Indoor sludge solidification method based on skeleton structure

A skeleton structure and solidification method technology, applied in the direction of solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problems of narrow application area, non-proportional input and output, etc., and achieve overall strength improvement, low price, The effect of reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

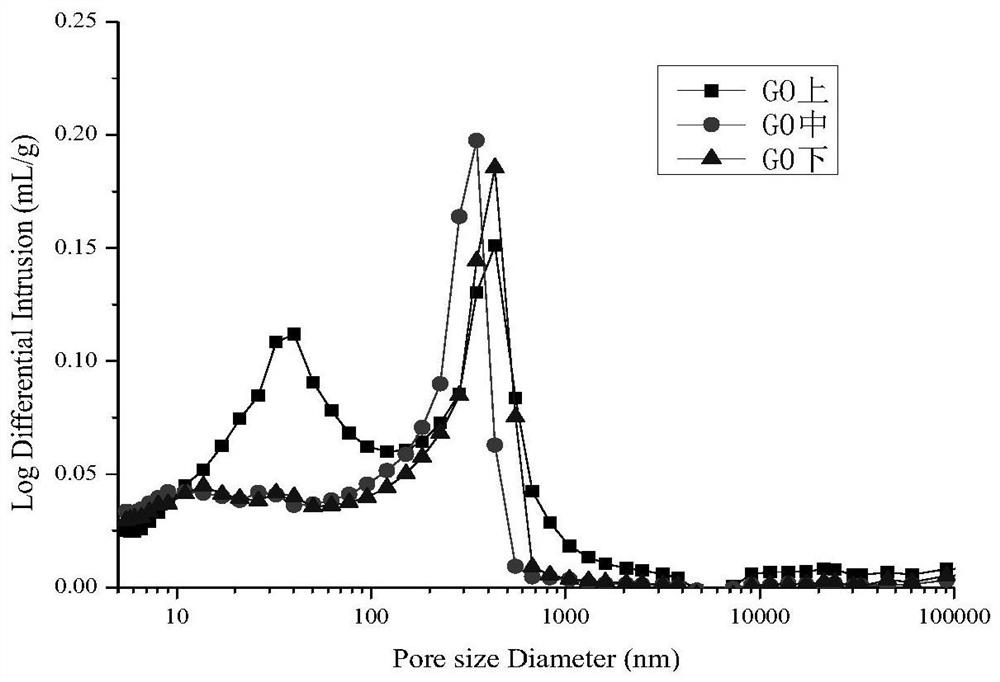

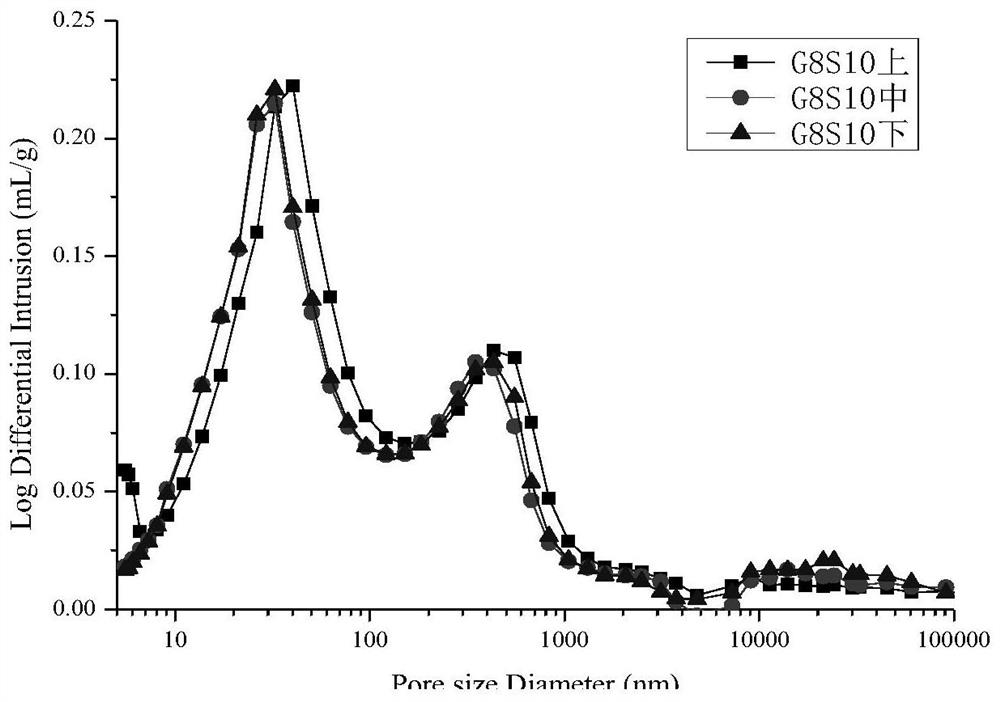

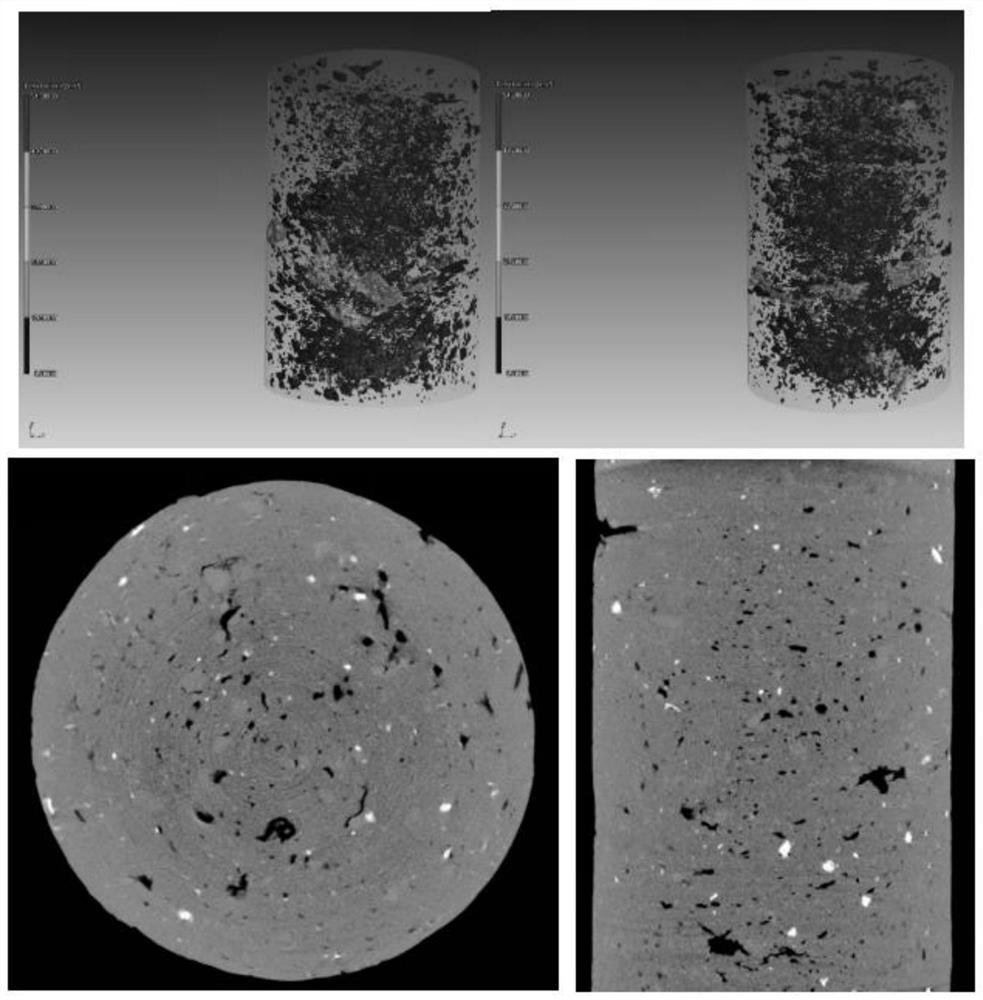

Image

Examples

Embodiment

[0037] The present invention provides an indoor sludge curing method based on a skeleton structure, comprising the following steps:

[0038] (1) Preparation of soil samples: weigh the silt samples, use natural drying or drying ovens below 45 ° C to air dry the silt soil samples, so that the moisture content is below 40%.

[0039] (2) Preparation of aggregates: the construction waste and cinder are mixed according to a certain proportion, graded crushing with intelligent screening machine, the first crushing to a particle size of less than 20mm, calcined in the muffle furnace, and then through the grading crusher, and the use of automatic screening system for intelligent screening and transmission, to obtain different particle size aggregates, and select aggregates with a particle size of 0.075-5mm.

[0040] Further, the cinder moisture content is not more than 2%.

[0041]Further, the mixing ratio of cinder to construction waste is 1:20.

[0042] Further, the calcination temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com