Crushing device convenient for producing small-molecule active selenium peptide

A pulverizing device and technology of active selenium, applied in solid separation, wet separation, cocoa and other directions, can solve the problems of pulverizing soybean meat, inability to separate soybean skin and soybean meat, reducing the quality of enzymatic hydrolysis of soybean meat, etc., to ensure the efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be further described below in conjunction with drawings and embodiments.

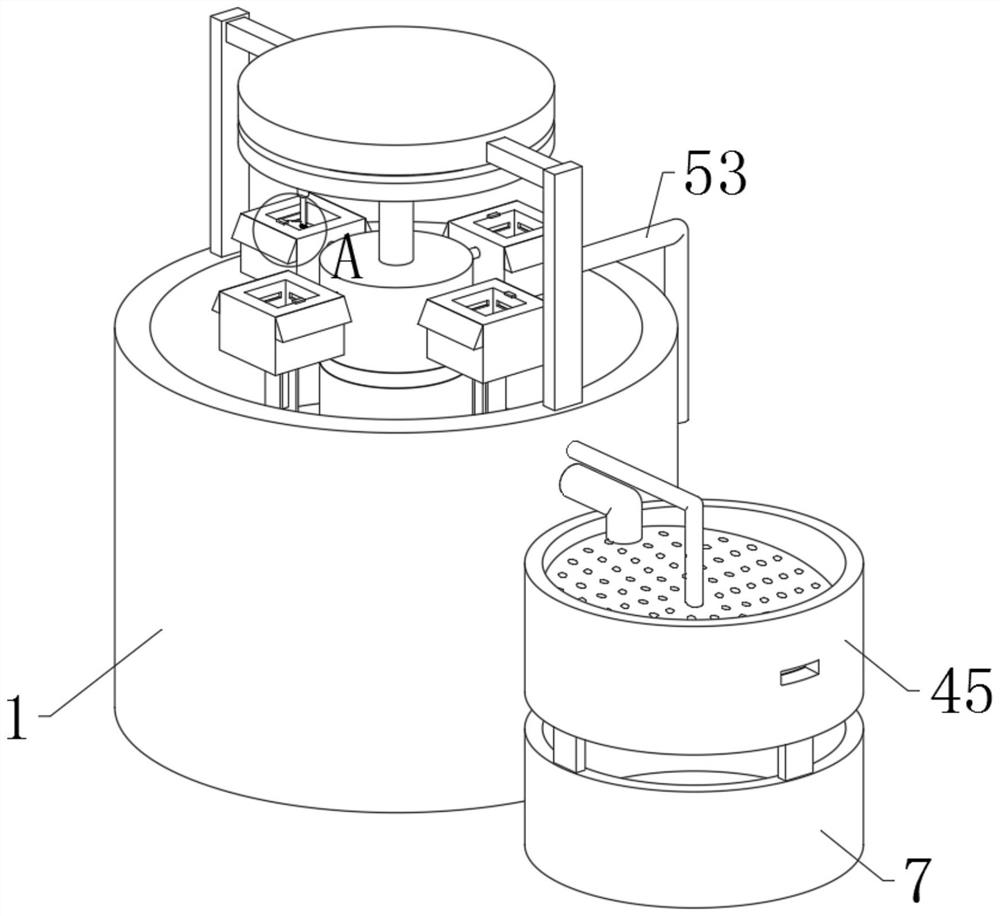

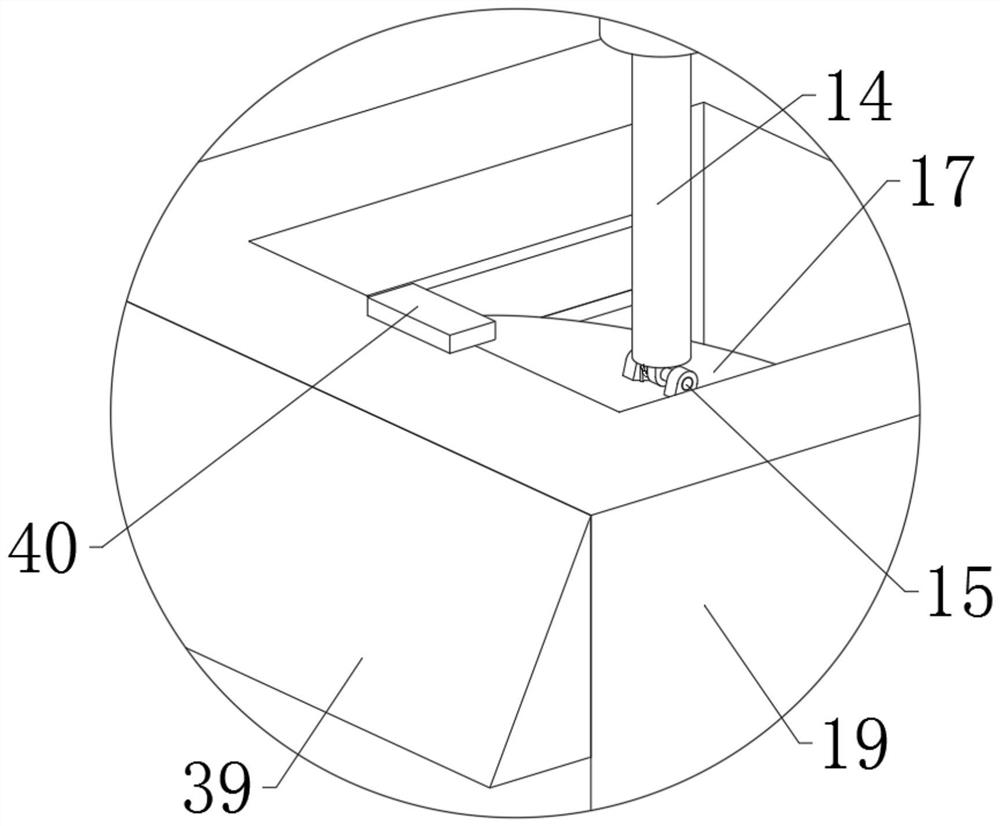

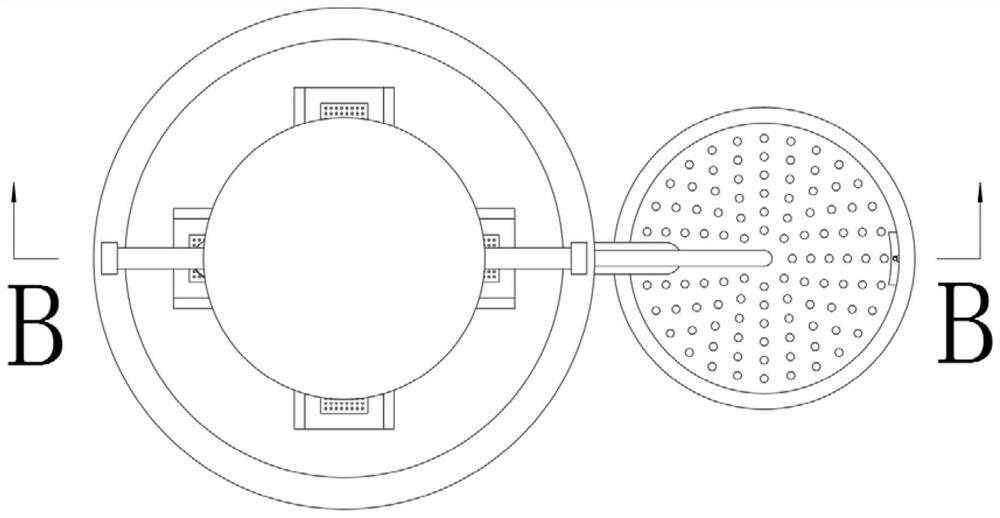

[0064] Such as Figure 1 to Figure 11 Shown, a kind of pulverizing device that is convenient to produce small molecule active selenopeptide, it comprises pulverizing tank 1, is provided with rotatable pulverizing disc 2 in described pulverizing tank 1, the outer wall of described pulverizing disc 2 and pulverizing tank 1 The inner walls are attached to each other, and a lifting plate 3 is slidingly arranged in the crushing pool 1 below the crushing plate 2. The lower end surface of the crushing plate 2 corresponds to the upper end surface of the lifting plate 3, and the lower end surface of the lifting plate 3 is provided with a cylinder 4. The cylinder 4 is arranged on the inner bottom surface of the crushing pool 1, the axis of the cylinder 4 is perpendicular to the inner bottom surface of the crushing pool 1, and the upper end surface of the crushing disc 2 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com