Electromagnetic directional valve control oil cleaning and detecting system and detecting method

An electromagnetic reversing valve and detection system technology, applied in mechanical valve testing, liquid/fluid solid measurement, heat measurement, etc., can solve problems such as the inability to guarantee the cleanliness of the oil, and the inability to monitor the specific parameters of the oil in real time, and achieve easy Operation and method are simple and effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

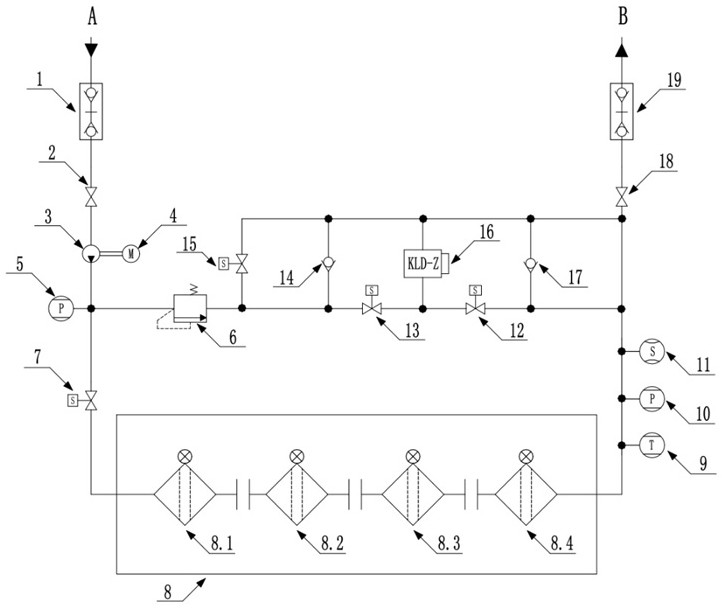

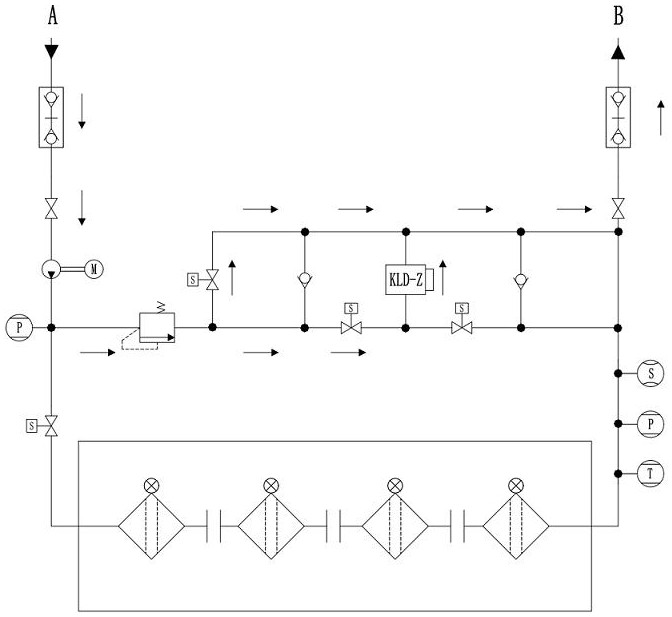

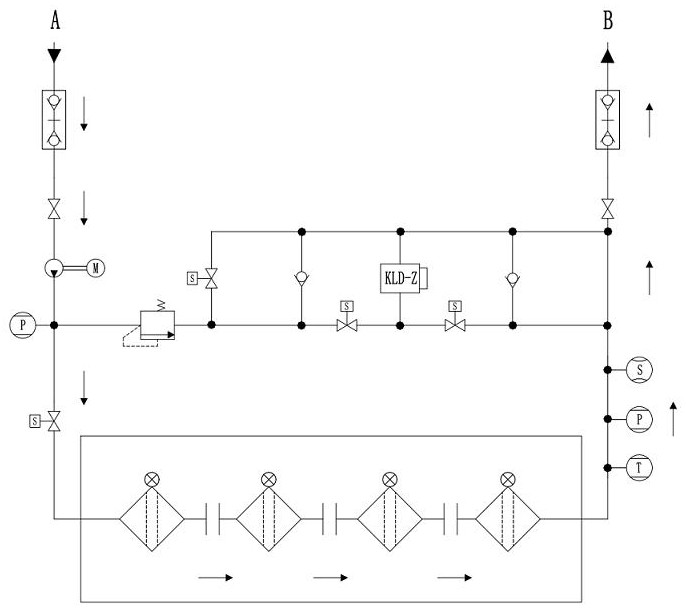

[0027] The present invention will be further described below through the accompanying drawings and embodiments. like Figures 1~7 As shown in the figure, an electromagnetic reversing valve controlled oil cleaning and detection system includes: an oil inlet quick-change joint 1 at the oil inlet A of the system, an oil inlet manual stop valve 2, a hydraulic pump 3, a frequency conversion motor 4, Oil inlet pressure transmitter 5, relief valve 6, first electromagnetic reversing valve 7, fine oil filter group 8, temperature sensor 9, oil outlet pressure transmitter 10, flow meter 11, second electromagnetic changer Directional valve 12, third electromagnetic reversing valve 13, first pressure resistance check valve 14, fourth electromagnetic reversing valve 15, oil particle size detector 16, second pressure resistance check valve 17, manual oil outlet Stop valve 18 , oil outlet quick-change joint 19 , control box 20 .

[0028] like Figures 1~7 As shown, the oil inlet quick-chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com