Full-automatic lens centering edge grinding machine

A kind of edging machine, fully automatic technology, applied in the direction of machine tools suitable for grinding the edge of workpieces, parts of grinding machine tools, grinding machines, etc., can solve the problems of affecting the effect of lens edging, low precision, and unguaranteed yield rate, etc. Achieve the effects of improving convenience and automation efficiency, high yield and production efficiency, and improving surface processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

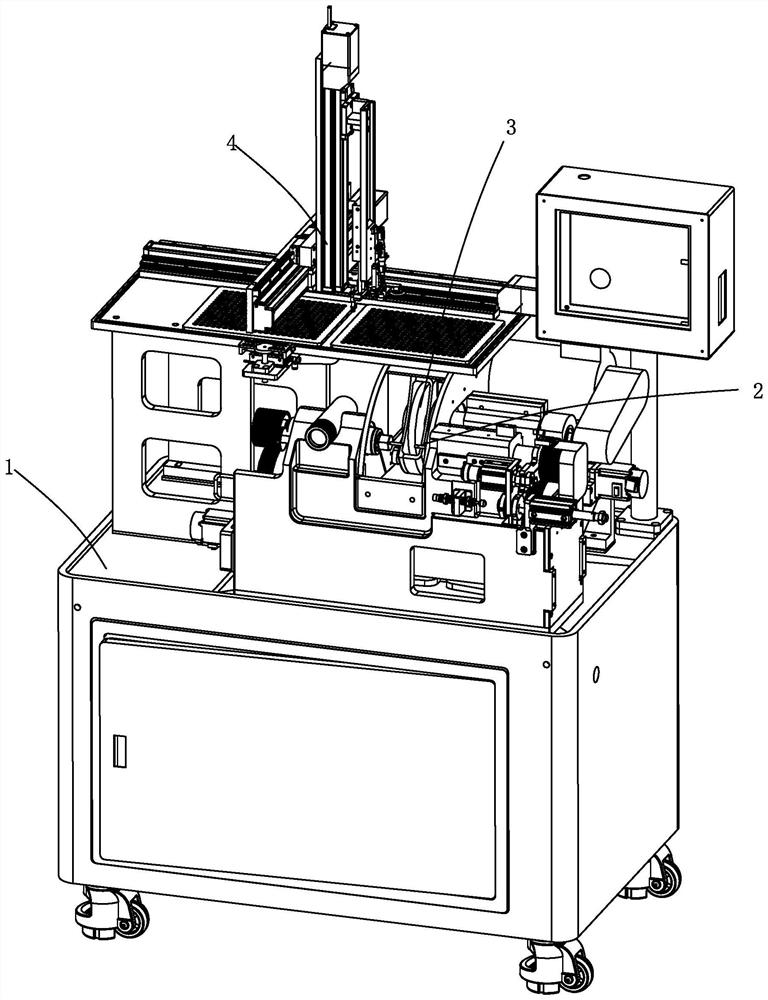

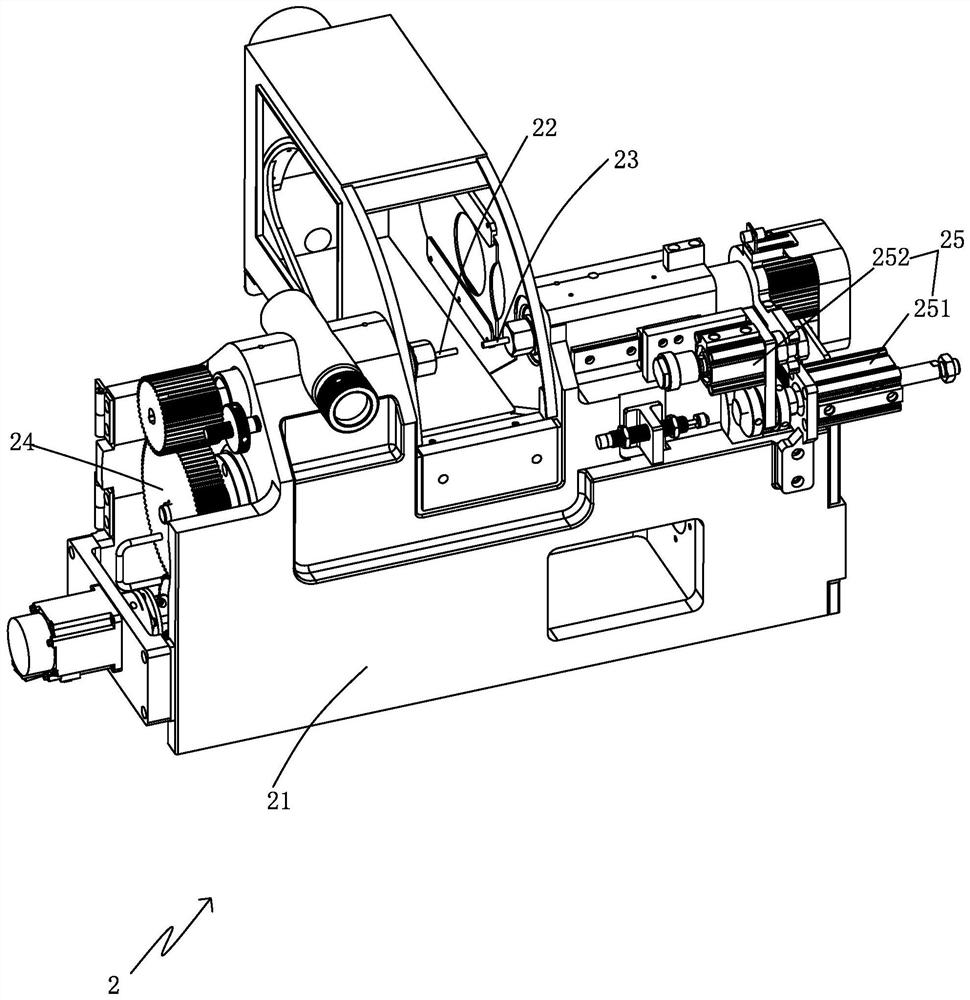

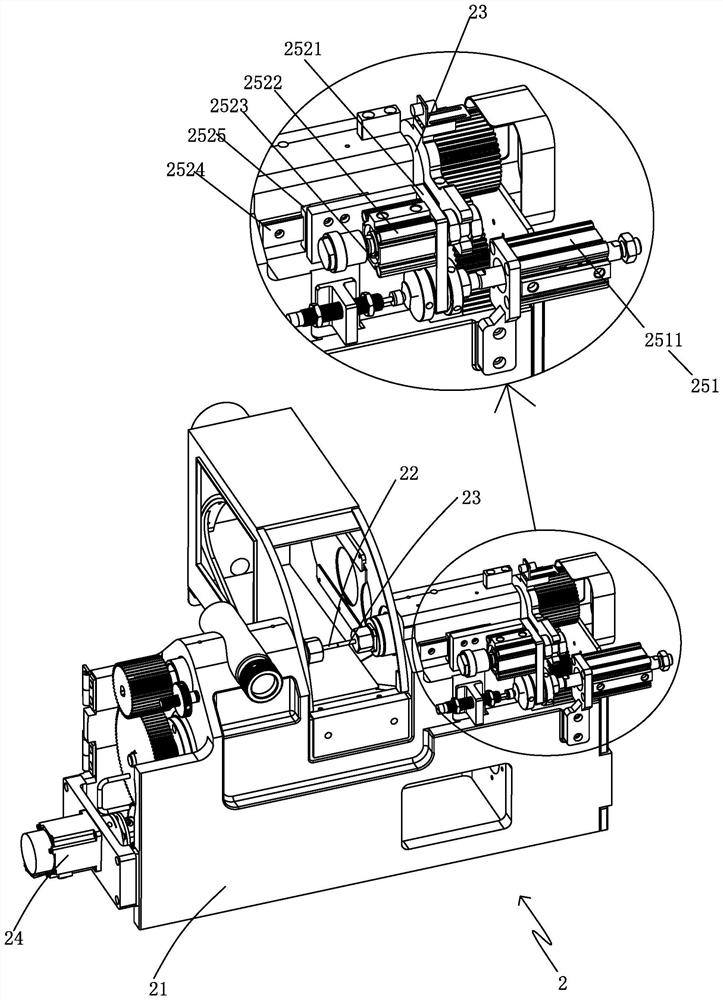

[0054] like Figure 1-12 As shown, the automatic lens centering and edging machine includes a body 1, and the body 1 is provided with a clamping device 2, an edging device 3 and a feeding device 4;

[0055] The present application provides an automatic lens centering and edging machine, which includes a body, a clamping device, an edging device and a feeding device. The feeding device automatically corrects and moves the lens to be processed to the clamping device for feeding, and the clamping device The lens to be processed is first adsorbed and then clamped, and then the clamping shaft rotates synchronously, relying on centrifugal force and clamping force to automatically align the lens to the center, and then the edging device moves horizontally relative to the lens to perform multi-directional precise edging processing. The device takes out and unloads the lens from the clamping device, and the present application has a simple structure, improves the convenience and automa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com