Thickening or curing agent for oil

A technology of curing agent and oil agent, which is applied in the direction of food ingredients as curing agent, food ingredients as thickener, cosmetics, etc. It can solve the problem that the proportion of hydroxyl fatty acid is large, it cannot be thickened with cosmetic oil agent or curing agent, and it cannot reach Solve problems such as thickening of cosmetic oils, and achieve excellent effects of transparency and viscosity recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

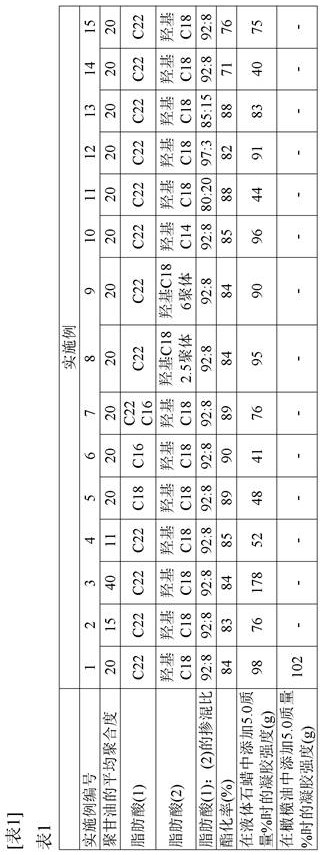

[0055] To the reaction flask was filled with 78.4g of polyglycerol with an average polymerization degree of 20 and 295.9g of behelpric acid (C22), 25.7g12-hydroxystearic acid (hydroxyC18), 0.8g of potassium hydroxide was added, and then the esterification reaction was carried out at 250 ° C, thereby obtaining a thickening or curing agent composed of polyglyceride fatty acid with a esterification rate of 84%. (In terms of constituent fatty acids, the doping ratio (mass ratio) of (1) is a straight-chain saturated fatty acid with a carbon atomic number of 16 to 24, and (2) is a hydroxy fatty acid and hydroxy fatty acid polypolymer, (1) :(2) is 92:8.) )

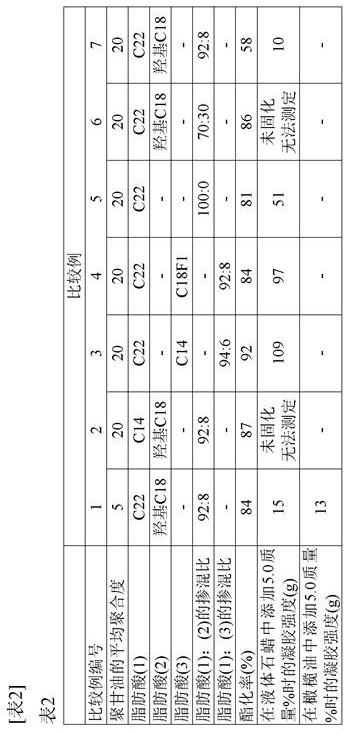

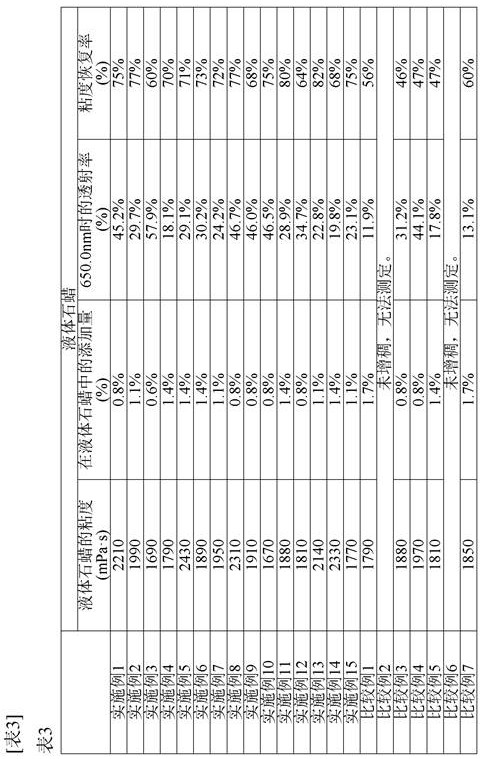

Embodiment 2~15、 comparative example 1~7

[0057]The same operation as Example 1, to the mixing ratio (mass ratio) described in Table 1, 2 to the reaction flask into the reaction flask of the average polymerization of polyglycerol and fatty acids (1) ~ (3) recorded in Table 1, 2, adding 0.8g potassium hydroxide, and then esterification reaction at 250 ° C, thereby obtaining a thickening or curing agent composed of polyglycerol fatty acid esters. The esterification rate is shown in Tables 1 and 2. It should be noted that the "hydroxyL C18 2.5 polymer" used in Example 8 is modulated by loading 300.0g 12-hydroxystearic acid into a reaction flask, adding 0.8g of potassium hydroxide, and then dehydration condensation reaction at 250 ° C until the acid value is 77.6. Further, the "hydroxyL C186 polymer" used in Example 9 is modulated by filling the reaction flask with 300.0g 12-hydroxystearic acid, adding 0.8g of potassium hydroxide, and then dehydration condensation reaction at 250 ° C until the acid value is 32.8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com