Method for manufacturing strip for bearing

A strip and bearing technology, which is used in the manufacture of bearing strips, the manufacture of bimetal strips containing Wuxi aluminum alloy, and can solve the problem that aluminum alloy bearings cannot be used.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

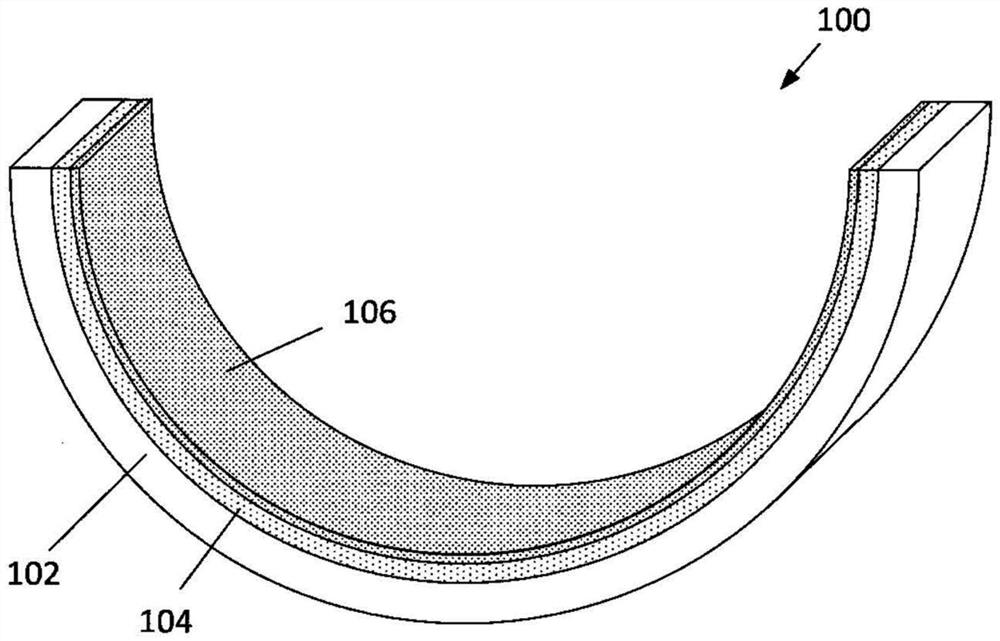

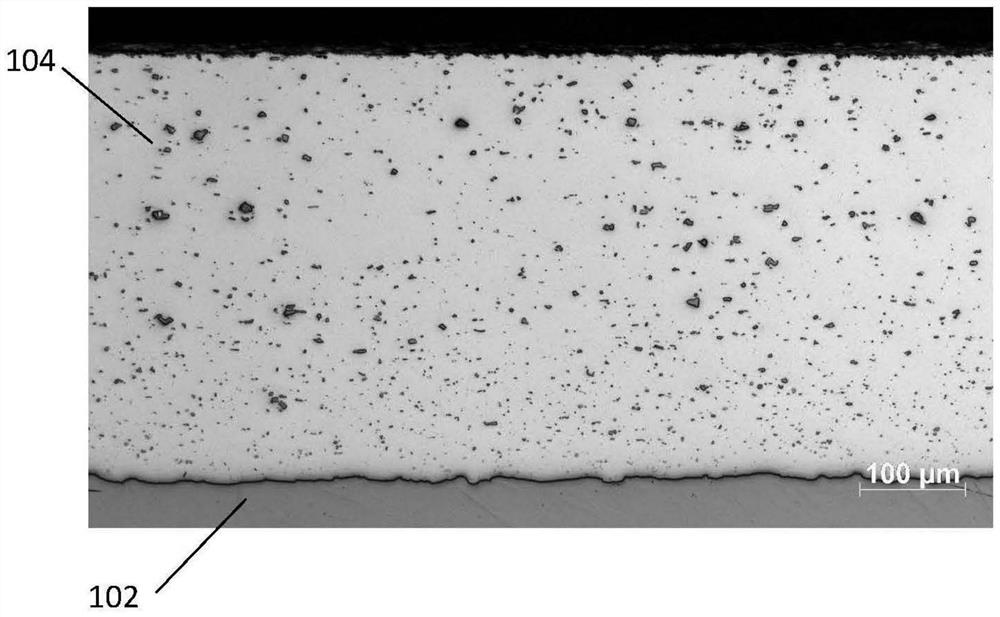

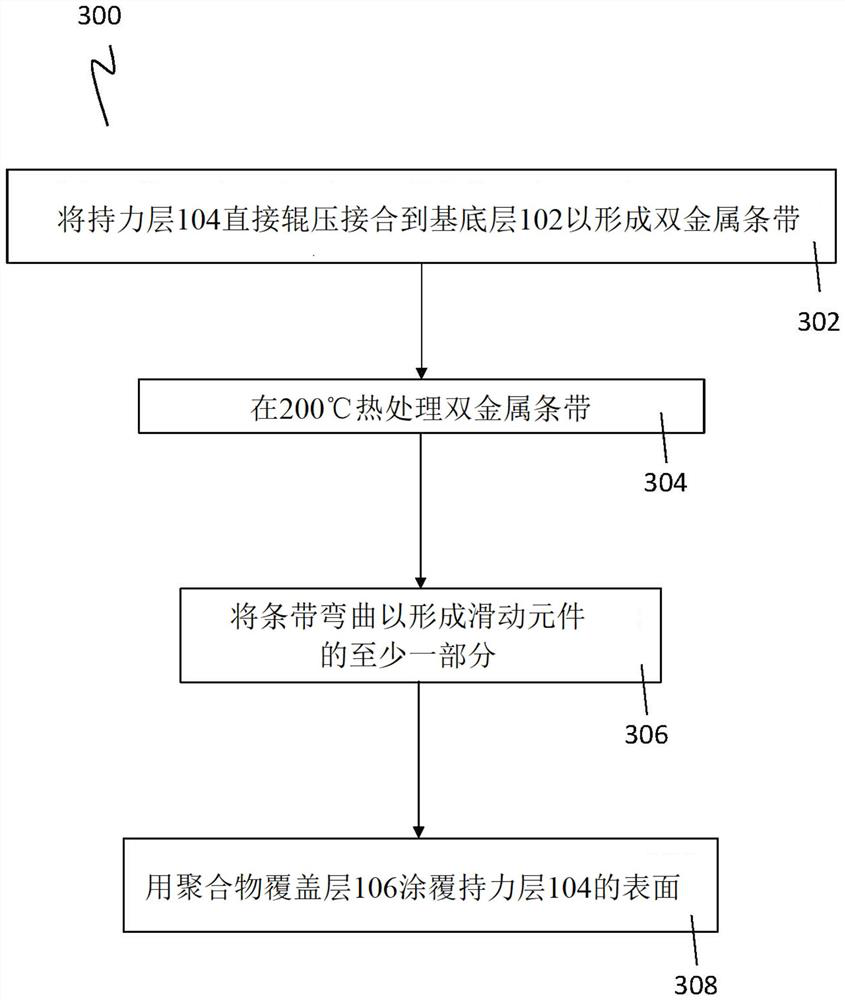

[0085] figure 1 A portion of a bimetallic bearing 100 is shown, including: a backing or base layer 102, a holding layer 104 of a soft phase-free aluminum alloy, and a polymer cover or running layer 106.

[0086] The base layer 102 is made of steel and may optionally contain up to about 1 wt % copper. Bearing 100 does not include an intermediate layer because the aluminum alloy of holding layer 104 is roll bonded directly to the steel of base layer 102 .

[0087] The surface of the support layer 104 of the tape may be coated 308 with a polymer cover layer 106 . The strip can be bent to form at least part of the bearing, for example as figure 1 Half bearing pads of bimetal bearing 100 shown.

[0088] A suitable polymeric cover layer 106 may be as described in GB0822346A. The polymer cover layer 106 may comprise polyimide / amide plastic and / or fluoropolymer.

[0089] The aluminum alloy is a standard commercially available aluminum alloy of the wrought aluminum-manganese serie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com