Flexible combined packaging gift box printing production equipment

A technology for production equipment and gift boxes, which is applied in printing, printing machines, biological packaging, etc., can solve the problems of staff influence, inability to protect, and pigment treatment, so as to reduce the possibility of accidental damage, improve protection ability, and improve environmental protection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

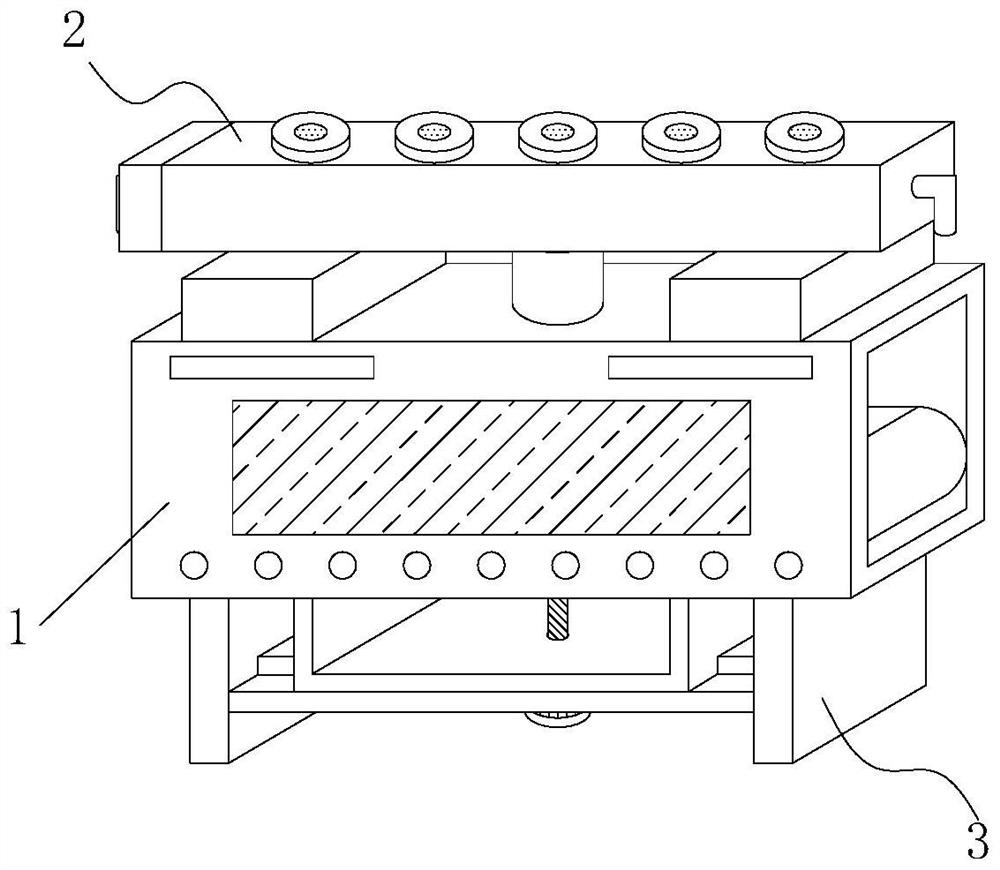

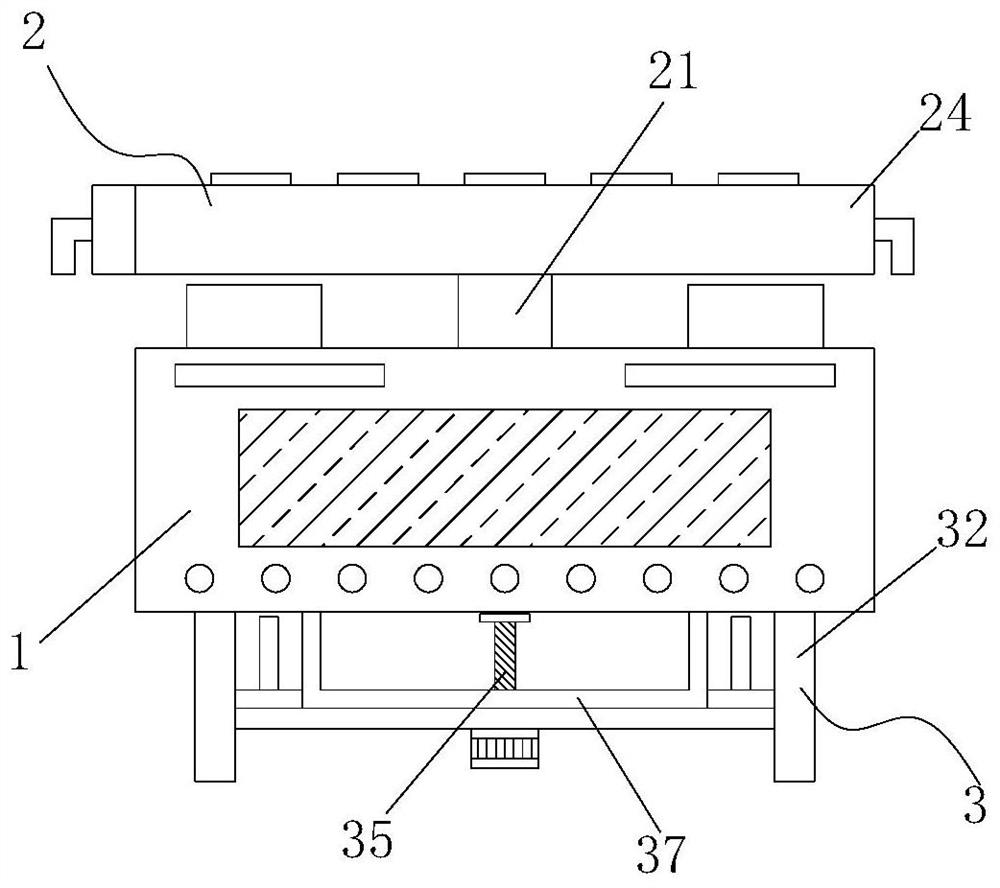

[0025] see Figure 1-4 The present invention provides the following technical solutions: a flexible combined packaging gift box printing production equipment, comprising a flexible combined packaging gift box printing production equipment main body 1, and a processing device 2 is provided on the top of the flexible combined packaging gift box printing production equipment main body 1;

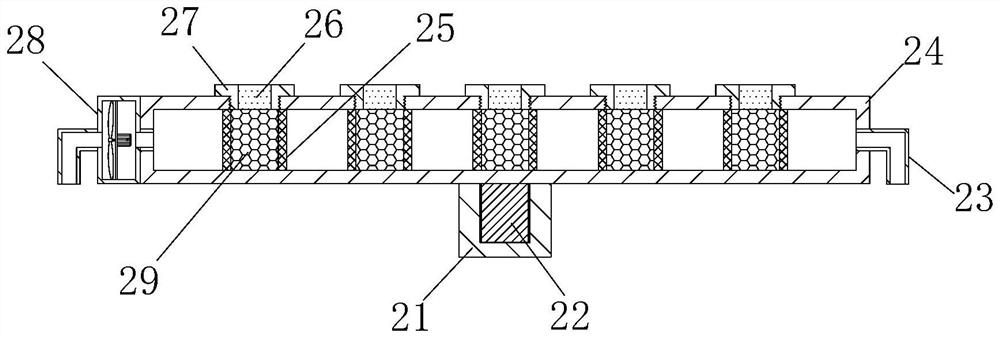

[0026] The processing device 2 includes an air inlet pipe 23, a processing box 24, a mesh cylinder 25, a fan 28 and an activated carbon 29. A processing box 24 is arranged above the main body 1 of the flexible combined packaging gift box printing production equipment, and an inlet pipe 23 is installed on one side of the processing box 24. , a fan 28 is installed on the side of the processing box 24 away from the air intake pipe 23 , a plurality of mesh cylinders 25 are installed on the inner side of the processing box 24 , and the inner side of the mesh cylinder 25 is filled with activated carbo...

Embodiment 2

[0035] The difference between this embodiment and Embodiment 1 is that an adjustment device 3 is provided under the main body 1 of the flexible combined packaging gift box printing production equipment, and the adjustment device 3 includes a motor 31, a support plate 32, a screw rod 35, a moving frame 37 and a fixed plate 38. Two support plates 32 are arranged under the main body 1 of the flexible combined packaging gift box printing production equipment, a fixing plate 38 is installed between the two support plates 32, a motor 31 is installed under the fixing plate 38, and a motor 31 is installed above it. The screw 35, a movable frame 37 is installed below the main body 1 of the flexible combined packaging gift box printing production equipment and at a position corresponding to the screw 35,

[0036] By adopting the above technical solution, the staff can adjust the height of the main body 1 of the flexible combined packaging gift box printing production equipment by manipul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com