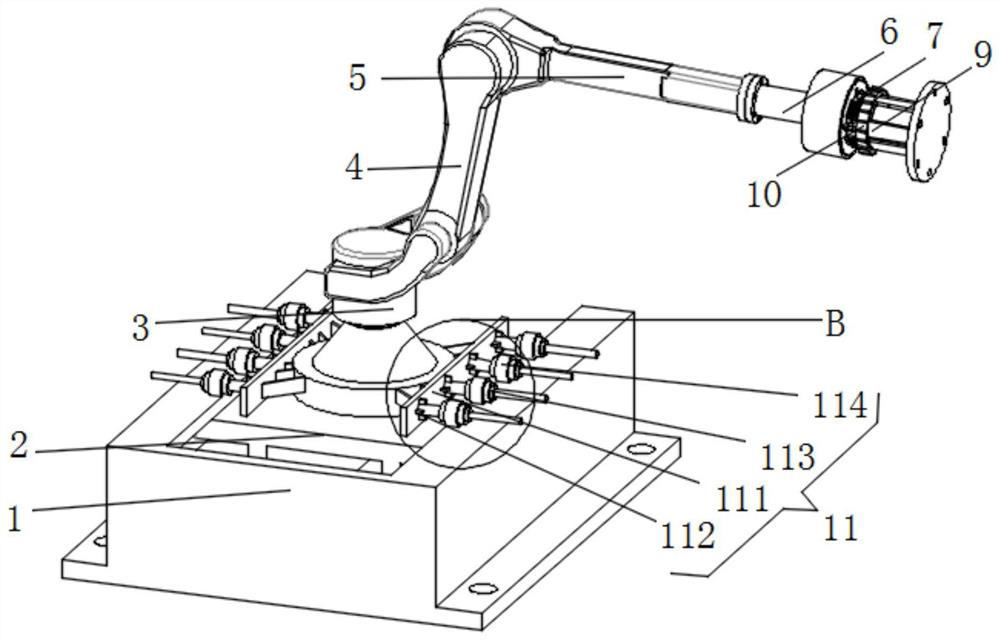

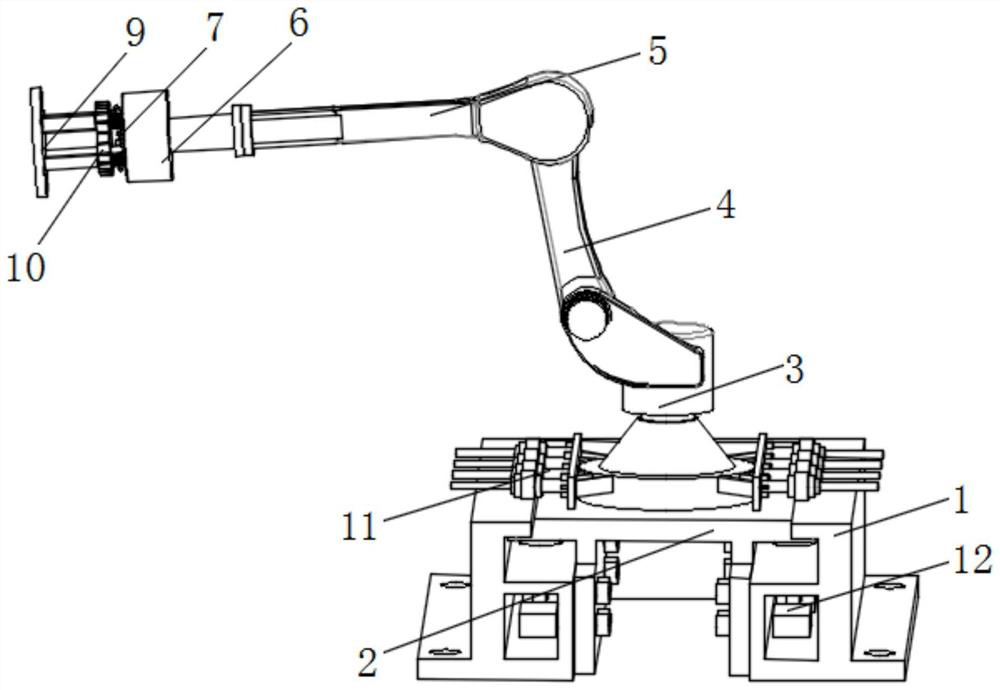

Industrial robotic arm for controlling industrial numerical control machine tool

A technology for CNC machine tools and industrial machines, applied in the field of robotic arms, can solve problems such as time-consuming, claw maintenance or replacement process troublesome, and lower overall equipment use efficiency, to achieve the effect of improving use efficiency and shortening operation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

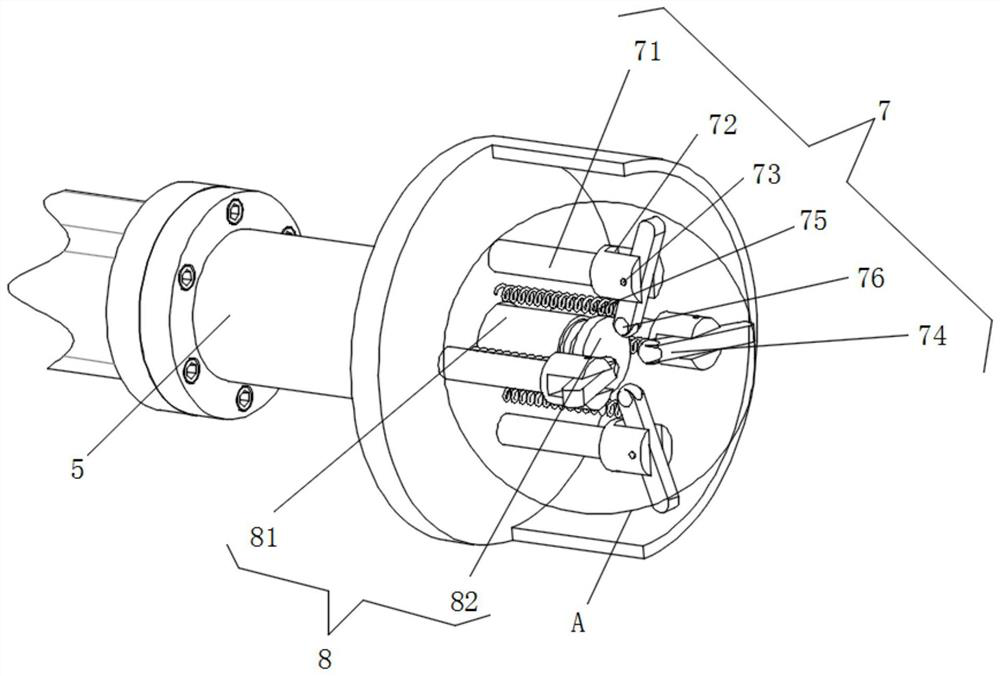

[0033] When it is necessary to provide installation for the jaw, the connection socket 91 set inside the compression support member 91 may first be in the gap between the inner side of the extension sleeve 6 and the clamping member 7, and during the insertion process, in order to avoid the clamping rod 74 interfering with the movement of the connecting socket 91, the clamping lever 74 may be flipped at the beginning of the set of the connecting socket 91, so that the clamping lever 74 is parallel to the extension sleeve 6, the first compression spring 75 at this time is compressed, after the connection socket 91 set to the inside of the extension sleeve 6, Start clamping the electric pushrod 81 inside the power member 81, and then by the electric push rod 81 inside the telescopic rod push magnet top plate 82 for linear movement, and the magnet top plate 82 during the movement will be in contact with the metal sphere 76 inside the clamping member 76 and top pressure, and finally th...

Embodiment 2

[0035]When the overall equipment in the process of use due to vibration or due to improper operation and impact, at this time the two sets of displacement monitoring mechanism 11 inside the multiple top pressure rod 112 and the pressure sensor 113 between the connection will be displaced intermittently, the specific pressure value change of a plurality of pressure sensors 113 combined to see, reflecting the bottom of the robot arm 3 in the use of the process of displacement changes relative to the original coordinates of the zero point and the specific number of pressure rods 112 and pressure sensor 113 according to the actual use needs set.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com