Antimicrobial modified sulfonated styrene-based polymer compound and preparation method thereof

A sulfonated styrene and anti-microbial technology, applied in coatings and other directions, can solve the problems of limited application, harsh functional reconstruction conditions, short-lived antibacterial activity, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0078] The present invention also provides a method for preparing the antimicrobial modified sulfonated styrene-based polymer compound described in the above technical solution, comprising the following steps:

[0079] a) neutralizing the sulfonated styrene-based polymer with an aqueous alkali metal hydroxide solution to obtain a neutralized sulfonated styrene-based polymer;

[0080] b) mixing the neutralized sulfonated styrene-based polymer with an aqueous solution of a cationic compound, and drying to obtain an antimicrobial modified sulfonated styrene-based polymer compound.

[0081] [About step a]:

[0082] a) Neutralizing the sulfonated styrene-based polymer with an aqueous alkali metal hydroxide solution to obtain a neutralized sulfonated styrene-based polymer.

[0083] Wherein, the sulfonated styrene-based polymer is consistent with that described in the previous technical solution, and will not be repeated here.

[0084] In the present invention, the alkali metal in ...

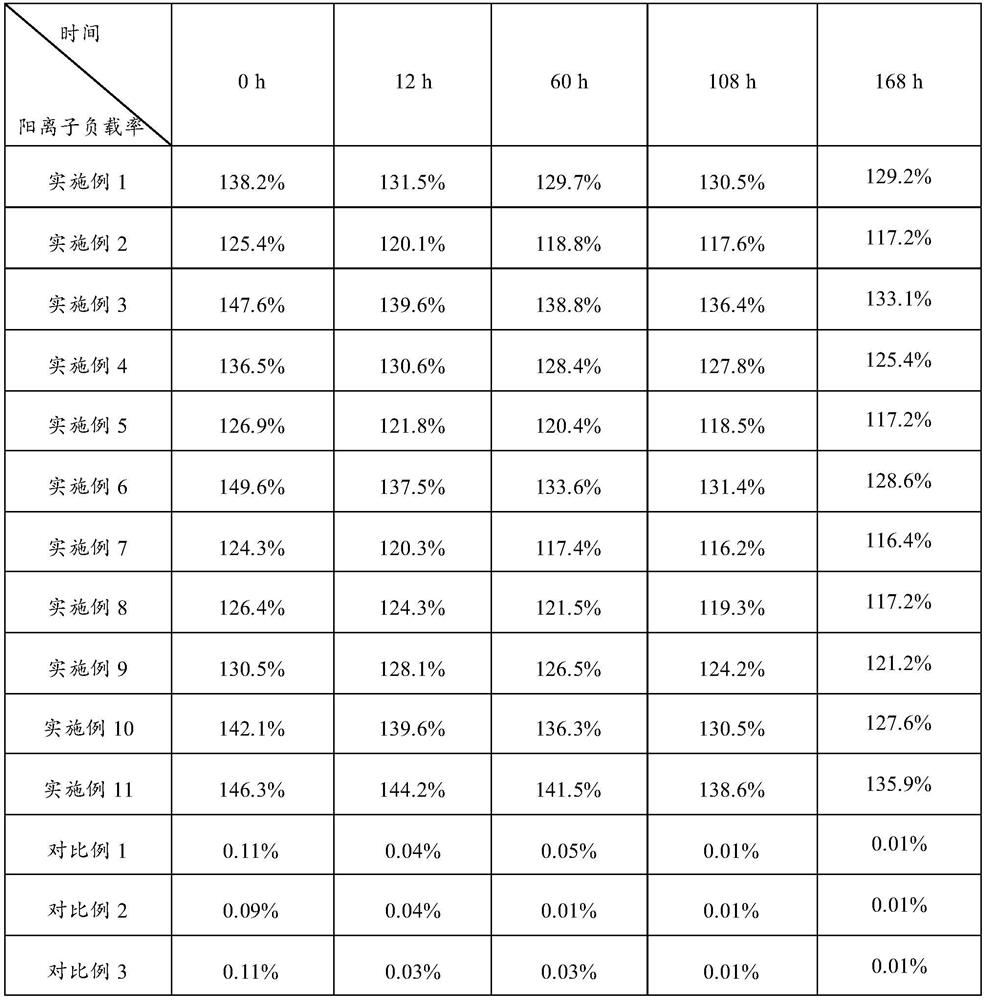

Embodiment 1

[0096] The sulfonated styrene-butadiene rubber polymer (the degree of sulfonation is 40 mol%, the content of styrene is 35wt%) is formed into a film to obtain the sulfonated styrene-butadiene rubber polymer film. Prepare a sodium hydroxide aqueous solution with a mass concentration of 1%, soak the sulfonated styrene-butadiene rubber polymer film in the above aqueous hydroxide solution for 24 hours, wash with water three times and dry at 50°C to obtain a neutralized sulfonated styrene-based polymer . Prepare an aqueous solution of benzalkonium chloride quaternary ammonium salt with a mass concentration of 1%, soak the neutralized sulfonated styrene-based polymer film in the aqueous solution of quaternary ammonium salt for 24 hours, wash with water three times and dry at 50°C for 8 hours to obtain an antimicrobial Modified sulfonated styrene-based polymer membrane (22.1% cationic compound content).

Embodiment 2

[0098] The sulfonated styrene-butadiene rubber polymer (the degree of sulfonation is 40 mol%, the content of styrene is 35wt%) is formed into a film to obtain the sulfonated styrene-butadiene rubber polymer film. Prepare a sodium hydroxide aqueous solution with a mass concentration of 1%, soak the sulfonated styrene-butadiene rubber polymer film in the above aqueous hydroxide solution for 24 hours, wash with water three times and dry at 50°C to obtain a neutralized sulfonated styrene-based polymer . Prepare a polyhexamethylene biguanide hydrochloride aqueous solution with a mass concentration of 1%, soak the neutralized sulfonated styrene-based polymer membrane in the above polyguanidine aqueous solution for 24 hours, wash with water three times and dry at 50°C for 8 hours to obtain Antimicrobially modified sulfonated styrene-based polymer membrane (25.4% cationic compound content).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com