Intelligent control ventilation system for tunnel construction

A technology of intelligent construction and ventilation system, applied in mine/tunnel ventilation, pump control, machine/engine, etc., can solve problems such as complex environment, poor timeliness, and damage to air ducts, and achieve accurate flow measurement and high intelligence. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the above objects, features and advantages of the present invention more obvious and easy to understand, specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

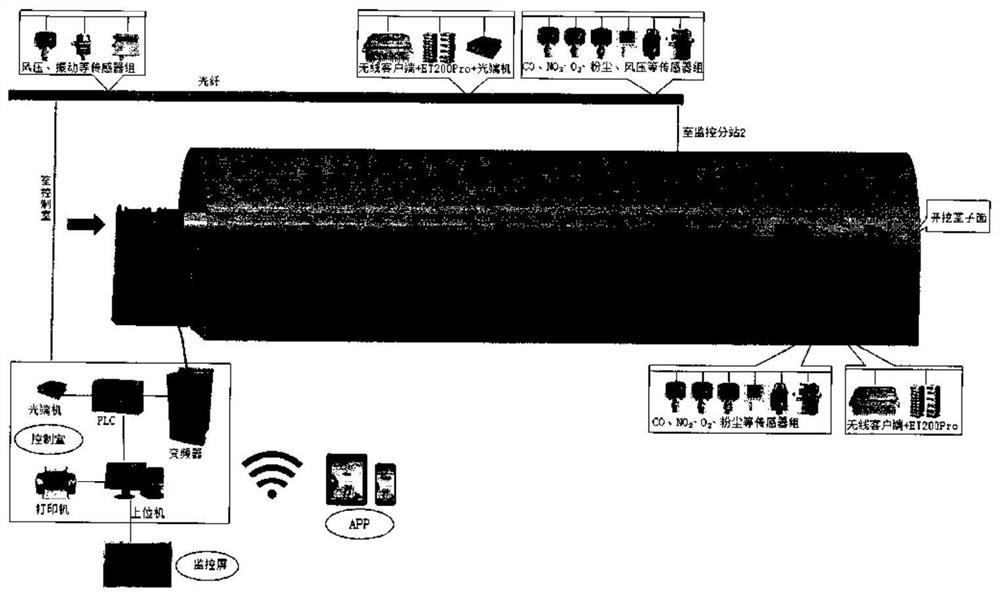

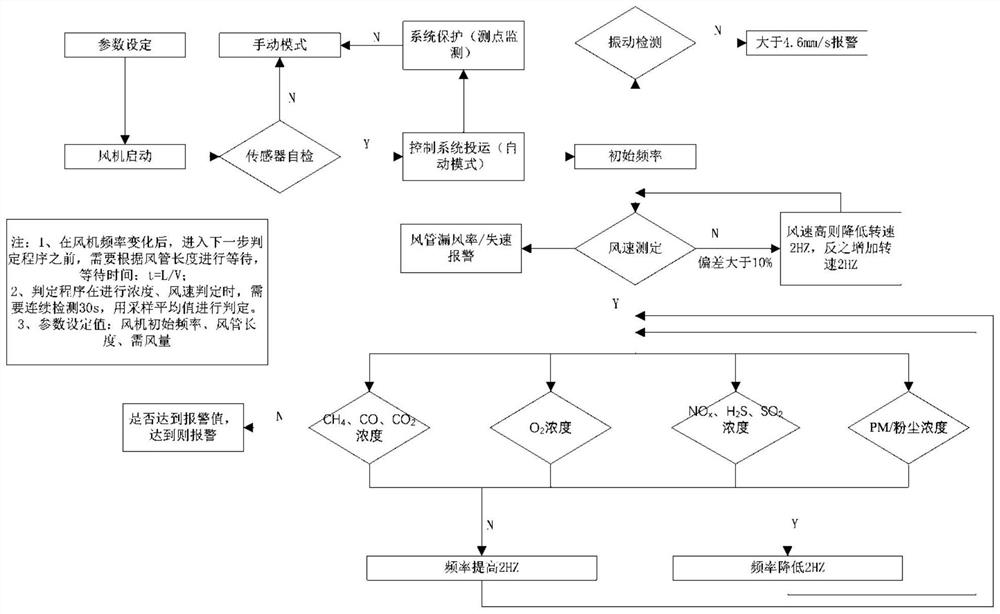

[0033] like figure 1 As shown, the present invention provides an intelligent control ventilation system for tunnel construction, the system mainly includes: monitoring substation 1, monitoring substation 2, hard air duct, fan body including monitoring, control room, APP, and monitoring large screen. The monitoring sub-station 1 is located near the excavation face of the tunnel. Since the tunnel construction involves different procedures such as blasting, slag removal, support, shotcrete, and drilling, the monitoring sub-station is placed on a movable trolley for ease of movement. Above, using UPS battery power supply, substation 1 contains environmental parameters, such as CO, NO 2 , O 2 , dust sensor, temperature and humid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com