Operating system of picking end effector of fruit bunch picking robot

A technology for picking robots and end effectors, applied in picking machines, closed-circuit television systems, instruments, etc., can solve the problems of not being easy to obtain, high labor costs, and lack of recognition ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described below with specific examples, but not intended to limit the present invention.

[0017] my country's agricultural mechanization is more concentrated in the field, and large-scale machinery such as tractors and harvesters are becoming more and more popular, and field planting has gradually become digital and unmanned. For the current fruit production, the production of large-scale orchards consumes a lot of human resources, and the economic cost of the picking process is very high. Especially for fruit picking, it is time-consuming and laborious, and a lot of water is obviously seasonal. , fast picking has also become the basis for ensuring its high-quality sales.

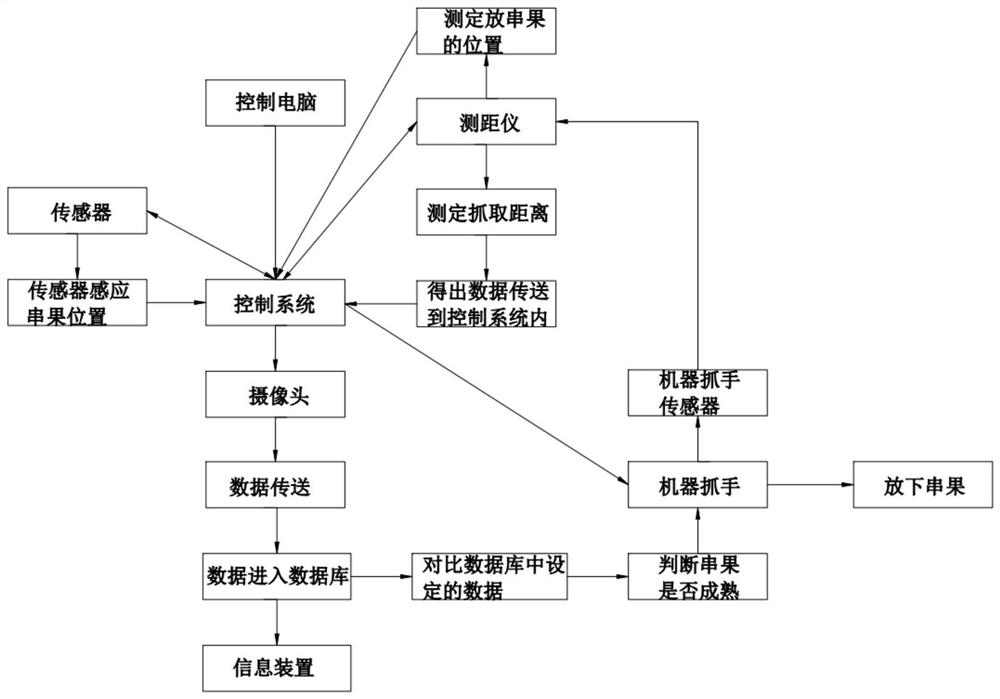

[0018] The fruit bunching robot picking end effector operation system. The picking system includes a control computer, a control system and a machine gripper. To work, the picking robot controls the sensor installed on the robot to sense the position of the fruit bunch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com