Novel drive-free LED filament lamp

An LED filament lamp without driver technology, which is applied in the direction of lighting and heating equipment, light sources, lighting devices, etc., can solve the problems that it is difficult to effectively realize the replacement of integrated driver modules, so as to save assembly process, reduce production cost and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

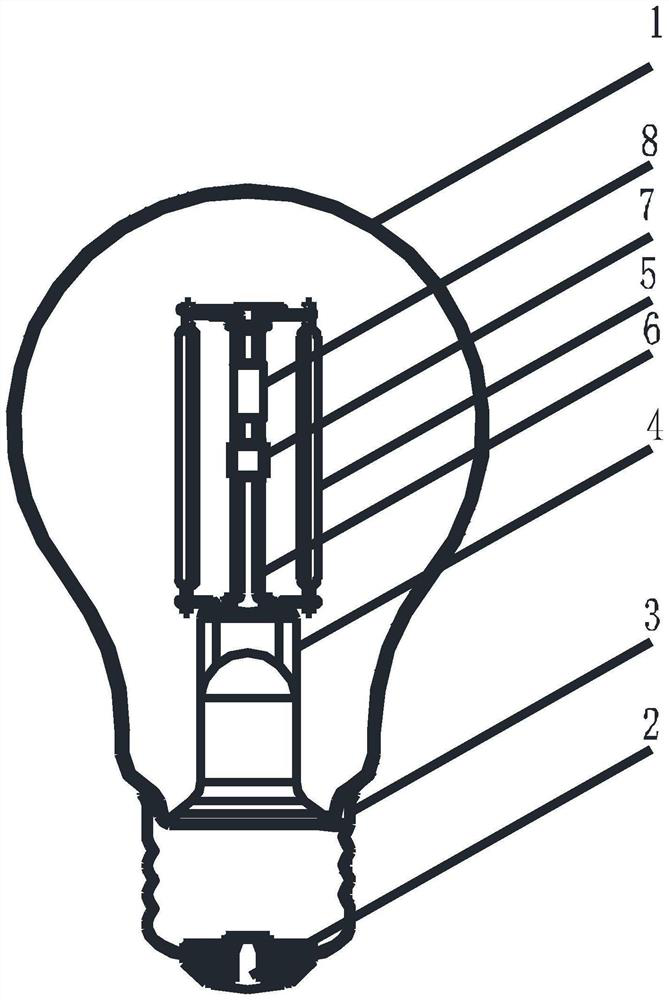

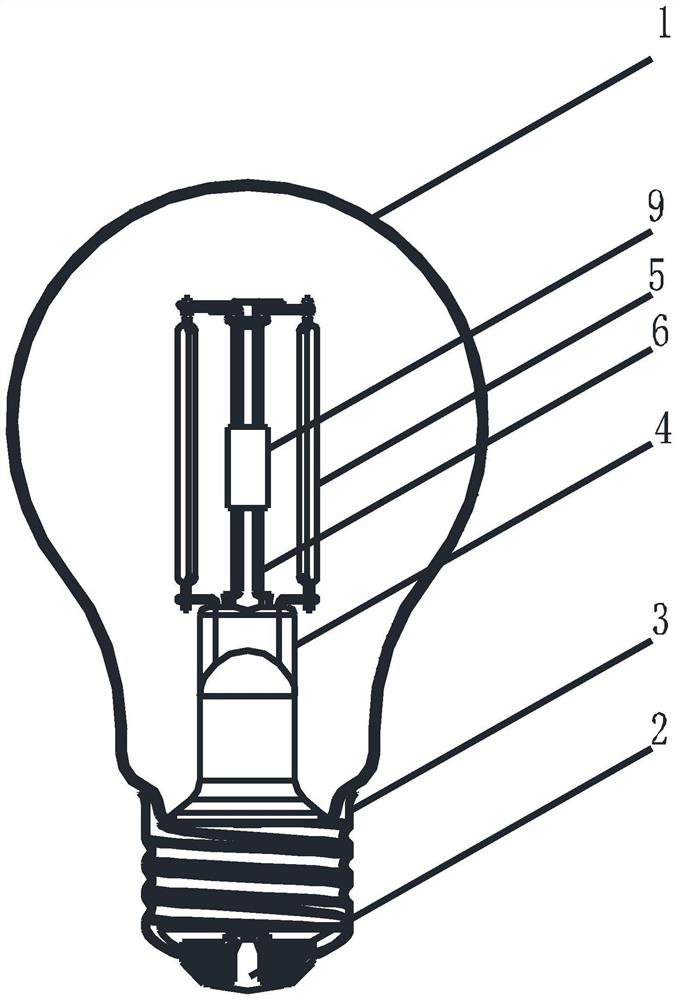

[0024] Example: A new type of driverless LED filament lamp of this example, such as figure 1 As shown, it includes a bulb 1 and a lamp cap connected to the bottom of the bulb 1, the bulb 1 is provided with a stem 4 connected to the lamp cap inside, the stem 4 is surrounded by a number of filaments 5, the stem 4 There is a current conversion device on it. The bottom of the lamp holder is the live wire terminal 2 of the lamp holder, the connection between the lamp holder and the bulb is the neutral wire terminal 3 of the lamp holder, the stem is used to set the circuit structure and filament, and the current conversion device is used to realize the conversion of alternating current to direct current and filter the current to prevent waves. Surge optimization.

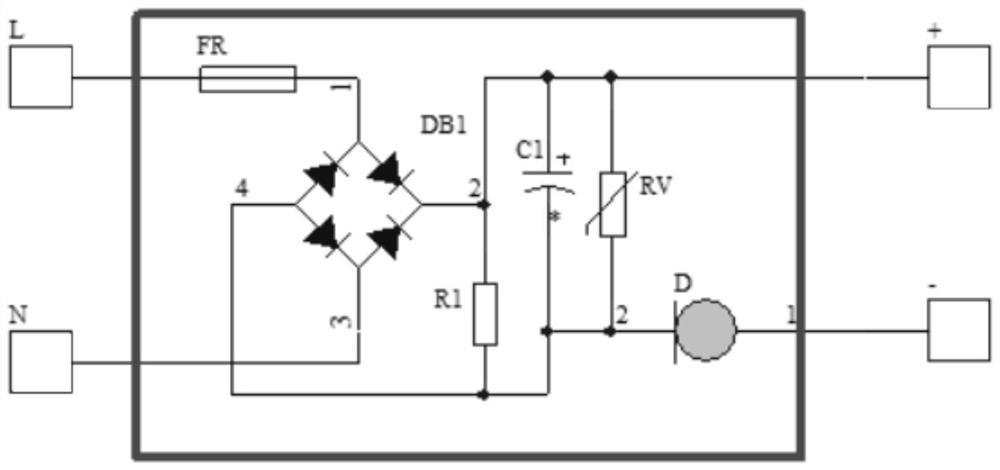

[0025] The current conversion device includes a sorting bridge stack DB17 and an electrolysis assembly 8 connected in sequence, the sorting bridge stack DB17 is connected to the AC input end, and the filtering electrolys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com