Transition tube for gas turbine can combustor

A gas turbine and transition pipe technology, which is applied in gas turbine installations, combustion chambers, combustion equipment, etc., can solve problems such as affecting structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041]In conjunction with the accompanying drawings, the technical content and detailed description of the present invention are hereinafter described according to preferred embodiments, and are not intended to limit the implementation scope thereof. Any equivalent changes and modifications made in accordance with the appended claims are all covered by the claimed invention.

[0042] The present invention will now be described in detail with reference to the accompanying drawings.

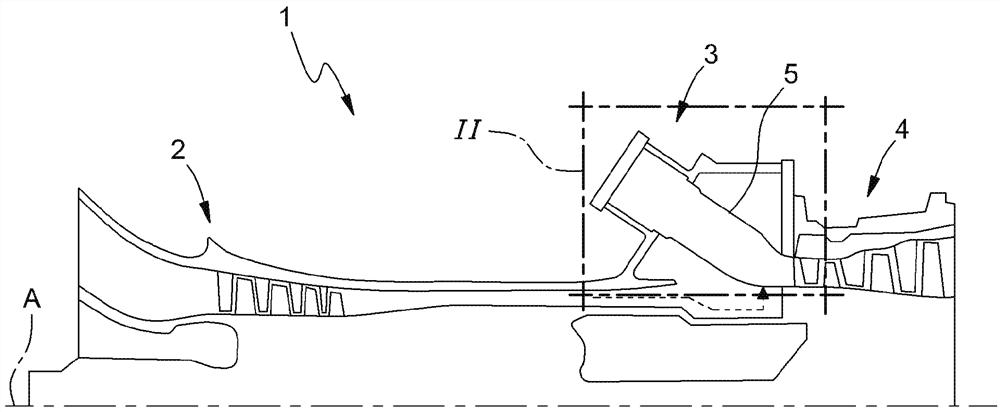

[0043] see figure 1 , figure 1 is a side elevation view of a gas turbine assembly, which may be provided with a plurality of transition ducts according to the present invention, taken along an axial longitudinal plane. in particular, figure 1 A simplified view of a gas turbine assembly generally indicated at 1 is disclosed. Gas turbine assembly 1 includes a compressor 2 , a combustor assembly 3 and a turbine 4 . The compressor 2 and the turbine 4 extend along a main axis A. figure 1 The burne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com