Catalyst as well as preparation method and application thereof

A catalyst and modification technology, applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as the inability to achieve benzene conversion, cyclohexylbenzene selectivity, cyclohexylbenzene yield reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The present invention also provides the preparation method of the catalyst described in the above technical solution, comprising the following steps:

[0043] The modified molecular sieve is loaded in a mixed solution of soluble noble metal salt and soluble transition metal salt to obtain a precursor;

[0044] The precursor is calcined to obtain the catalyst.

[0045] In the present invention, unless otherwise specified, all preparation raw materials are commercially available products well known to those skilled in the art.

[0046] In the present invention, the modified molecular sieve is placed in a mixed solution of a soluble noble metal salt and a soluble transition metal salt for loading to obtain a precursor.

[0047] In the present invention, the loading is specifically after mixing soluble noble metal salt, soluble transition metal salt, polyvinylpyrrolidone and water, adding the modified molecular sieve, and finally adding urea to carry out a hydrothermal rea...

Embodiment 1

[0060] First, 4g of ammonium-type Y-type molecular sieve (SiO 2 / Al 2 O 3 =5) vacuum drying at 100°C for 4h; then placed in a quartz fixed bed reactor, and a mixed gas of water vapor and air (volume concentration of water vapor is 10%) was introduced at 300°C, and the flow rate of the mixed gas was 200mL / min, After steam treatment for 2h, switch to pure N 2 , the sample was purged to room temperature at a flow rate of 200 mL / min to obtain a modified hydrogen type Y molecular sieve (denoted as HY-300-2-200);

[0061] 0.99g NiCl 2 ·6H 2 O. 8×10 -4 g PdCl 2 , 0.28g of polyvinylpyrrolidone (PVP) and 30g of deionized water were mixed, 2g of the modified hydrogen-type Y-type molecular sieve was added, and finally 2.58g of urea was added. , followed by solid-liquid separation, washing and drying to obtain a precursor;

[0062] The precursor is calcined, and the calcination process is to raise the temperature to 500°C at a heating rate of 2°C / min, and then keep the temperature...

Embodiment 2

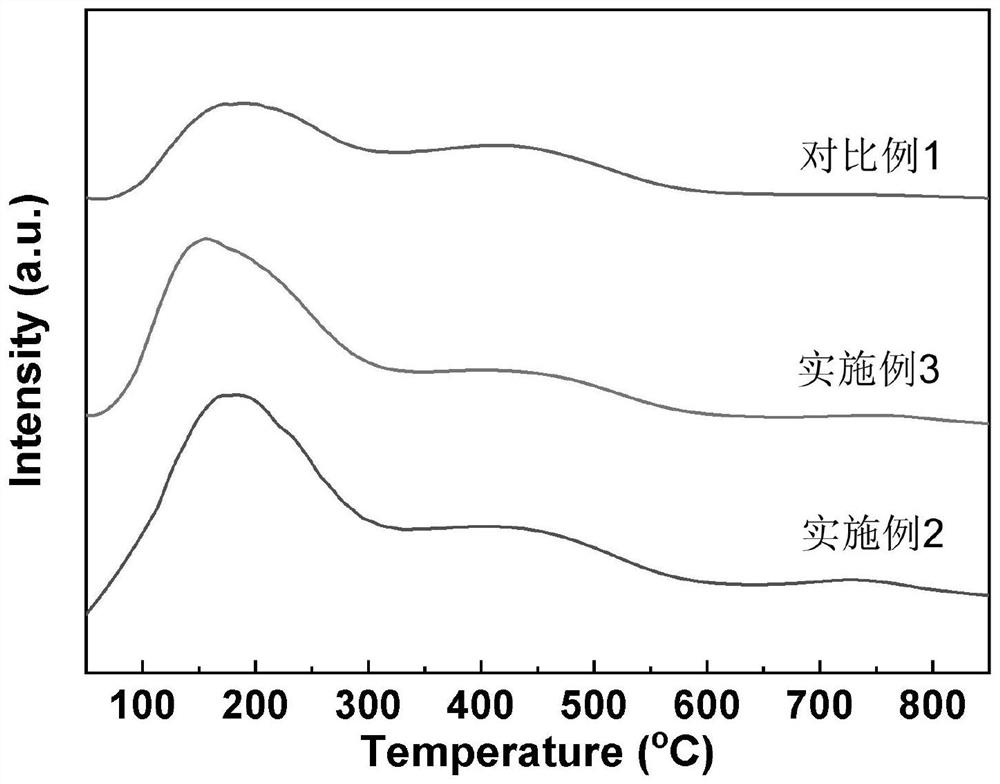

[0064] Referring to Example 1, the only difference is that the temperature of the steam treatment is 500° C., and the obtained modified hydrogen type Y-type molecular sieve (denoted as HY-500-2-200).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com