One-fire and one-time billeting die and method for alloy bar material and method for upsetting, extrusion and large deformation

A technology for alloy rods and molds, which is applied in the field of upsetting, extrusion, large deformation, and one-shot blanking molds for alloy rods. It can solve the problems of many alloy processing passes, poor deformation uniformity, high equipment requirements and high energy consumption, and achieve Increase strain, prevent metal outflow, and improve the effect of microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The specific embodiments of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments. The following examples are intended to illustrate the present invention, but not to limit the scope of the present invention.

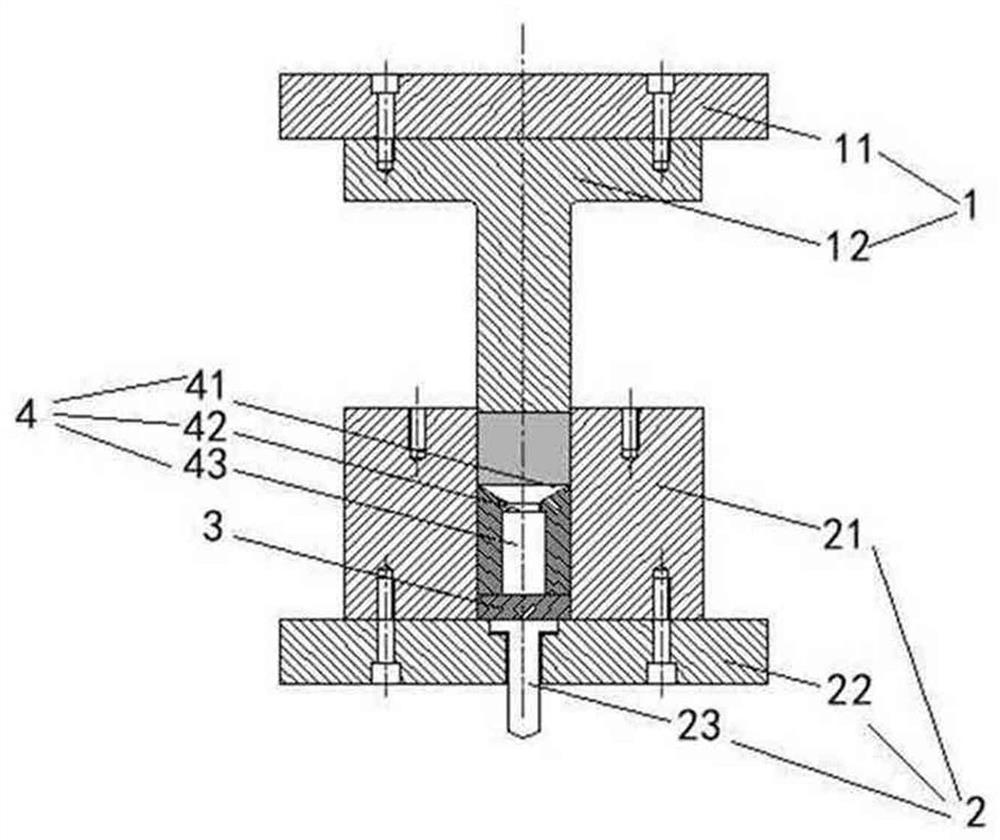

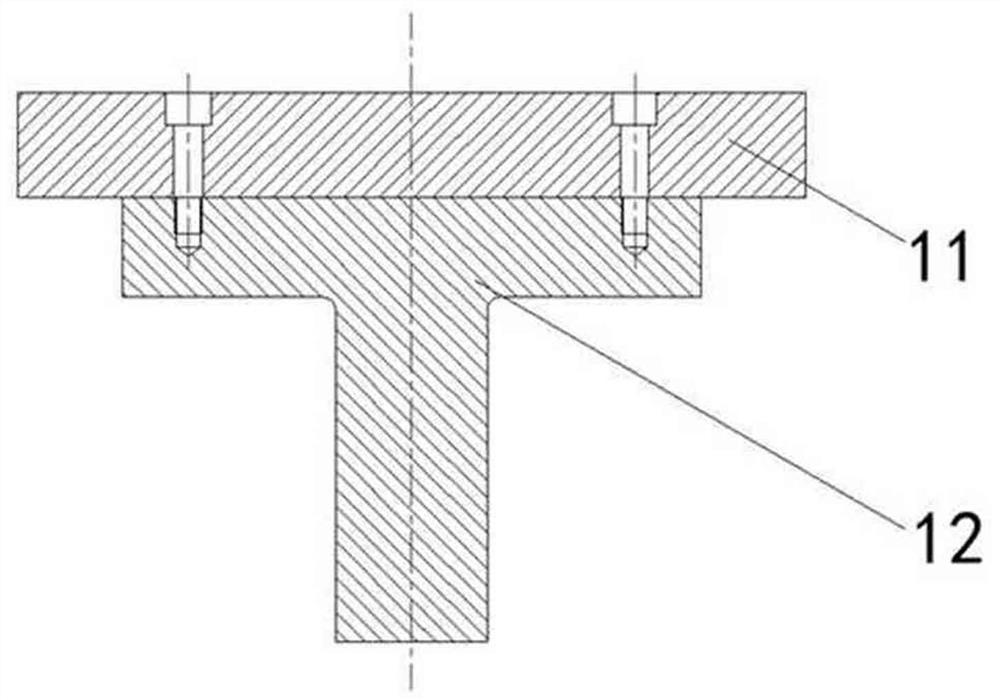

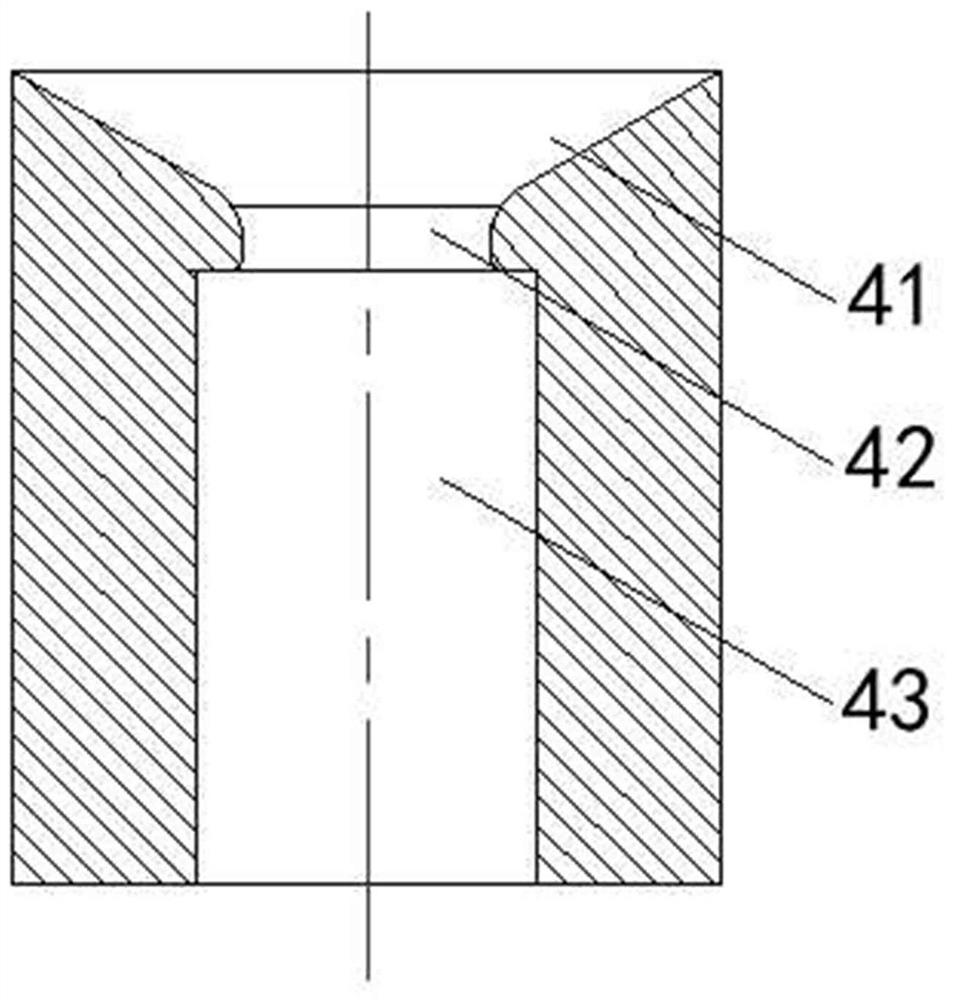

[0041] like Figure 1 to Figure 3 As shown, the present invention provides a primary blanking die for an alloy bar, which includes a first die assembly 1 and an upsetting die 4; the cavity of the upsetting die 4 includes an upper cavity segment that communicates in sequence 41. The middle cavity section 42 and the lower cavity section 43, the inner cavity shape of the upper cavity section 41 is an inverted conical boss, the inner cavity shape of the middle cavity section 42 and the lower cavity section 43 are cylindrical, and the upper cavity shape is cylindrical. The cavity section 41 smoothly transitions to the middle cavity section 42, and there is a difference in cross-sectional area at th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com