Periodic variable-temperature baking method for promoting tobacco leaf yellowing in yellowing period

A technology of variable temperature baking and yellowing period, which is applied in the fields of tobacco, tobacco processing, and tobacco preparation, etc. It can solve the problems of unfavorable activity, affecting the efficiency of tobacco leaf baking, and the quality of tobacco leaves, so as to save the cost of baking, shorten the baking time, The effect of promoting the yellowing of tobacco leaves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

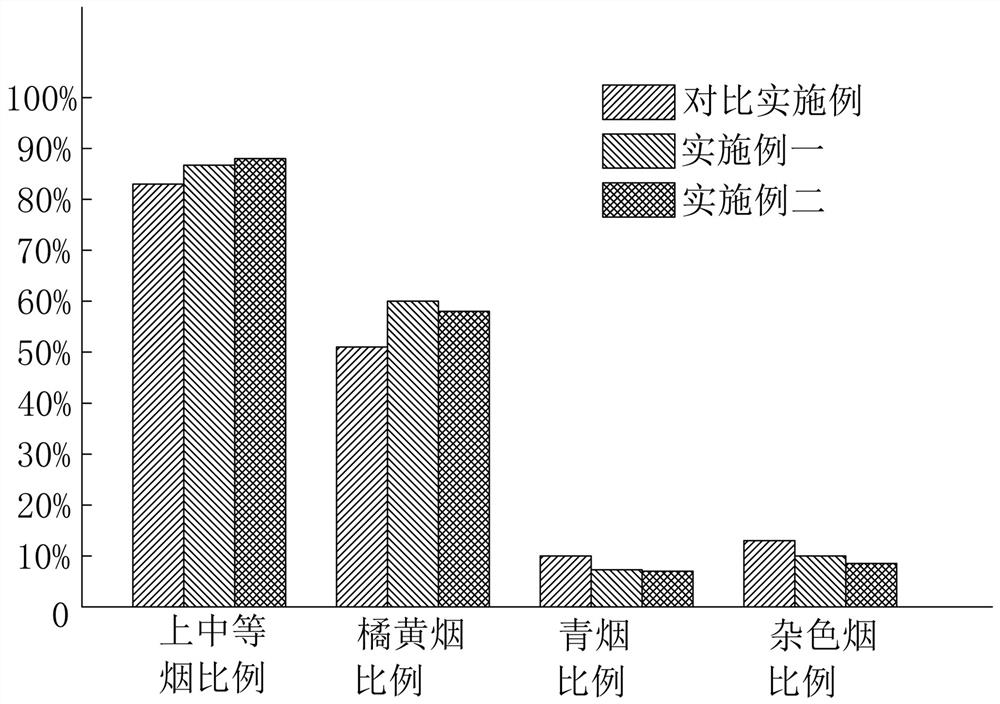

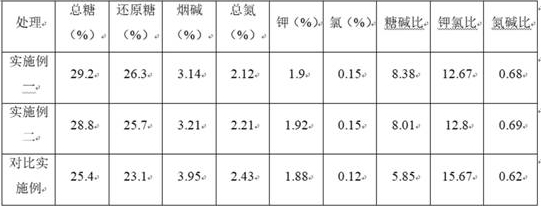

[0033] The present embodiment takes the upper tobacco leaf (15~ 16 leaf position) of the 87 variety of Yunyan as the test material, and adopts the yellowing period of the present invention to change the temperature baking method to bake the test material.

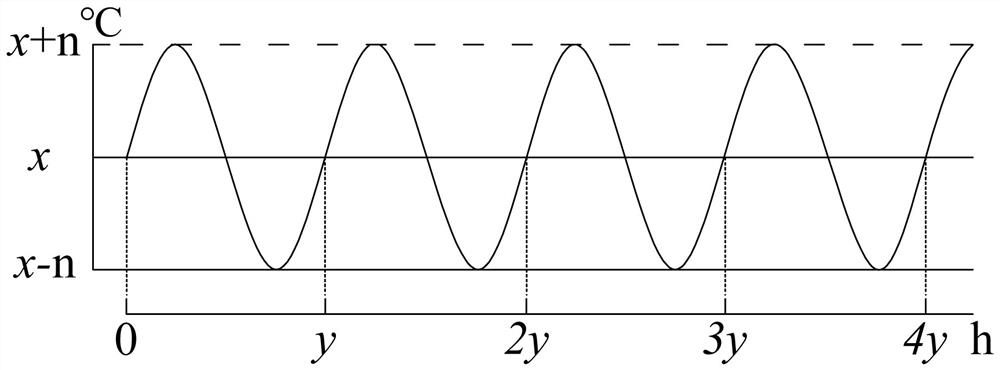

[0034] A kind of promotion of tobacco yellowing period periodic temperature baking method, in the tobacco leaf yellowing period, through the dense roasting room of the tobacco leaf baking control instrument to control the heating device of the dense baking room, in order to facilitate the control of the heating device, the heating device of the present invention adopts a heat pump with high temperature sensitivity, so that the dry bulb temperature of the dense baking room is based on the yellowing temperature of the tobacco leaf x ° C, x are: the leaf tip becomes yellow Baking temperature 36 ° C, the blade 70 ~ 80% yellow Baking temperature 38 ° C, the blade 90% yellow baking temperature 40 ° C, The leaf leaves are all yellow b...

Embodiment 2

[0048] Repeat example one, there are the following different points: through the dense roasting room tobacco roasting control instrument to control the heating device of the dense baking room, so that the dry bulb temperature of the dense baking room to the tobacco leaf yellowing temperature x ° C as the base point temperature, x are: leaf tip yellow baking temperature 36 ° C, leaf 70 ~ 80% yellow baking temperature 38 ° C, leaf 90% yellow baking temperature 40 ° C, leaf full yellow baking temperature 42 ° C, n ° C as the temperature range, n is 0.5 ~ 1.5 ° C, to y hours as the temperature change cycle, y is 2 ~ For 6 hours, the sinusoidal curve changes periodically, and the tobacco leaves in the smoking room are roasted by the baking method of periodic temperature change. The specific process steps are as follows:

[0049] Step S1: Leaf tip yellowing phase during the yellowing phase of tobacco leaves

[0050] Step S11: Set the dry bulb temperature of the filling chamber at the yell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com