System for producing high-quality gasoline by coupling naphtha and methanol and preparation method thereof

A naphtha, high-quality technology, used in hydrocarbon oil treatment products, petroleum industry, hydrocarbon oil treatment, etc., can solve the problems of high operating costs, high benzene and sulfur content, unstable product quality, etc., to reduce the amount of production , increase the desulfurization function, improve the effect of desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

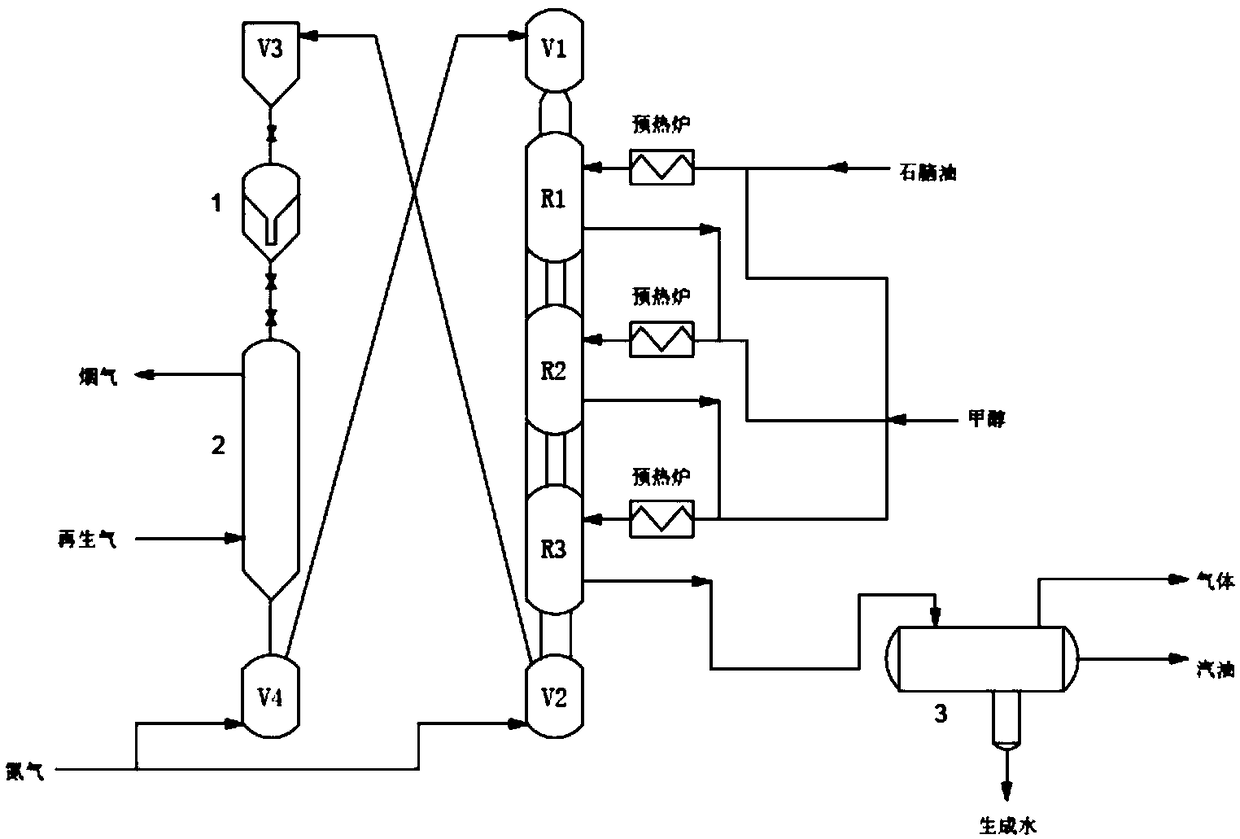

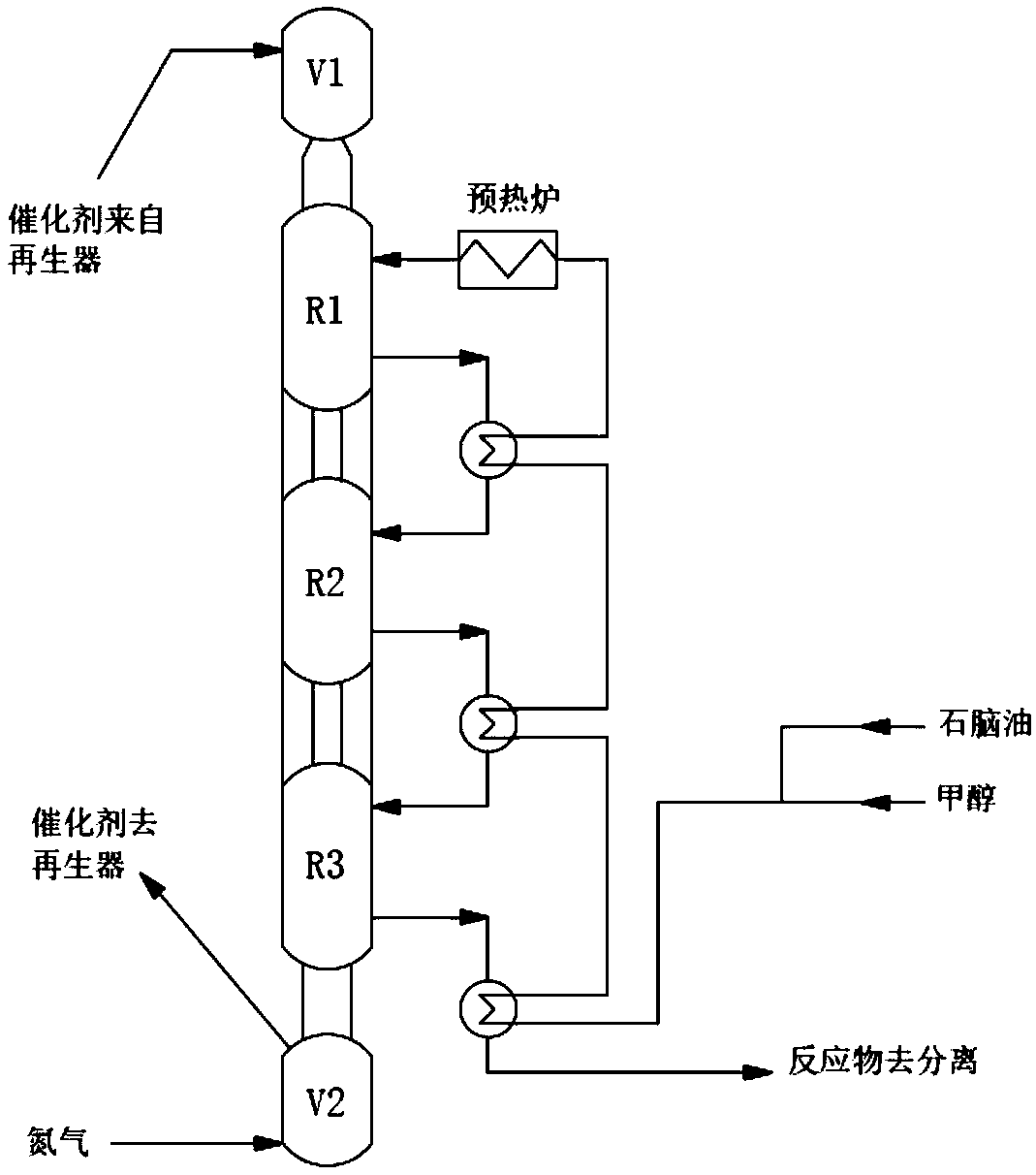

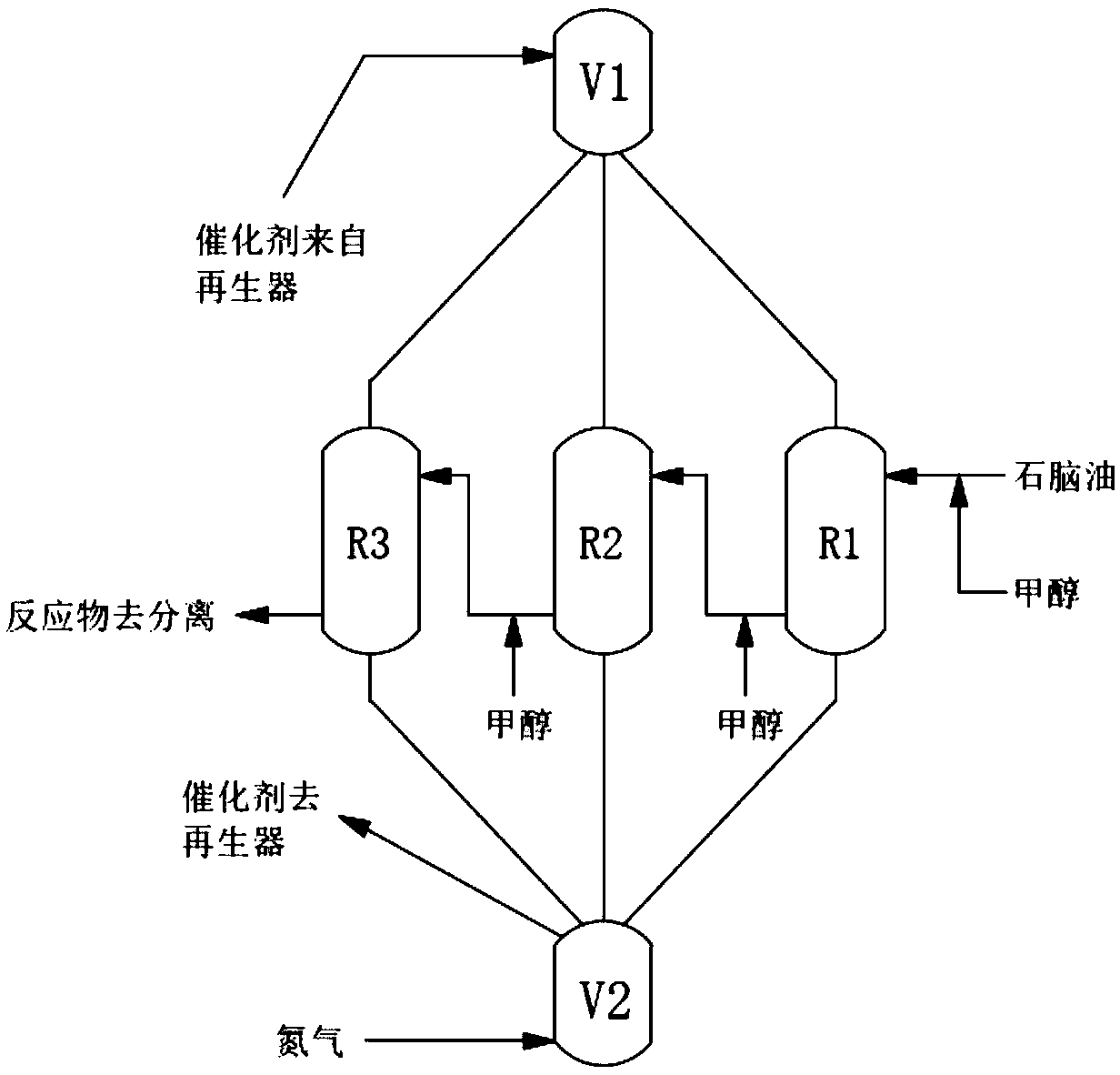

Method used

Image

Examples

Embodiment 1

[0046] Molecular sieve modification: Take 1200g of commercially available HZSM-5 molecular sieve with a silicon-aluminum ratio of 60, mix it with 2000mL of a solution containing 105g of zinc nitrate, 30g of nickel nitrate, 38g of lanthanum nitrate, and 12g of ammonium molybdate. Stir and exchange for 1 hour, then filter, dry the filter cake at 120°C for 3 hours, and bake at 550°C for 5 hours. Then the modified HZSM-5 molecular sieve can be obtained.

[0047] Catalyst preparation: pulverize the modified molecular sieve and carrier pseudo-boehmite and mix them well, ball mill to 400-1000 mesh, add to rolling forming kettle, dilute the binder and water according to the ratio of 1:5-1:10 , Spray intermittently into the mixture of molecular sieve and carrier through atomizing equipment, roll and shape continuously until it is shaped into a small ball with a diameter of 1-2mm, then dry at 70-130°C for 2 hours, and bake at 500°C for 4 hours , hydrothermally treated at 500°C for 2.5 ...

Embodiment 2

[0049] Catalyst B was obtained by taking 1200 g of commercially available HZSM-5 molecular sieve with a silicon-aluminum ratio of 25, and using the same active metal formula and preparation process as in Example 1.

Embodiment 3

[0051] Using the same catalyst and formula as in Example 1, the difference is that the quality of zinc nitrate in the molecular sieve modification solution is changed to 52g, the quality of nickel nitrate is changed to 71g, the quality of lanthanum nitrate is changed to 75g, and the quality of ammonium molybdate is changed to 20g Other preparation process Invariably, catalyst C was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com