High-durability polypropylene sound insulation material and preparation method thereof

A technology of durable polypropylene and sound insulation materials, applied in the directions of plant fibers, fiber processing, textiles and paper making, etc., can solve the problem that the sound insulation cannot meet the requirements and so on

Inactive Publication Date: 2022-06-03

常州精瑞斯新材料科技有限公司

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

(1) Soak the hemp fiber in the ammonium polyphosphate solution. After it is completely soaked, take the hemp fiber out of the ammonium polyphosphate solution and let it stand in the air. length, add intumescent flame retardant system to polypropylene to obtain flame retardant polypropylene, mix the flame retardant polypropylene with the sheared hemp fiber in step S1 evenly, add iron powder, antioxidant, lubricant and compatibilizer The high-durability polypropylene sound insulation material is obtained by blending and masticating, which solves the problem that the sound insulation of existing polypropylene materials cannot meet the requirements;

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

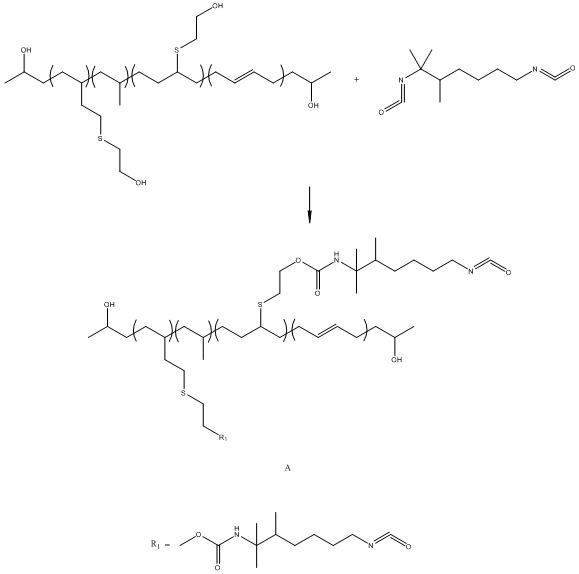

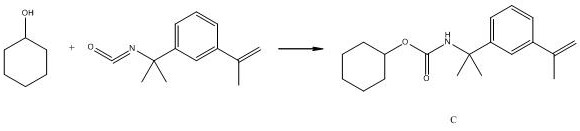

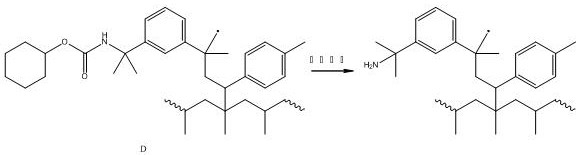

[0016] Antioxidants are prepared by the following steps:

Embodiment 2

[0018] Antioxidants are prepared by the following steps:

Embodiment 3

[0020] Antioxidants are prepared by the following steps:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a high-durability polypropylene sound insulation material and a preparation method thereof, and relates to the field of polypropylene sound insulation materials.The preparation method comprises the steps that fibrilia is soaked in an ammonium polyphosphate solution, dried and sheared, an intumescent flame-retardant system is added into polypropylene, flame-retardant polypropylene and the sheared fibrilia are evenly mixed, and the high-durability polypropylene sound insulation material is obtained; the high-durability polypropylene sound insulation material is obtained by adding iron powder, an antioxidant, a lubricant and a compatilizer and blending and plastifying, and the problem that the sound insulation property of an existing polypropylene material cannot meet the requirement is solved; the flame-retardant system is added to carry out flame retardance on the polypropylene matrix, the iron powder is added to add inertia load, the sound insulation performance of polypropylene is improved, the fibrilia has good sound absorption and sound insulation performance according to the Huygens principle, when a sound source exists, most sound waves are reflected, and the sound insulation performance is improved. When entering the polypropylene composite material, a small part of the material interacts with a large number of interpenetrating microporous structures from the outside to the inside to realize an absorption process, so that the purpose of enhancing the sound insulation effect is achieved.

Description

technical field [0001] The invention relates to the field of polypropylene soundproofing materials, in particular to a high-durability polypropylene soundproofing material and a preparation method thereof. Background technique [0002] Sound insulation materials refer to a class of materials, components or structures that can block sound transmission or weaken transmitted sound energy, and are characterized by heavier mass and higher density, such as steel plates, aluminum plates, concrete walls, brick walls, etc. As a general rule, the heavier the material, the better the sound insulation; Compared with epoxy resin and oxyester thermosetting sound insulation materials, thermoplastic polypropylene has the processing convenience and timeliness of integral injection molding, thermoplastic polypropylene composite material is recyclable, economical and circular, and has excellent mechanical properties and Processing performance, heat resistance, low price, occupy an important ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L23/12C08L1/02C08L75/14C08L51/06C08K3/08C08K5/053C08K5/3492C08K3/32D06M11/72C08G18/69C08G18/73C08G18/32C08F255/02C08F212/32D06M101/06

CPCC08L23/12D06M11/72C08G18/696C08G18/73C08G18/387C08F255/02C08L2205/16C08K2003/0856C08K2003/323D06M2101/06C08L2205/08C08L2201/02C08L2201/08C08L1/02C08L75/14C08L51/06C08K3/08C08K5/053C08K5/34922C08K3/32C08F212/32

Inventor 敬小园郐羽

Owner 常州精瑞斯新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com