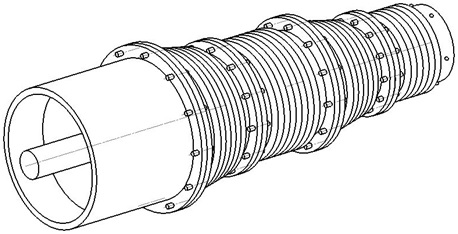

Isothermal extrusion die and extrusion method thereof

A technology of isothermal extrusion and die, applied in the field of alloy processing, can solve the problems of long heating time and low efficiency, and achieve the effect of increasing the output rate, increasing the preheating temperature and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

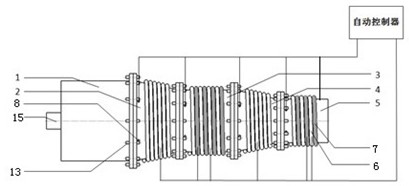

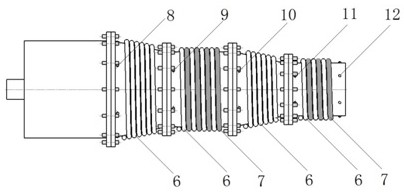

[0044] Rapid extrusion process: use the gradient temperature form of heating 100℃ / 1 hour, heat the extrusion cylinder 1 to 450℃~480℃, heat the mold to 460℃~500℃, and keep the temperature for 2-4 hours; A proper amount of aluminum rods are heated to 460℃~500℃ in a resistance furnace, and kept for 30 minutes; after the mold is assembled, the mold is locked in the extrusion position, and the heated aluminum rods are raised to the alignment position of the material tank by the feeding frame; Open the five sets of temperature sensor controllers, cooling pipes 6 and compensation pipes 7; the main cylinder is extruded forward, and the heat loss of each section in the rapid extrusion process is less than the temperature increase caused by extrusion. Both the environmental and practical correction results work, and the compensation pipe 7 does not work; the primary deformation cylinder 2 cooling pipe 6 is cooled according to the theoretical calculation and practical correction results t...

Embodiment 2

[0046] Rapid extrusion process: use the gradient temperature form of heating 100 ° C / 1 hour, heat the extrusion cylinder 1 to 450 ° C, heat the mold to 480 ° C, and keep it for 2-4 hours; take an appropriate amount of aluminum rod into the resistance The furnace is heated to 480°C and kept for 30 minutes; after assembling the mold, lock the mold in the extrusion position, and use the feeding rack to raise the heated aluminum rod to the alignment position of the material tank; open the five sets of temperature sensors, cool down Pipe 6 and compensation pipe 7; the main cylinder is extruded forward, the heat loss of each section in the rapid extrusion process is less than the temperature increase caused by extrusion, and each cooling pipe 6 works according to theoretical calculation, heat dissipation environment and practical correction results, The compensation tube 7 does not work; the cooling tube 6 of the primary deformation cylinder 2 is cooled according to the theoretical c...

Embodiment 3

[0049] Medium-speed extrusion process: adopt the form of heating 100℃ / 1 hour gradient, heat the extrusion cylinder 1 to 300℃, heat the die to 320℃, and keep the temperature for 2-4 hours; The resistance furnace was heated to 350°C, and kept for 30 minutes; further, after the mold was assembled, the mold was locked in the extrusion position, and further, the heated magnesium rod was raised to the alignment position of the material gallbladder using the feeding rack; open Temperature sensor controller, compensation pipe 7 and cooling pipe 6, the main cylinder is extruded forward; in the medium-speed extrusion process, the heat loss in the transition zone and the forming zone is greater than the temperature increase caused by the extrusion friction, the compensation pipe 7 works, and the extrusion The heat loss in the area is less than the temperature increase caused by the extrusion, and the cooling pipe 6 works; the cooling pipe 6 of the primary deformation cylinder 2 is cooled ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com