Magnetic fluid sealing device

A magnetic fluid seal and sealing device technology, which is applied to engine seals, mechanical equipment, engine components, etc., can solve problems such as deformation of transmission structural parts, long equipment downtime, failure of magnetic fluid seals, etc., to reduce replacement and downtime The frequency of replacing spare parts and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

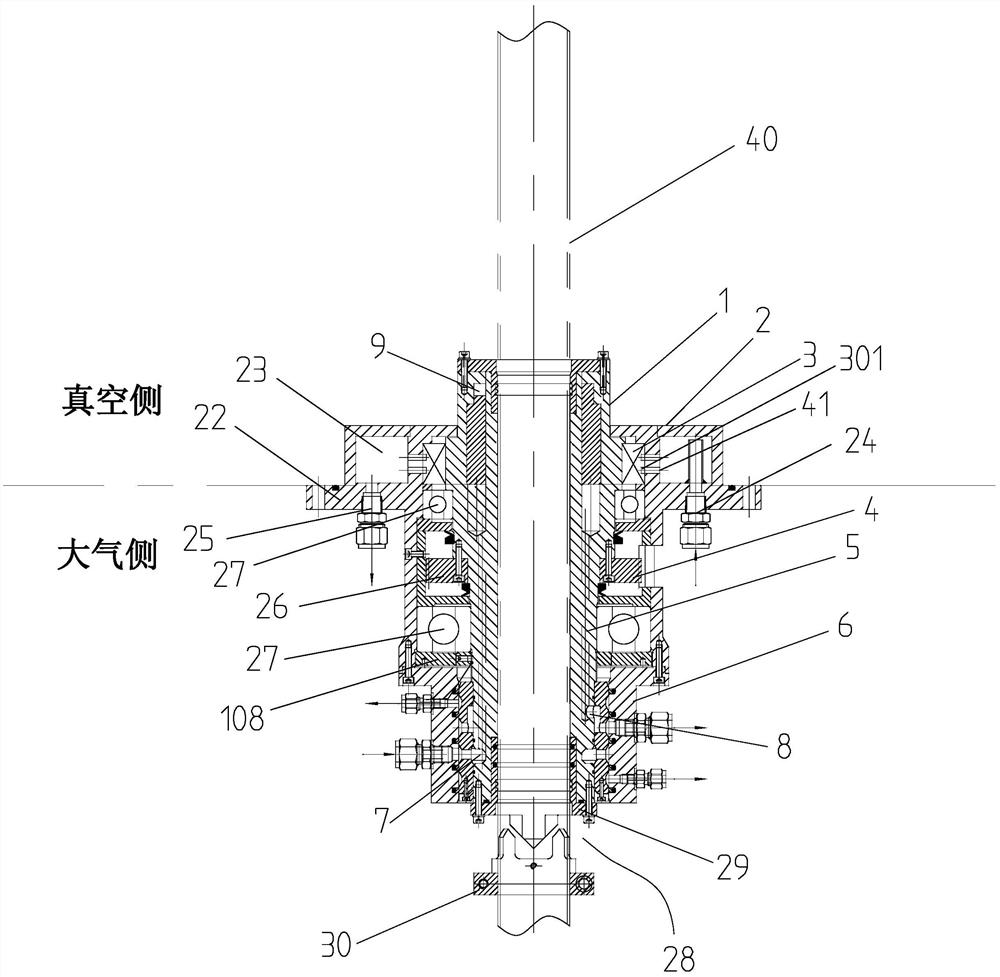

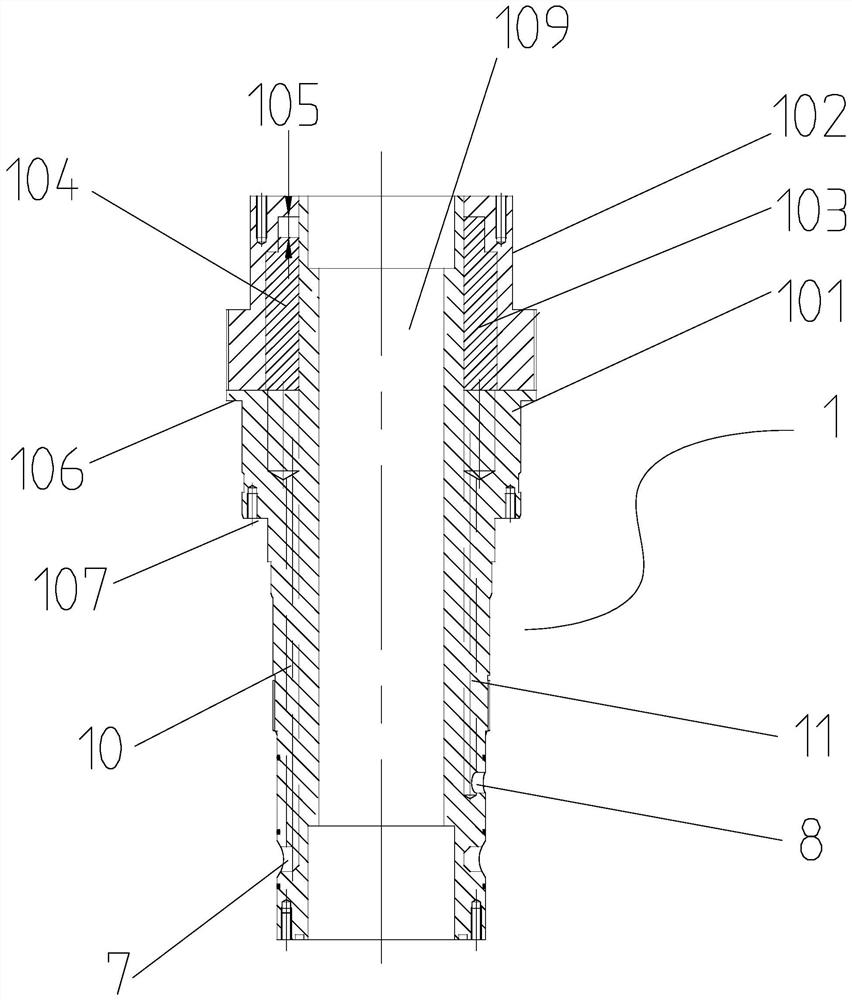

[0048] In the embodiment shown in Fig. 1, a magnetic fluid seal device includes a magnetic fluid seal assembly 3, the magnetic fluid seal assembly 3 is integrated on a body shaft 1, and the magnetic fluid seal assembly 3 below A transmission mechanism assembly 4 is integrated on the body shaft 1, a base 2 with a cooling structure is provided outside the magnetic fluid seal assembly 3 and the transmission mechanism assembly 4, and a body shaft 1 below the transmission mechanism assembly 4 is provided with Body shaft cooling seal assembly 6, said body shaft cooling seal assembly 6 communicates with the inside of the body shaft to form a body shaft cooling system. The body shaft cooling seal assembly 6 is arranged on the body shaft 1 below the base 2 and is in sealing contact with the base 2. The body shaft cooling seal assembly 6 communicates with the body shaft 1 to form a body shaft liquid cooling system.

[0049] The inside of the body shaft 1 is provided with a number of coo...

Embodiment 2

[0063] exist Figure 16 , Figure 17 In the shown embodiment, its technical solution is basically the same as that of Embodiment 1, except that: the body shaft cooling seal assembly 6 is arranged on the body shaft 1 inside the base 2 to form an integral sealing structure, and the The body shaft cooling seal assembly 6 communicates with the inside of the body shaft to form a gas cooling system for the body shaft.

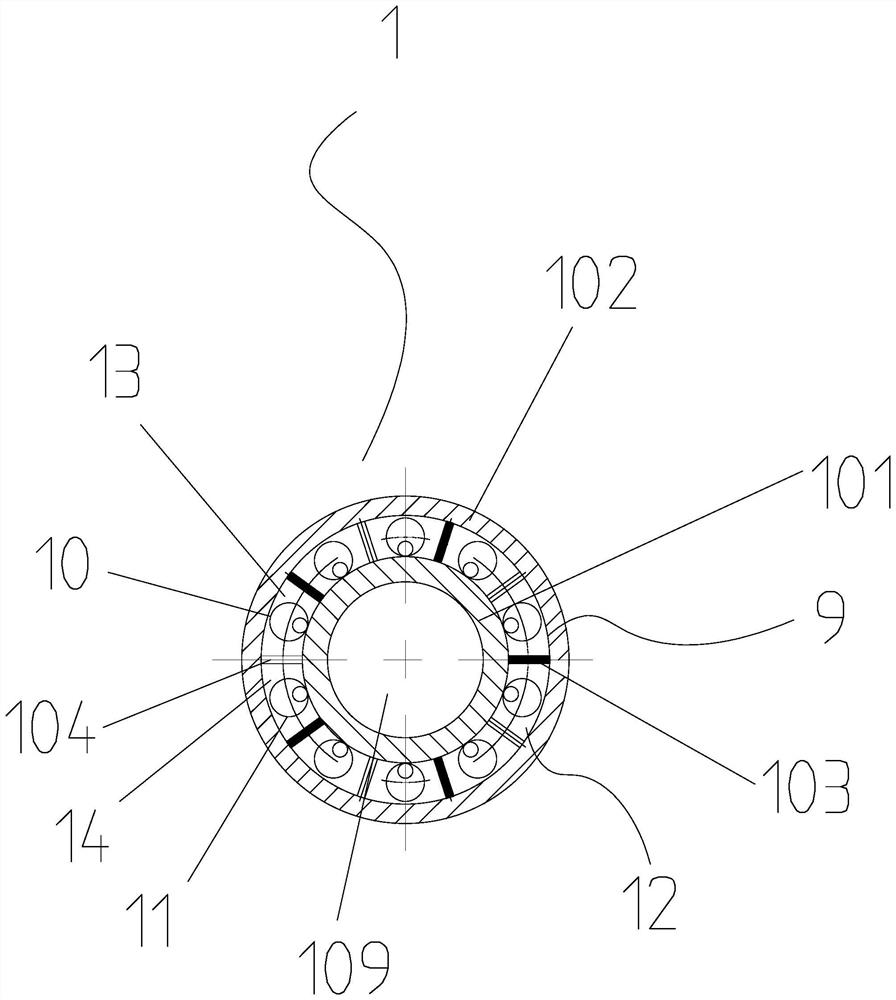

[0064] In this embodiment, the body shaft cooling seal assembly 6 includes a magnetic pole 1 6-1, a magnetic pole 2 6-2, a closed magnetic block structure and a magnetic pole locking gland 6-5; the magnetic pole 1 6-1 and The second magnetic pole 6-2 is respectively sleeved on the main body shaft 1 from top to bottom and is dynamically sealed with the main body shaft 1 through a closed magnetic field structure. The inner wall of the static sealing fit; such as Figure 18 As shown, in this embodiment, two sealing grooves 6-9 are respectively arranged on the outer d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com