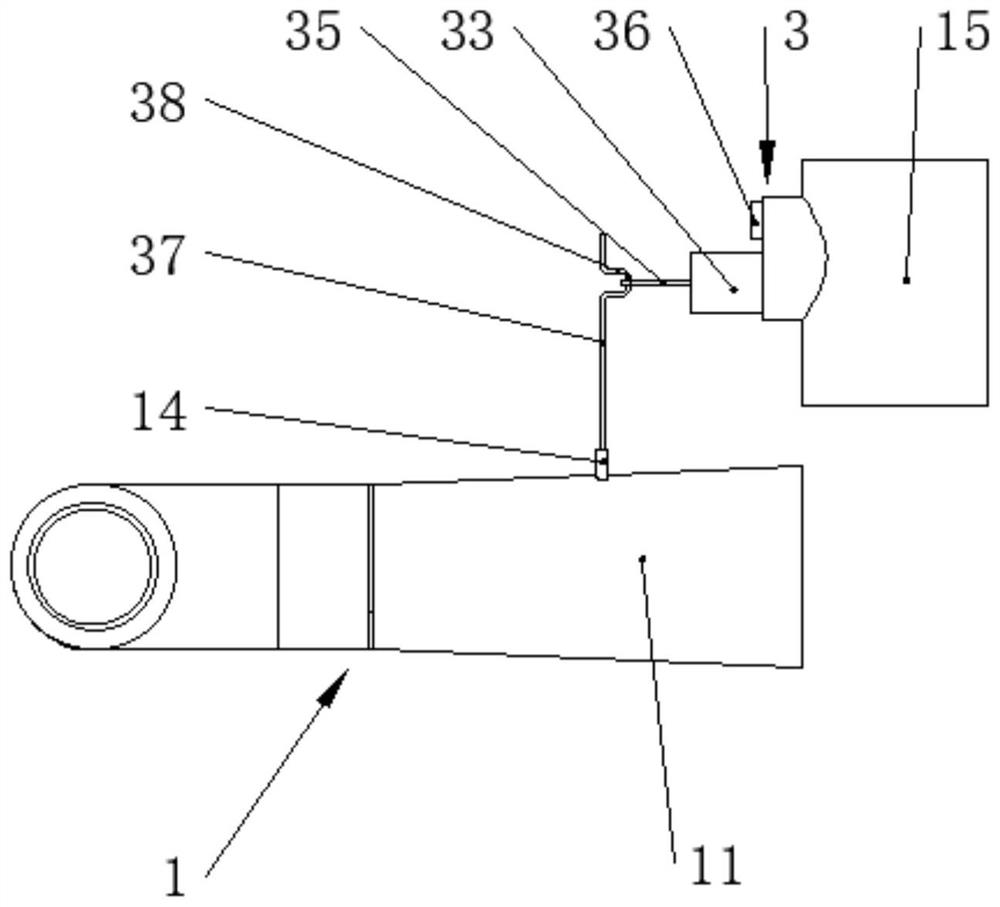

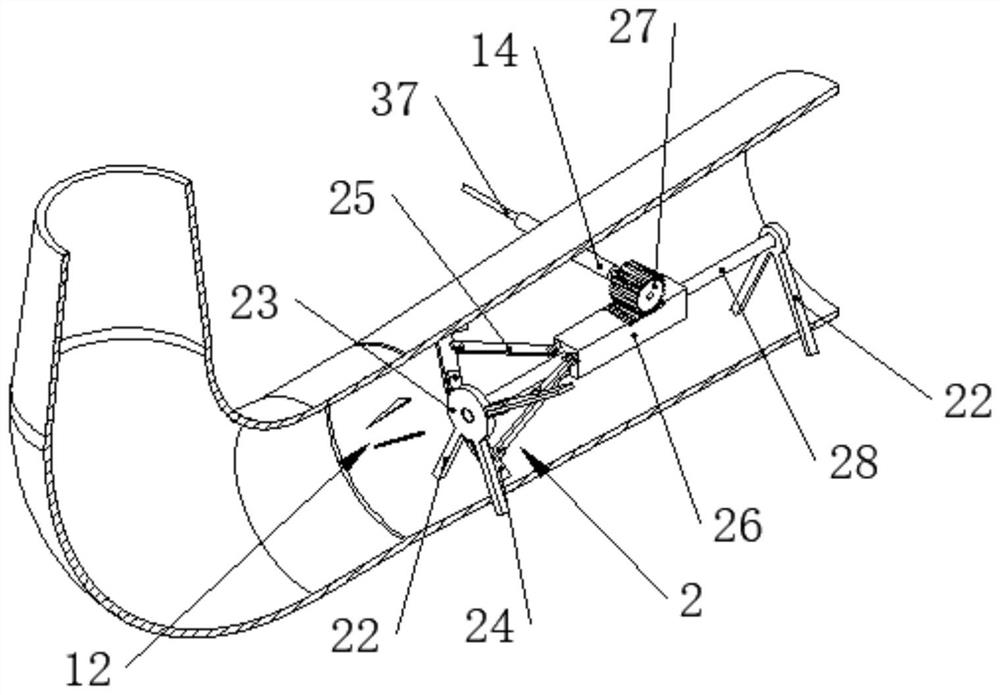

[0037] see Figure 1-10, a device for mixing and eliminating vortex strips of a draft tube, which is arranged in the diffuser section 11 of the draft tube 1, and includes a vortex generator 12 and a vortex elimination device 2; The metal blade 13 on the inner peripheral wall of the diffuser section 11; the vortex elimination device 2 is located at the rear side of the vortex generator 12; the vortex elimination device 2 includes an umbrella-shaped vortex elimination mechanism 21 and a fixed bracket 22; The vortex elimination mechanism 21 includes a base 23 and a vortex elimination plate 24; the fixing bracket 22 is vertically fixed on the inner peripheral wall of the diffuser section 11; the base 23 is fixed on the fixing bracket 22; the base 23 is located on the central axis of the diffuser section 11; at least three front ends of the vortex ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com