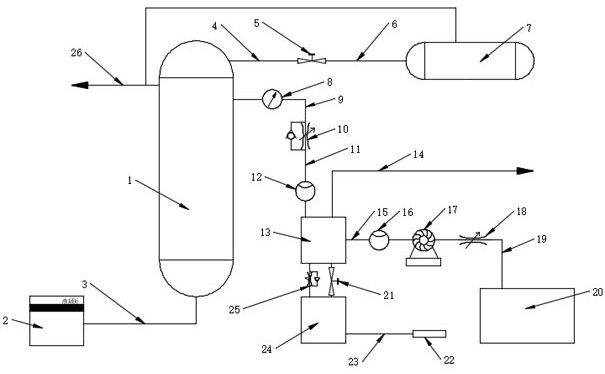

Condensate acid discharge device of two-in-one graphite synthesis furnace

A technology of graphite synthesis furnace and discharge device, which is applied in the direction of feeding device, climate sustainability, chlorine/hydrogen chloride, etc., and can solve the problems of irreversible damage to the furnace bottom of the synthesis furnace, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

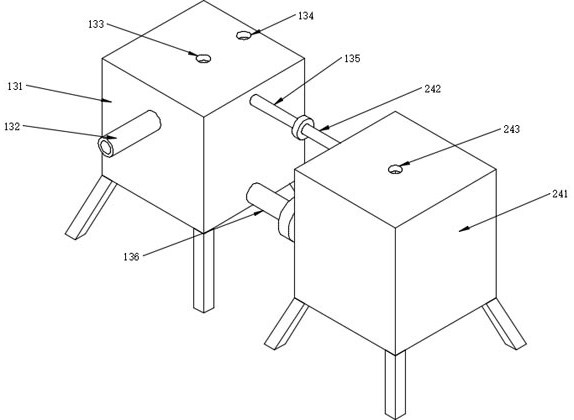

Embodiment 1

[0020] Further, the liquid seal assembly includes a pipeline one 3 and a liquid seal box 2, one end of the pipeline one 3 is inserted into the bottom of the synthesis furnace body 1, and the other end of the pipeline one 3 is inserted into the bottom end of the outer side wall of the liquid seal box 2, The top of the liquid-sealing box 2 is open, and water is placed inside the liquid-sealing box 2. The liquid-sealing box 2 cannot be higher than the bottom of the synthesis furnace body 1, so that the water in the liquid-sealing box 2 can be prevented from entering the synthesis furnace body 1, and the synthesis The flame in the furnace body 1 will emerge from the furnace bottom, and at this time, it will be blocked by the water in the liquid sealing box 2, so as to prevent the flame from leaking out.

[0021] Further, the hydrogen chloride buffer assembly comprises a pressure regulating valve one 5 and a hydrogen chloride buffer tank 7, and the input end and the output end of th...

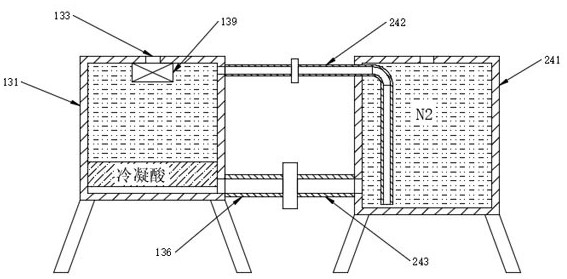

Embodiment 2

Based on the discharge device for condensing acid of a two-in-one graphite synthesis furnace provided in the first embodiment of the present application, the second embodiment of the present application proposes another discharge device for condensing acid of a two-in-one graphite synthesis furnace. The second embodiment is only a further form of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0028] Attached below Figure 7 The second embodiment of the present invention will be further described with the embodiment: the pipeline system three, the nitrogen tank 20 and the pressure regulating valve-5 are removed, the hydrogen chloride buffer tank 7 is communicated with the exhaust end of the synthesis furnace body 1 through the pipeline, and the exhaust pipe 26 is communicated with the hydrogen chloride buffer tank 7, and a pressure balance pipe 27 for connecting the two is provided b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap