Multi-parameter adjustable jet flow and pipe flow combined gas-liquid-solid erosive wear experimental device and use method thereof

An experimental device and multi-parameter technology, applied in measuring devices, testing wear resistance, instruments, etc., can solve the problems of rarely considering the impact of temperature on material erosion, and the erosion angle can be adjusted. The method is simple and convenient, the performance is stable, and the operation performance is strong.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

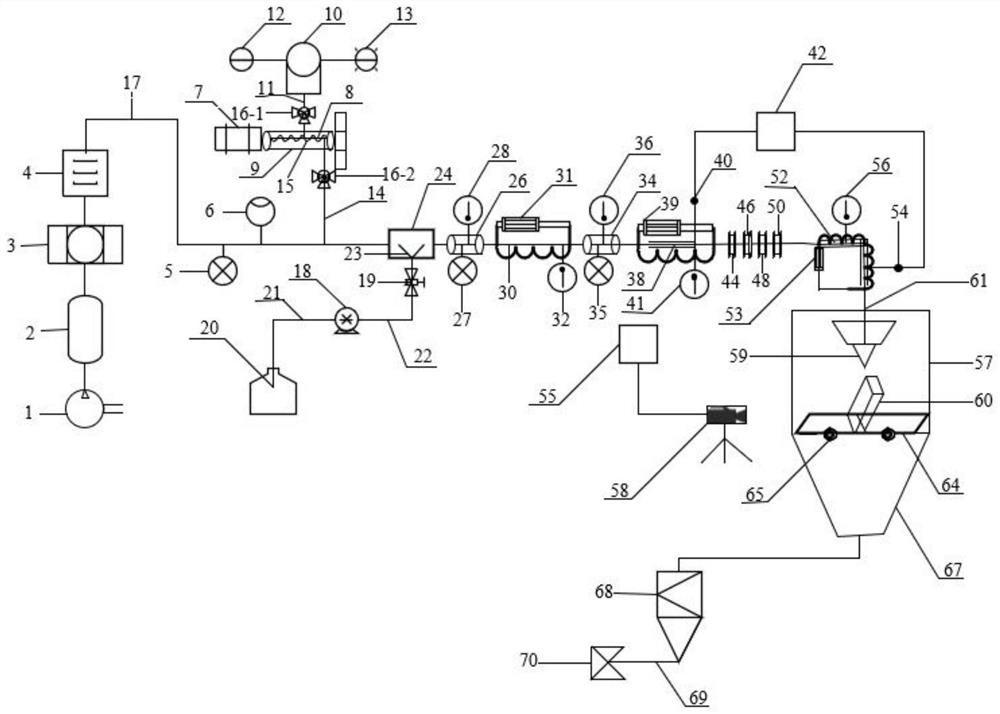

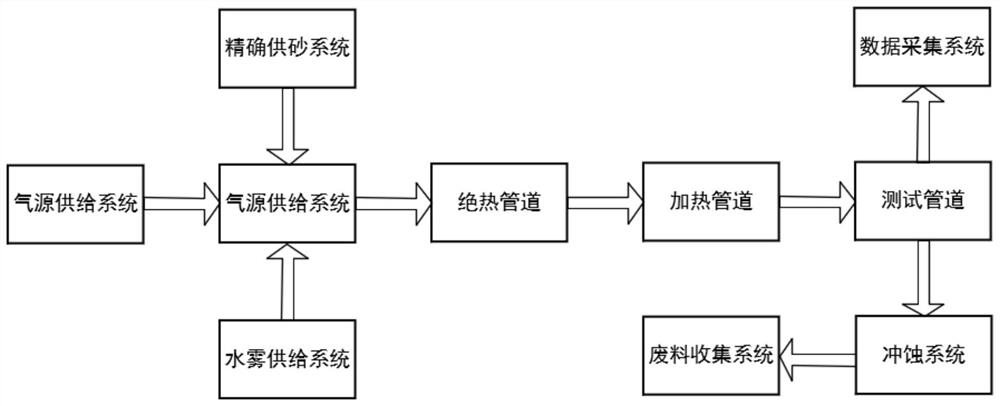

[0048] like figure 1 , figure 2 As shown, the present invention provides a gas-liquid-solid erosion wear experimental device combining multi-parameter adjustable jet flow and pipe flow, including the following:

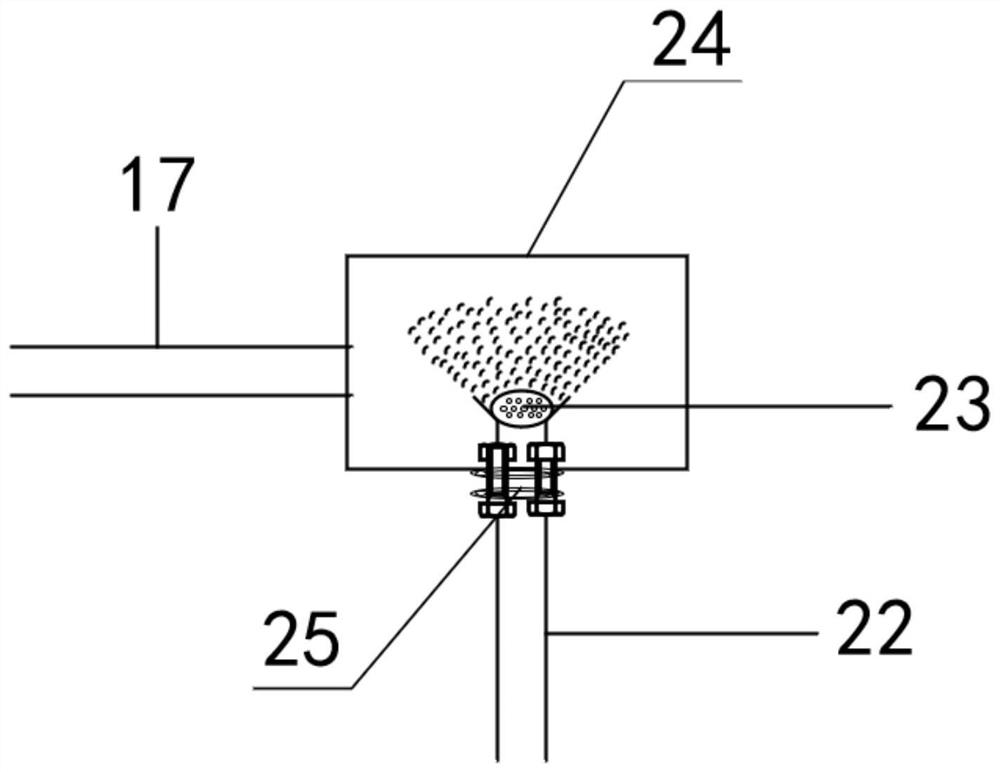

[0049] A buffer tank 2 is connected to the outlet of the air compressor 1, a filter 3 is connected to the outlet of the buffer tank 2, and an air dryer 4 is connected to the outlet of the filter 3. Compressed to the corresponding pressure, the filter 3 can filter the high-pressure gas flowing out of the buffer tank 2 to eliminate impurities in the high-pressure gas, and the air dryer can dry the high-pressure gas flowing out of the filter 3 to eliminate the humidity contained in the high-pressure gas Influence on the accurate water supply of the metering pump, the pressure sensor 5 and the flow meter 6 are installed in the pipeline of the outflow section of the dryer to realize the measurement of the fluid pressure and fluid velocity parameters in the gathering pipe...

Embodiment 2

[0062] A gas-liquid-solid erosion wear experimental device combining multi-parameter adjustable jet and pipe flow, the structure is as described in Example 1, the difference is that as Figure 5 , Figure 7 , Figure 8 As shown, the base is fixed on the metal sand control net 64 through the flange 71, which is convenient to adjust the relative position of the nozzle 59 and the sample 60. The vise 65 includes two clamp blocks 72 to fix and disassemble the sample, in order to move The clamp block and the fixed clamp block, an angle ruler 66 is fixed on the fixed clamp block, and the clamping angle of the sample can be changed with reference to the angle ruler during the experiment, so as to control the erosion angle.

Embodiment 3

[0064] A gas-liquid-solid erosion wear experiment device combining multi-parameter adjustable jet and tube flow, the structure is as described in Example 1, the difference is that the multi-parameter adjustable jet and tube flow combined gas-liquid The solid erosion wear experimental device also includes a waste collection system. The waste collection system includes an upside-down regular quadrangular platform 67, a cyclone separator 68, and a collection device 70. The bottom of the splash-proof chamber is a metal sand-proof mesh. The prismatic platform 67 is welded and connected, and the top of the upside-down square prismatic platform 67 is welded with a collection pipe 69 matching the inlet size of the cyclone separator 68. The cyclone separator 68 separates and buffers the inflowing mixed fluid, and the cyclone separator 68 The outlet of the cyclone is connected to the collecting device 70, and the collecting device 70 can collect and process the mixture processed by the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com