High-temperature-resistant distributed buffer insulation sheet and notebook computer

A distributed, high-temperature-resistant technology, applied in insulation improvement, electrical digital data processing, film/sheet release coating, etc., can solve the problem of functional need to be further expanded, achieve good insulation, improve product quality, overall structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

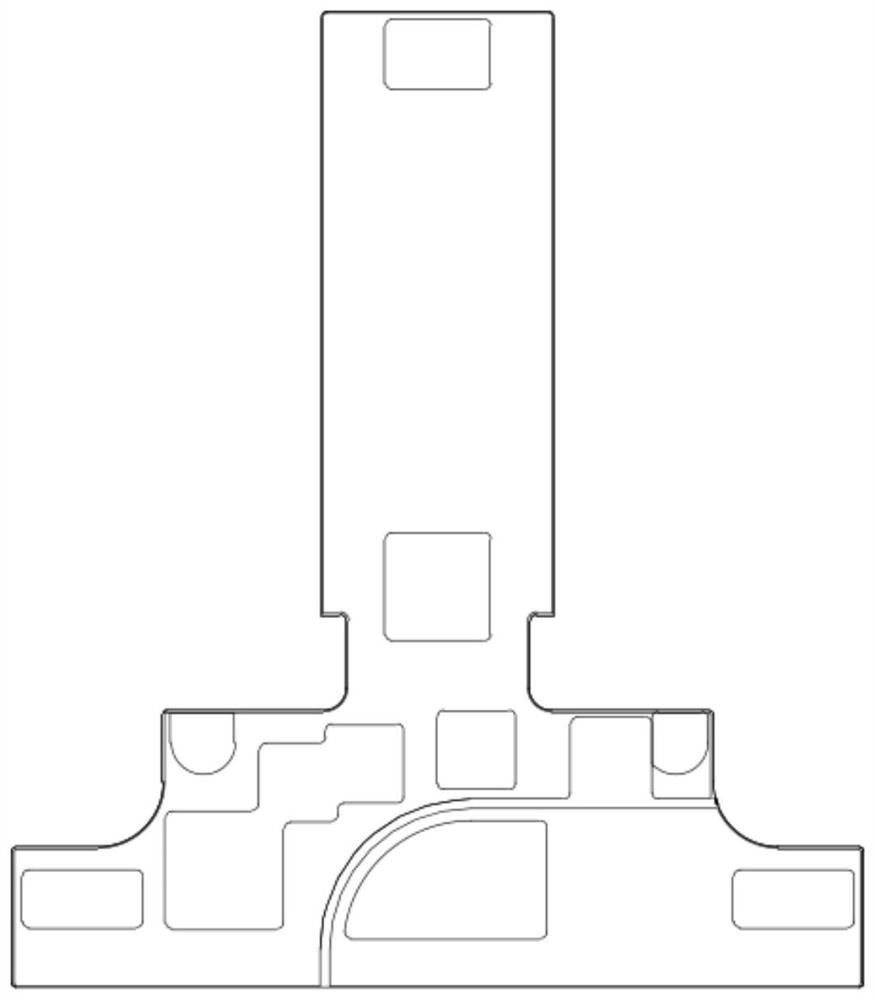

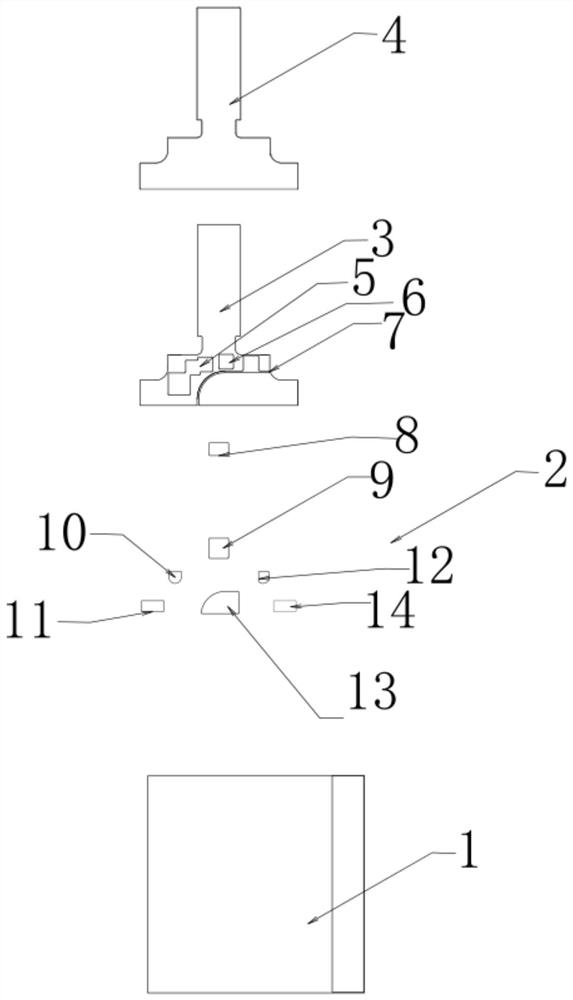

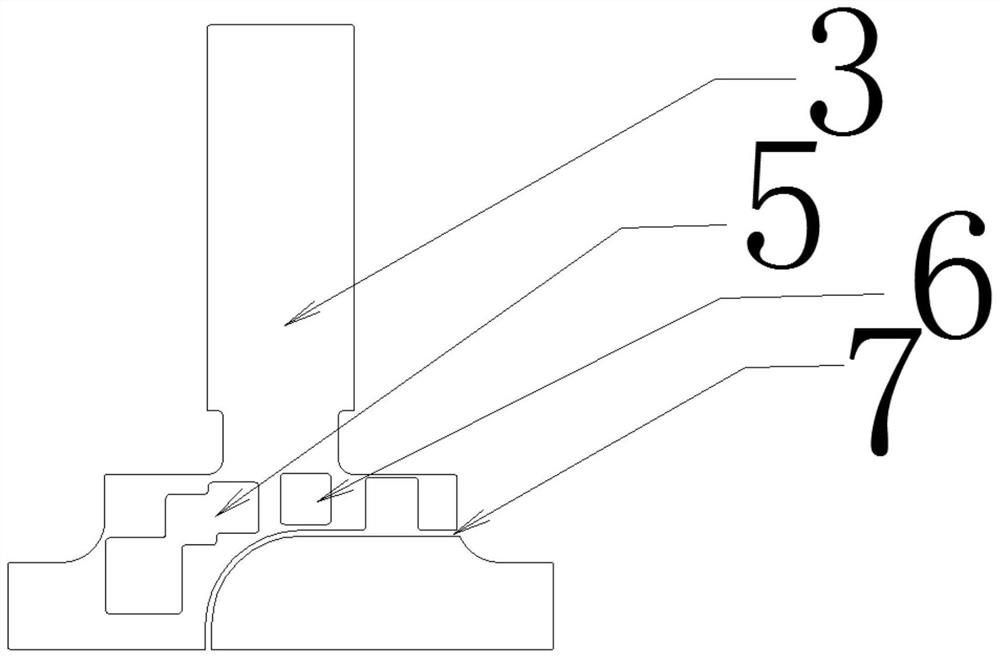

[0028] like Figure 1-3 As shown, a high temperature resistant distributed buffer insulating sheet includes a release film 1, a foam double-sided adhesive group 2, a PC film 3 and a PI tape 4, which are arranged in order from bottom to top and are matched. The opposite sides of the group 2 are sticky, one side of the foam double-sided adhesive tape group 2 is bonded to the PC film 3 by adhesiveness, and the opposite side of the foam double-sided adhesive tape group 2 is bonded to the release film 1 by adhesiveness. The cotton double-sided tape group 2 includes several foam double-sided tapes with different structures (different shapes, thicknesses, hardnesses, sizes, etc.) At the position, the PC film 3 is non-adhesive, a number of gaps with different structures (including shapes, sizes, etc.) are opened on the PC film 3, the PI tape 4 has a T-shaped structure and several step structures are arranged on it, and the PI tape 4 faces the PC film. One side of 3 is sticky, the sid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com