500ml small-sized one-control multi-cell bioreactor

A bioreactor, multi-cell technology, applied in the field of experimental instruments, can solve the problems of easy mixing of impurities, affecting the accuracy of experiments, time-consuming and laborious, etc., to achieve the effect of eliminating transport, improving sealing, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following is attached Figure 1-6 The application is described in further detail.

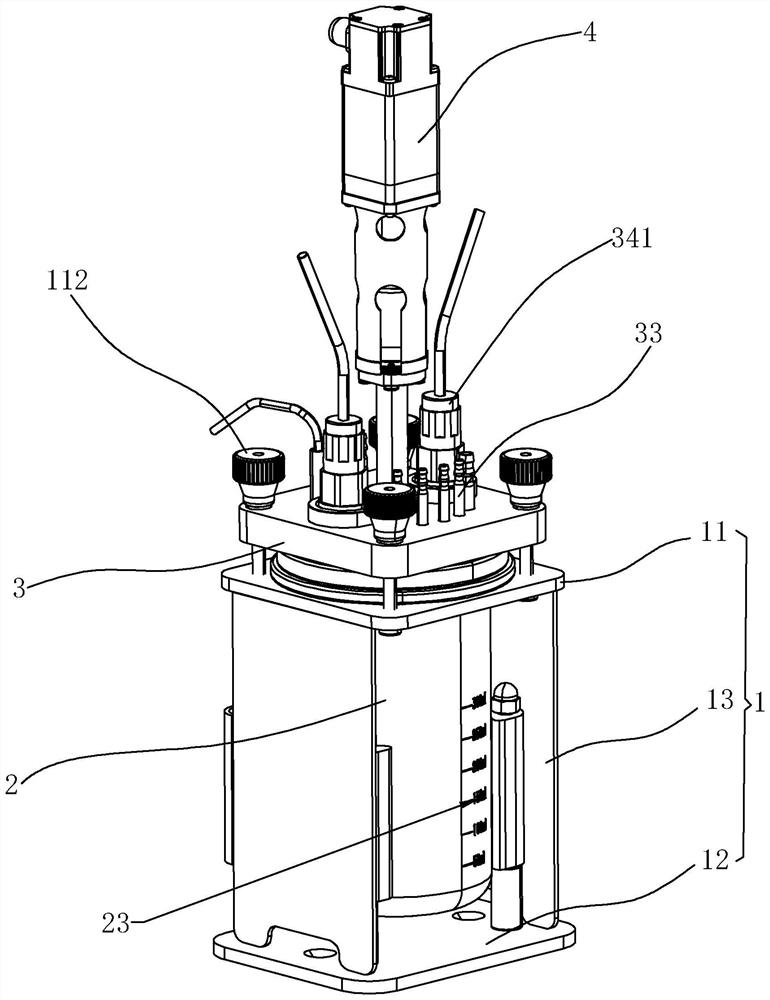

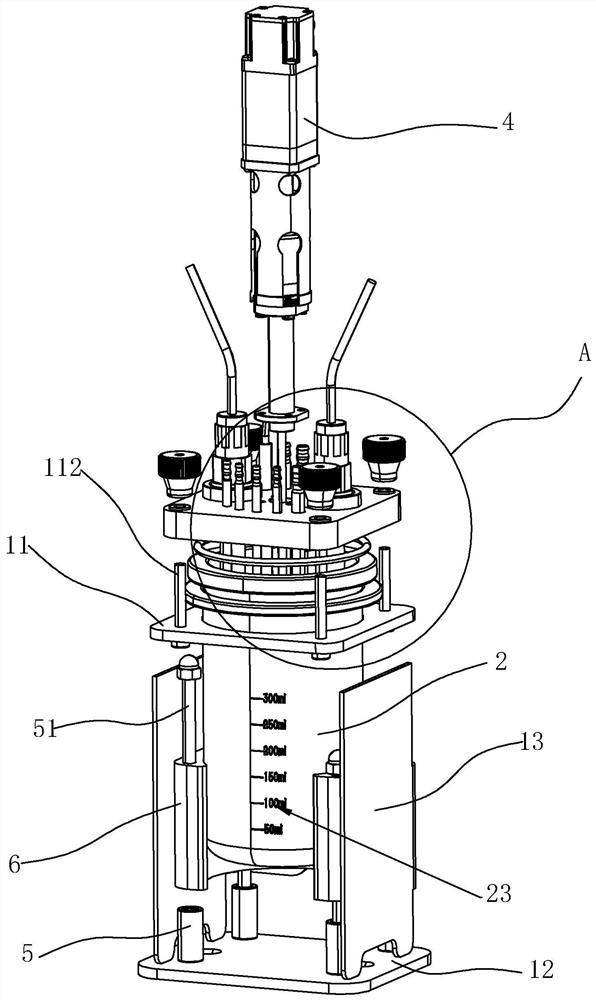

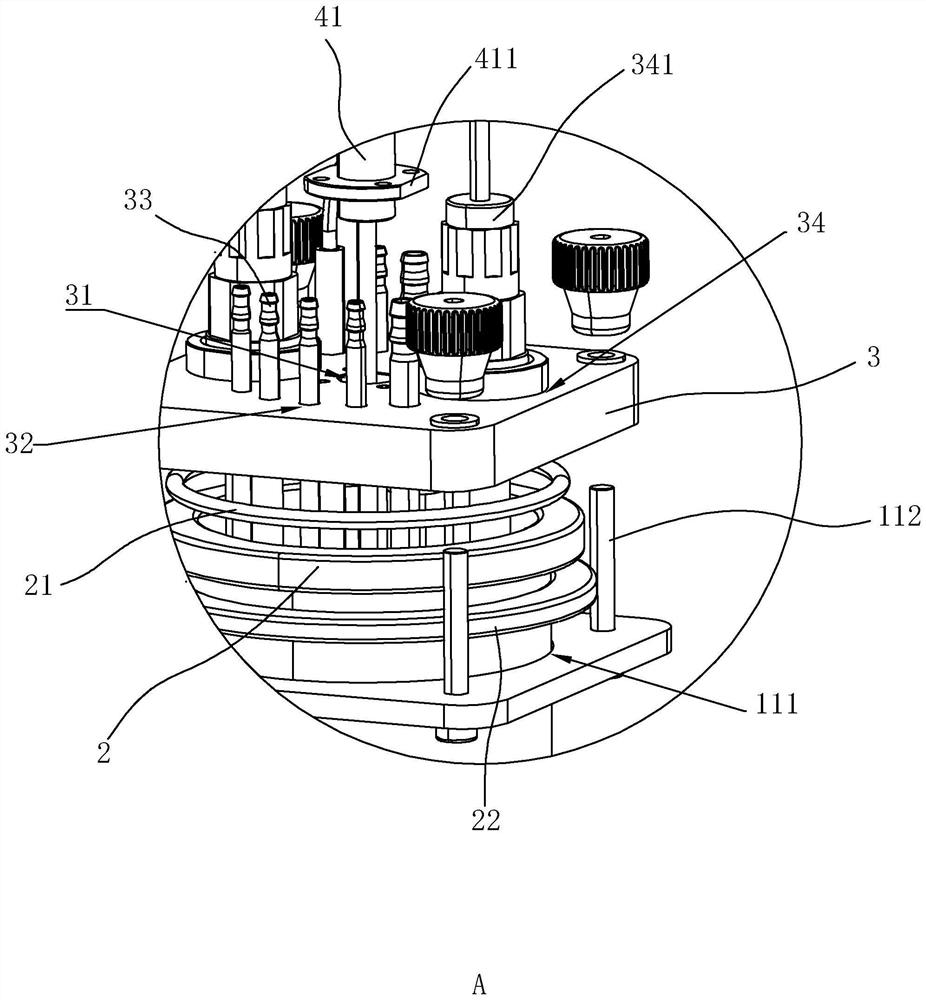

[0036] The embodiment of the present application discloses a 500ml small one-control multicellular bioreactor. refer to figure 1 and figure 2 , this application relates to a 500ml small one-control multicellular bioreactor. The specific structure includes a base 1 and a tank body 2 installed on the base 1. The base 1 includes a mounting plate 11 and a fixing seat assembly arranged in parallel up and down. 12. A round mouth 111 is opened through the mounting plate 11. The outer diameter of the cup opening at the upper end of the tank body 2 is larger than the diameter of the round mouth 111, and the tank body 2 and the round mouth 111 are plugged and matched; between the mounting plate 11 and the fixing seat assembly 12 There are two sets of support frames 13 distributed vertically and parallel in the opposite pull connection, and the four corners of the upper end surface of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com