Resin type inductor structure

A resin-type, inductive technology, applied in the field of inductors, can solve the problems of many manufacturing processes, complex structures, and complexity, and achieve the effect of reducing the volume, simplifying the manufacturing process, and improving the quality factor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

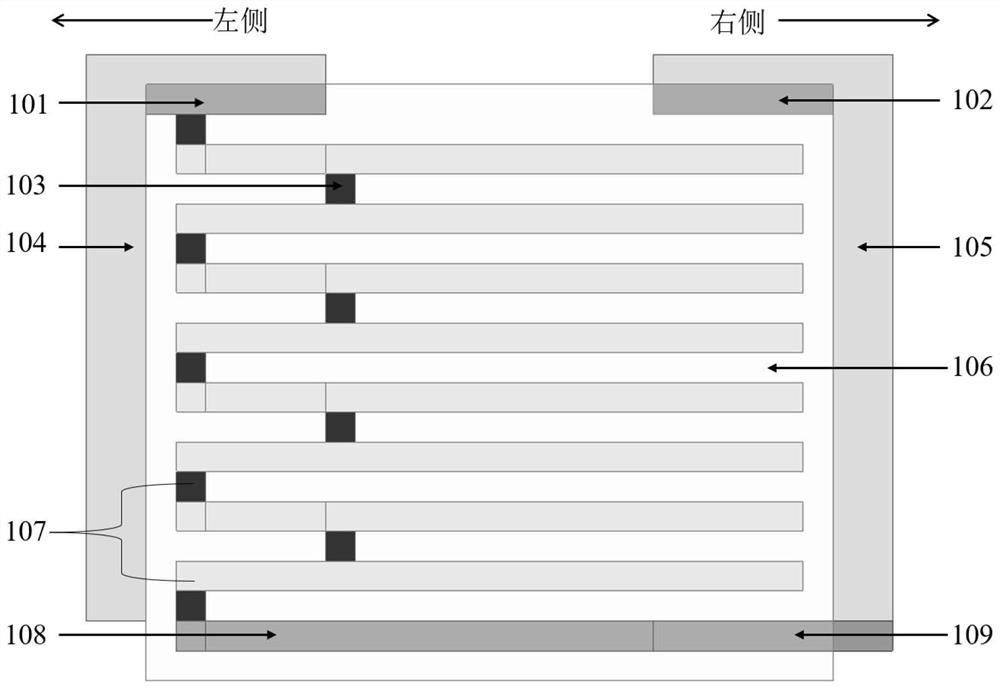

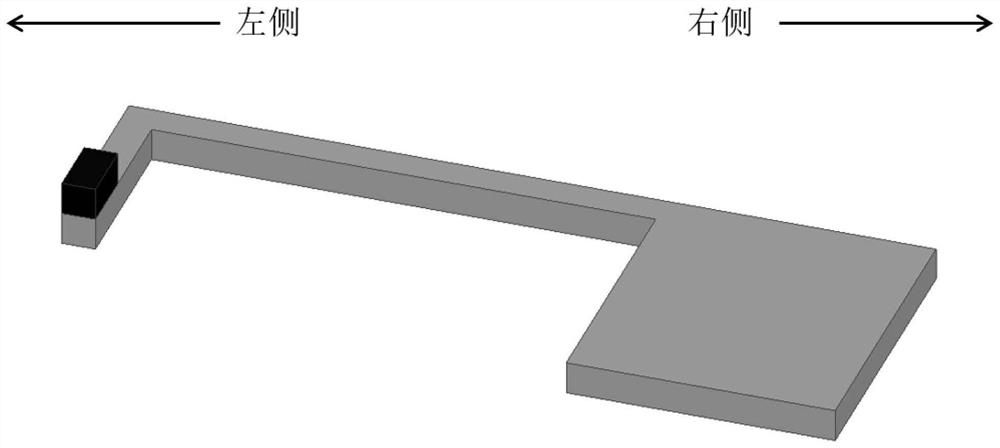

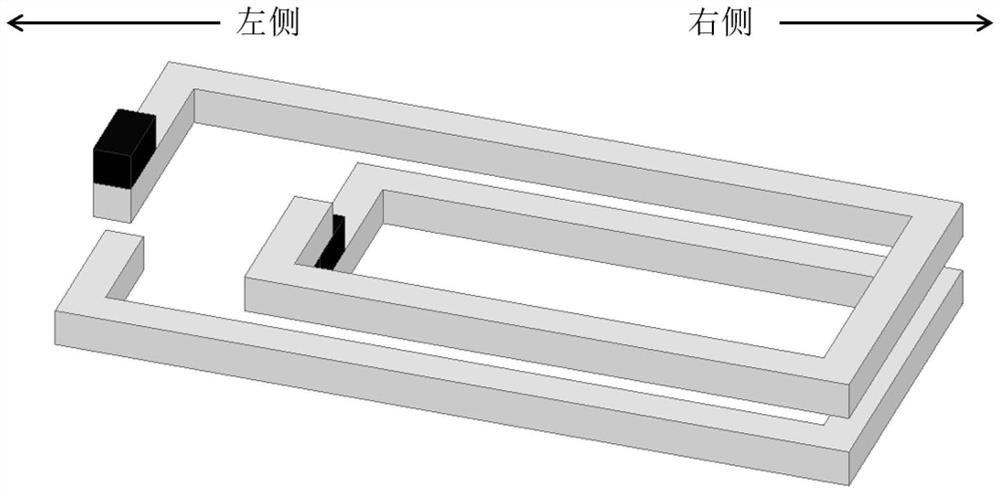

[0026] A resin-type inductor structure, the structure of the resin inductor is composed of copper coils and copper pillars interconnected. In the inductor structure, the left side of the bottom copper coil is connected to the copper pillar, the right side is connected to the copper surface 109, and the bottom copper coil is connected to the copper surface 109, copper The column connections together form the bottom structure of the inductor; and the bottom copper coil is interconnected with the right end electrode 105; the top copper column is interconnected with the top left copper surface 101, and the top left copper surface 101 is interconnected with the left end electrode 104. The top right copper surface 102 is interconnected with the right terminal electrode 105;

[0027] The inductor structure includes N basic coil units 107 in the middle. Each basic coil unit 107 includes an upper layer coil, a lower layer coil and two copper pillars. The copper pillars are arranged betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com