Laser welding device for multi-layer current collector and outer tab

A technology of laser welding and laser welding head, applied in laser welding equipment, welding equipment, welding equipment, etc., can solve the problems of current collector damage, tab connection failure, welding failure, etc., to reduce equipment development costs and simplify welding process. , The effect of stable welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the above objects, features and advantages of the present invention more clearly understood, the present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

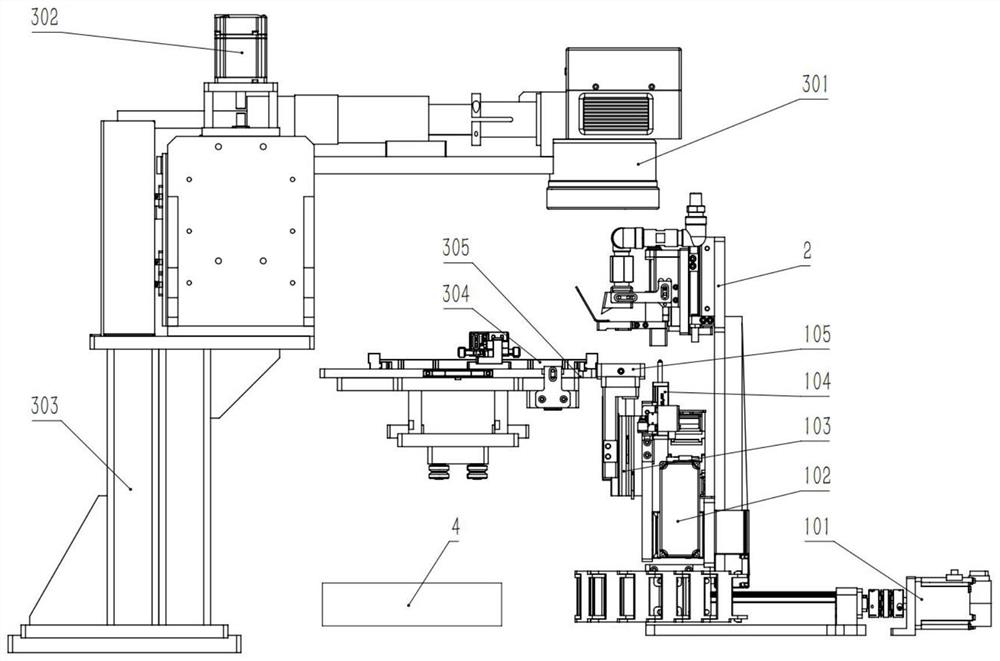

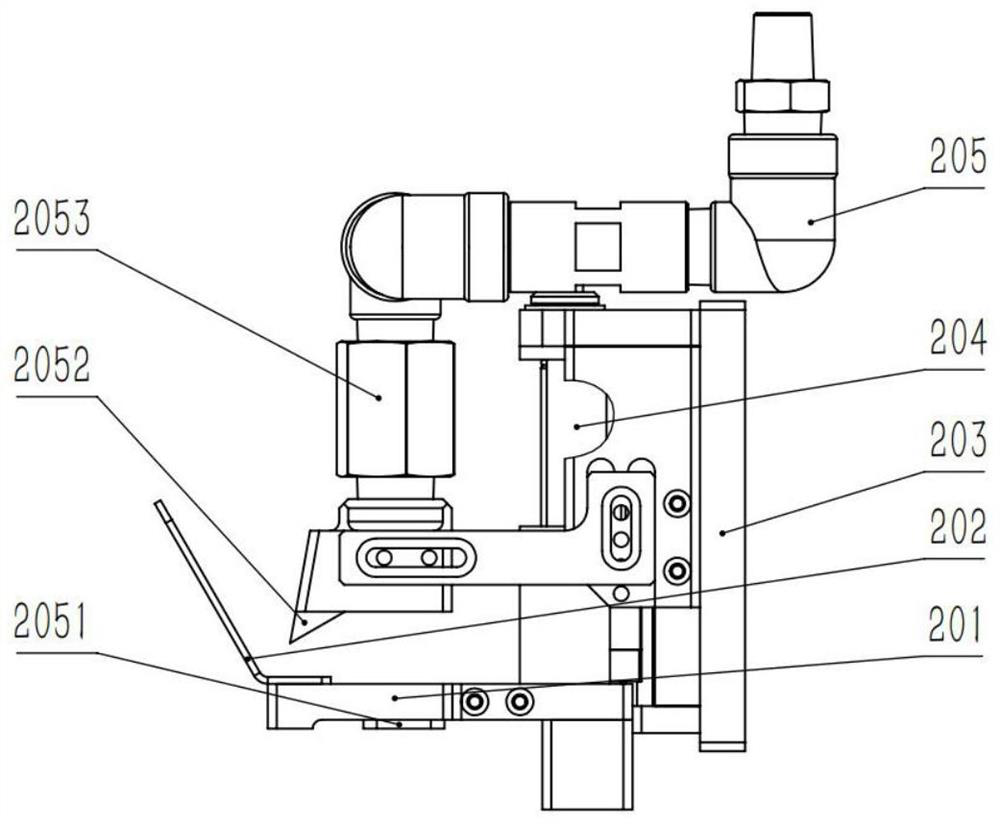

[0033] like figure 1 and figure 2 As shown in the figure, a laser welding device for multilayer current collectors and outer tabs mainly includes an outer tab feeding and moving platform, a tab pressing and dust collection mechanism 2, a welding head and a battery cell placement platform, and a PLC central control system 4. The other three institutions communicate with the PLC central control system 4 through a circuit / network connection, and the PLC receives signals and issues commands uniformly.

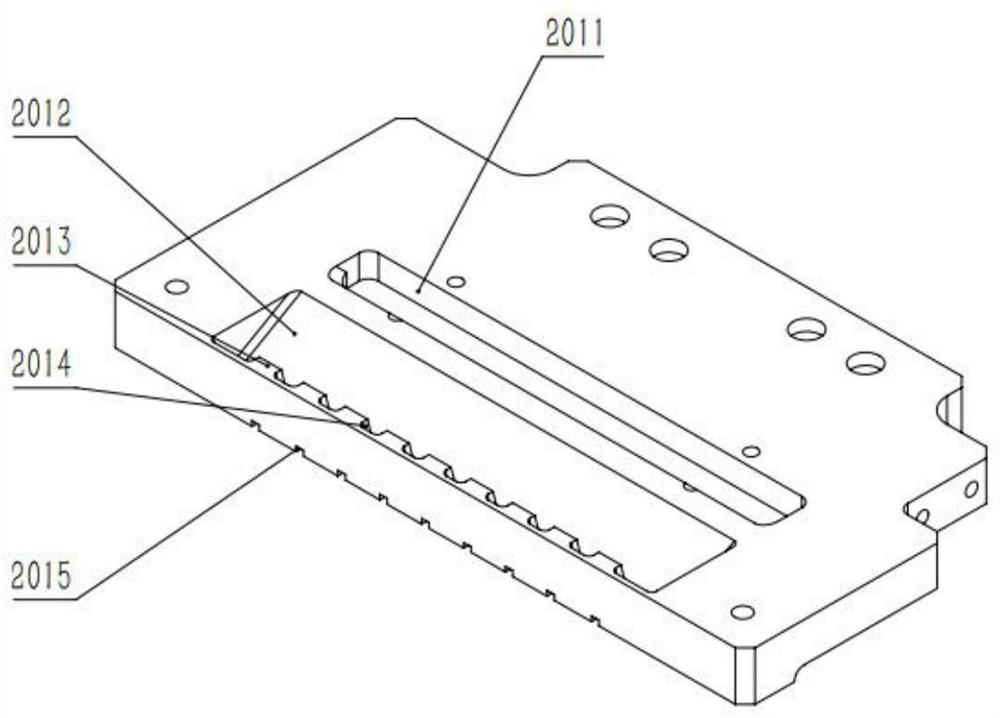

[0034] The outer tab feeding mobile platform includes a Y-axis moving module 101 , an X-axis moving module 102 , a telescopic cylinder 1 103 , a precision displacement sensor 104 and a negative pressure welding table 105 . The ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com