High-density flexible graphite bipolar plate as well as preparation method and application thereof

A flexible graphite, bipolar plate technology, applied in the direction of final product manufacturing, climate sustainability, sustainable manufacturing/processing, etc., can solve problems such as unsatisfactory mechanical strength and air tightness, and achieve a simple resin pretreatment method and reduce The effect of internal resistance, improving work efficiency and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

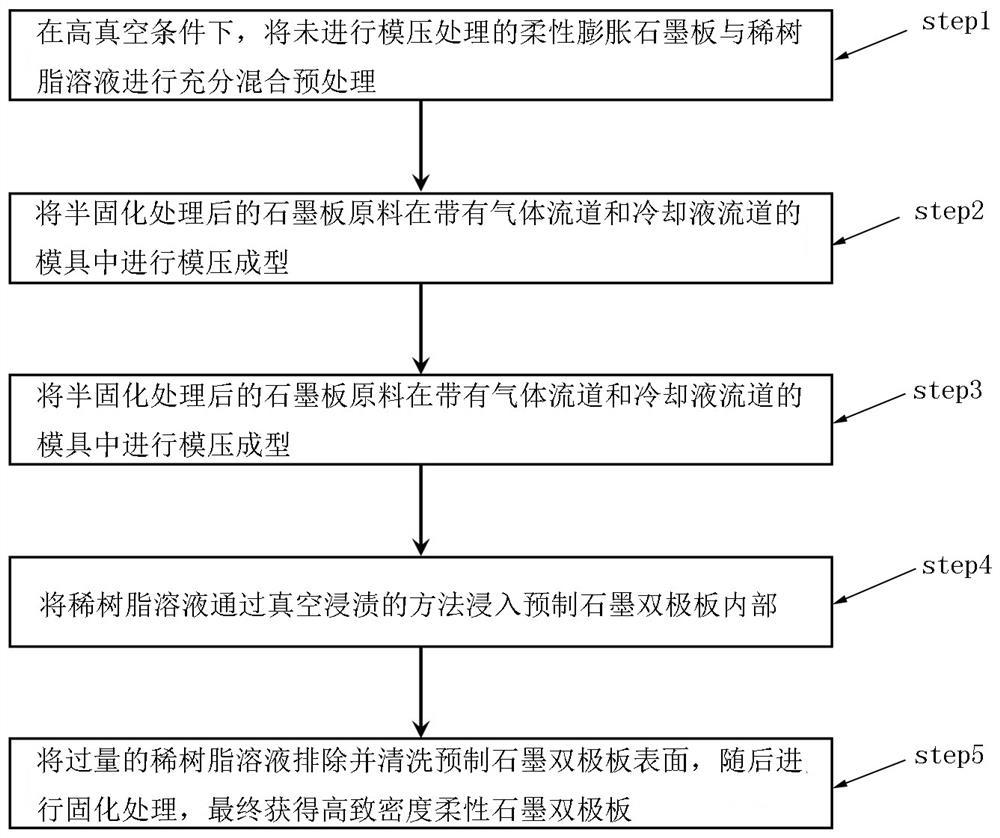

Method used

Image

Examples

Embodiment 1

[0041] A preparation method of a high-density flexible graphite bipolar plate is carried out according to the following steps.

[0042] 1) Set the density to 0.06g / cm 3 The flexible expanded graphite sheet is evenly mixed with the ethanol solution of epoxy resin with a solid content of 5%, and pre-impregnated for 30 minutes under a vacuum of -0.9 bar or higher; after the pre-impregnation, the surface resin is washed with room temperature water .

[0043] 2) Semi-curing the cleaned flexible expanded graphite sheet at 20°C for 20 min to obtain a graphite sheet raw material with certain flexibility.

[0044] 3) The above-mentioned graphite plate raw material is molded in a mold with a gas flow channel and a cooling liquid flow channel to obtain a density of 0.10g / cm 3 , Prefabricated graphite bipolar plates with a thickness of 5mm.

[0045] 4) Immerse the epoxy resin ethanol solution with a solid content of 5% into the interior of the prefabricated graphite bipolar plate by va...

Embodiment 2

[0048] A preparation method of a high-density flexible graphite bipolar plate is carried out according to the following steps.

[0049] 1) Set the density to 0.04g / cm 3 The flexible expanded graphite sheet is mixed evenly with a phenolic resin solution with a solid content of 7%, and pre-impregnated for 20 minutes under a vacuum of -0.9 bar or higher; after the pre-impregnation, the surface resin is washed with room temperature water. In this step, the solvent used in the phenolic resin solution is 50% methanol and 50% ethanol, calculated by volume.

[0050] 2) Semi-curing the cleaned flexible expanded graphite sheet at 15°C for 30 minutes to obtain a graphite sheet raw material with certain flexibility.

[0051] 3) The above-mentioned graphite plate raw material is molded in a mold with a gas flow channel and a cooling liquid flow channel to obtain a density of 0.08g / cm 3 , Prefabricated graphite bipolar plates with a thickness of 6mm.

[0052] 4) Immerse the phenolic resi...

Embodiment 3

[0055] A preparation method of a high-density flexible graphite bipolar plate is carried out according to the following steps.

[0056] 1) Set the density to 0.10g / cm 3 The flexible expanded graphite sheet is mixed evenly with a polyacrylic resin solution with a solid content of 8%, and pre-impregnated for 10 minutes under a vacuum of -0.9 bar or higher; after the pre-impregnation, the surface resin is washed with room temperature water. In this step, the solvent used in the polyacrylic acid resin solution is 30% methanol, 30% ethanol, 20% isopropanol, and 20% glycerol, calculated by volume.

[0057] 2) Semi-curing the cleaned flexible expanded graphite sheet at 25°C for 16 minutes to obtain a graphite sheet raw material with certain flexibility.

[0058] 3) The above-mentioned graphite plate raw material is molded in a mold with a gas flow channel and a cooling liquid flow channel to obtain a density of 0.15g / cm 3 , Prefabricated graphite bipolar plates with a thickness of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com