Model body and calibration method suitable for geometric correction of common track cone beam CT system

A technology of geometric correction and calibration method, which is applied in the directions of instruments, applications, and image enhancement for radiological diagnosis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The technical scheme of the present invention is described in detail below by the accompanying drawings, but the scope of protection of the present invention is not limited to the embodiments.

[0056] First, correct the preparation of mold bodies

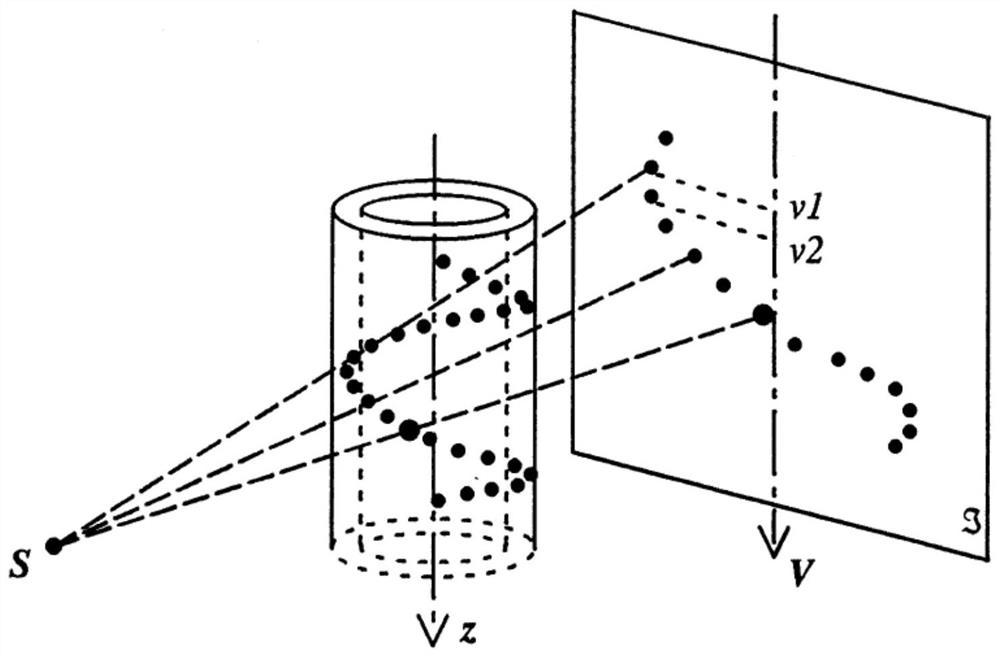

[0057] Figure 1It is a schematic diagram of the three-dimensional structure of the correction mold and the projection result. The correction mold takes the plexiglass cylinder as the main body, in which the spiral is inlaid with N metal balls, N≥5, the size of the pellets is inversely proportional to the resolution of the cone beam CT system, the system with high resolution selects smaller balls, the low resolution system selects larger balls, and the cone beam CT system equipped with a turntable with high circularity and high concentricity is used to scan the correction mold, and the projection data of the balls is obtained through the detector. There are two main reasons for the design of metal pellets as spiral distributions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com