Deep coal seam fluidized coal and coal bed gas co-mining and CO2 storage and collection integrated method

A coalbed methane, fluidization technology, applied in drilling equipment and methods, other gas emission reduction technologies, surface mining, etc. Mature and other issues, to achieve the effect of being conducive to rapid drainage and pressure relief and gas production, improving the utilization rate of underground resources, and strong comprehensiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

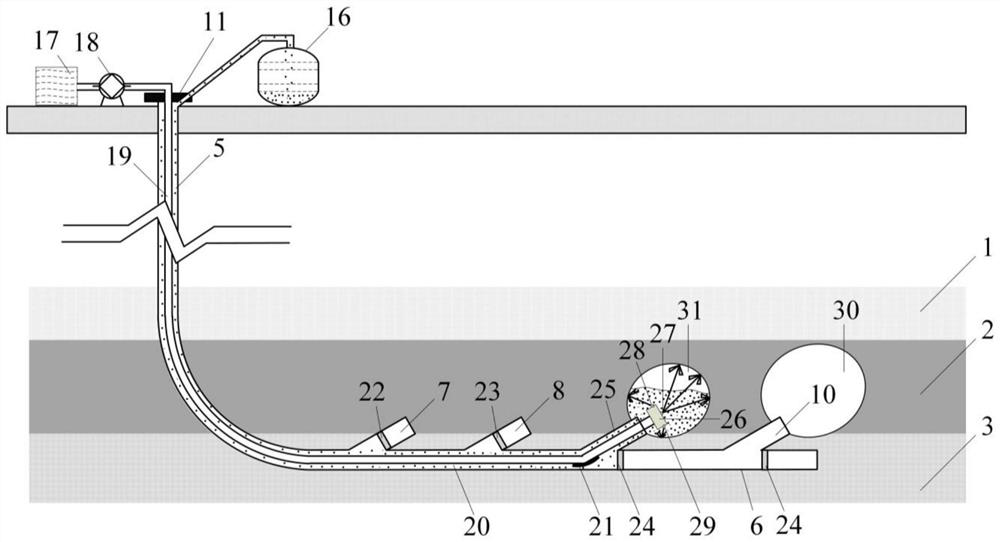

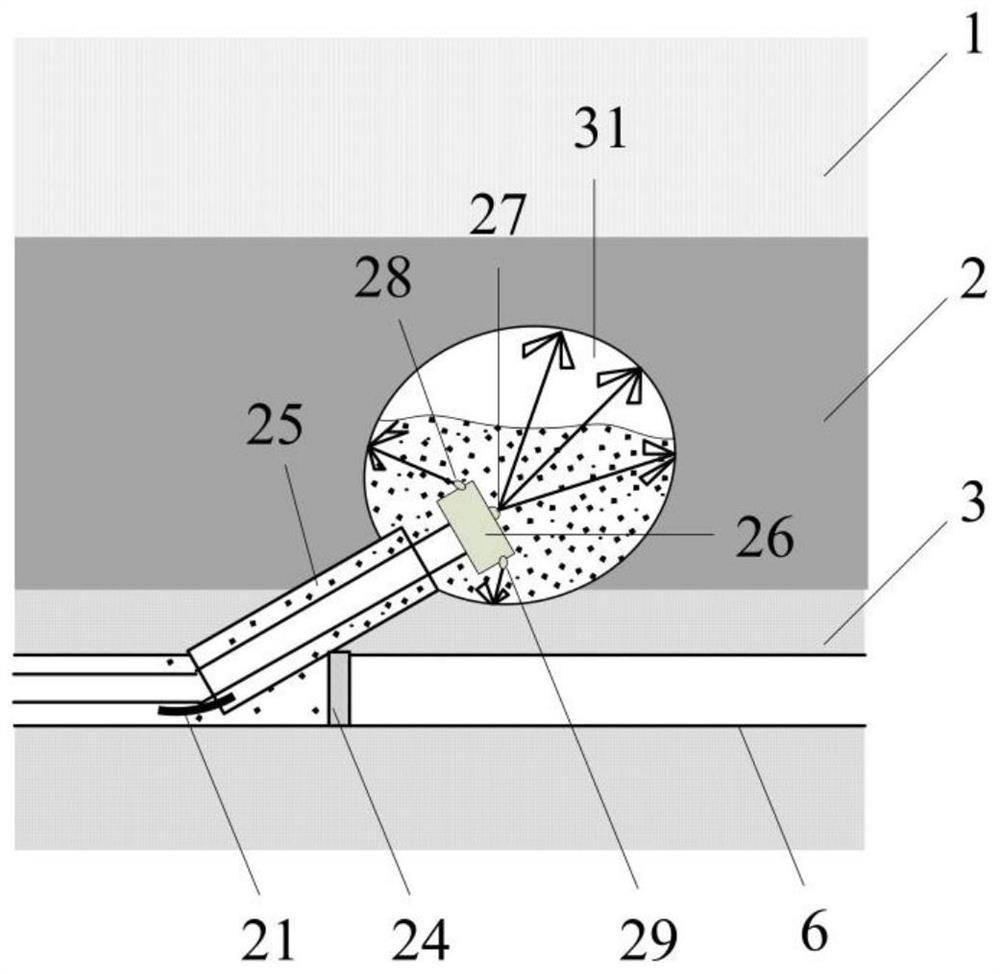

[0036] In the present invention, a deep coalbed fluidized coal and coalbed methane co-mining and CO 2 Reservoir integration method, including multi-lateral horizontal well construction, water jet cavity co-mining and coalbed methane, coalbed drainage and pressure relief and coalbed methane exploitation, CO 2 Injection Reservoir Steps:

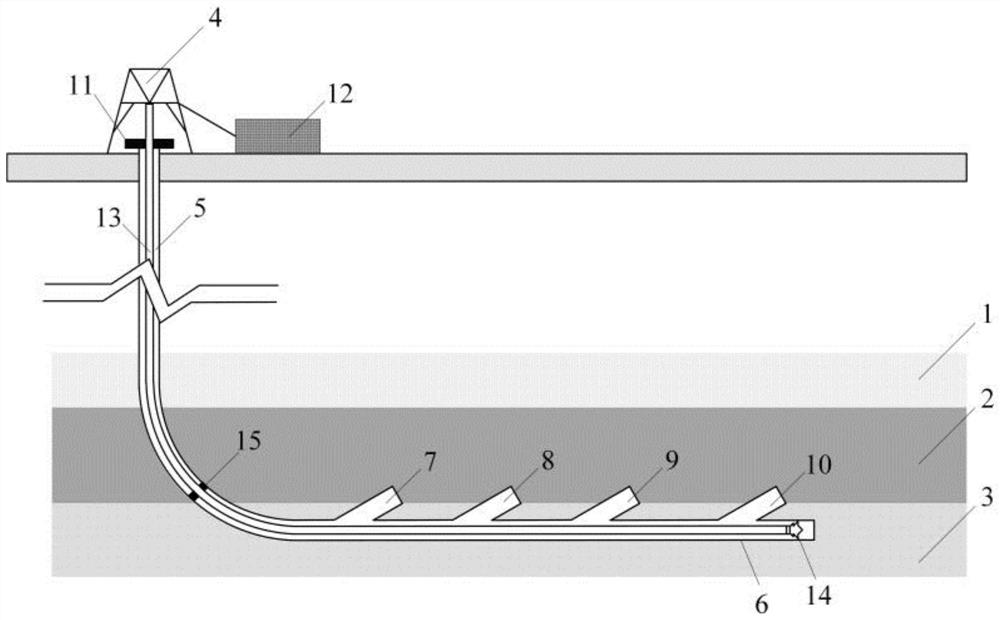

[0037] see attached figure 1 , Multilateral horizontal well construction, using the multilateral horizontal well drilling method, drilling the multilateral horizontal well using drilling equipment, the drilling equipment includes a derrick 4, a drilling string connected to the derrick 4, a wellhead device 11 and a surface device 12, the drilling string It includes a drill pipe 13 , a centralizer 15 arranged between the vertical well and the main horizontal well 6 , and a drill bit 14 arranged at the end of the drill pipe 13 . The main horizontal well 6 is formed along the coal seam floor 3, and a plurality of branch wells 7, 8, 9, and 10 are ...

Embodiment 2

[0043] The difference from Example 1 is that, in order to realize the area development and utilization of the coal seam, and at the same time, there are certain coal pillars in the coal seam for support, so as to ensure the stability of the coal seam and the coal seam cavity. There are multiple, multiple lateral horizontal wells to form cluster wells, and the two adjacent main horizontal wells 6 are staggered, so that the branch wells of the middle main horizontal well 6 are arranged in the four adjacent main horizontal wells 6. between branch wells. Among them, the co-production of fluidized coal and coalbed methane in deep coal seams of each multi-lateral horizontal well and CO 2 The storage integration method is the same as that in Example 1.

Embodiment 3

[0045] The difference from Example 2 is that, in order to improve the utilization rate, after carbon dioxide storage is completed, as needed, the carbon dioxide is converted into production, and the stored carbon dioxide is recovered and used for operations such as carbon dioxide flooding in oil and gas fields.

[0046] In a specific embodiment, in the stage of coalbed methane drainage and pressure relief and coalbed methane exploitation, if the coalbed cavity collapses or collapses, the water jet well washing operation is carried out to break the blocked coal blocks, dredge the wellbore, and then carry out the coalbed methane again. Drainage pressure relief and coalbed methane extraction process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com