Method for preparing mine cemented filling material by using labor/mining industry solid waste mineralized CO2

A technology for cementing filling materials and cementitious materials, which can be used in solid waste management, sustainable waste treatment, cement production, etc., and can solve problems such as threats to people's lives and property safety, subsidence of underground goafs, and ground tailings storage. , to solve instability, reduce carbon emissions, and achieve the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

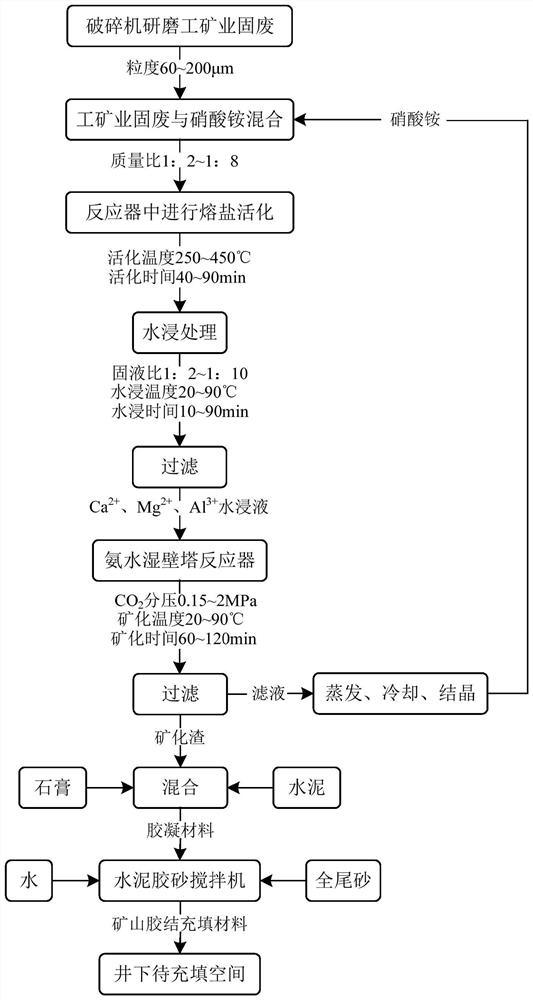

[0028] Please refer to figure 1 Shown, the present invention provides a kind of labor / mining industry solid waste mineralization CO 2 A method for preparing mine cemented filling material, comprising the following steps:

[0029] S1. Grinding industrial / mining solid waste and evenly mixing it with ammonium nitrate;

[0030] S2. Place the mixed raw materials in step S1 in a reactor for molten salt activation, collect the ammonia gas generated during the activation process, and convert the metals including Ca, Mg, and Al in the raw materials into corresponding metals after activation Nitrate;

[0031] S3, the metal nitrate activation mixture obtained in step S2 is subjected to water immersion treatment, and the main component obtained after fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com