Manufacturing method of outer-layer thin circuit of flexible circuit board

A technology for flexible circuit boards and manufacturing methods, which is applied in the fields of printed circuit manufacturing, removal of conductive materials by chemical/electrolytic methods, printed circuits, etc., which can solve the problems that dry films cannot meet the requirements of flexible circuit board manufacturing processes, etc., and achieve increased filling and the ability to cover holes and the effect of thickening the thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

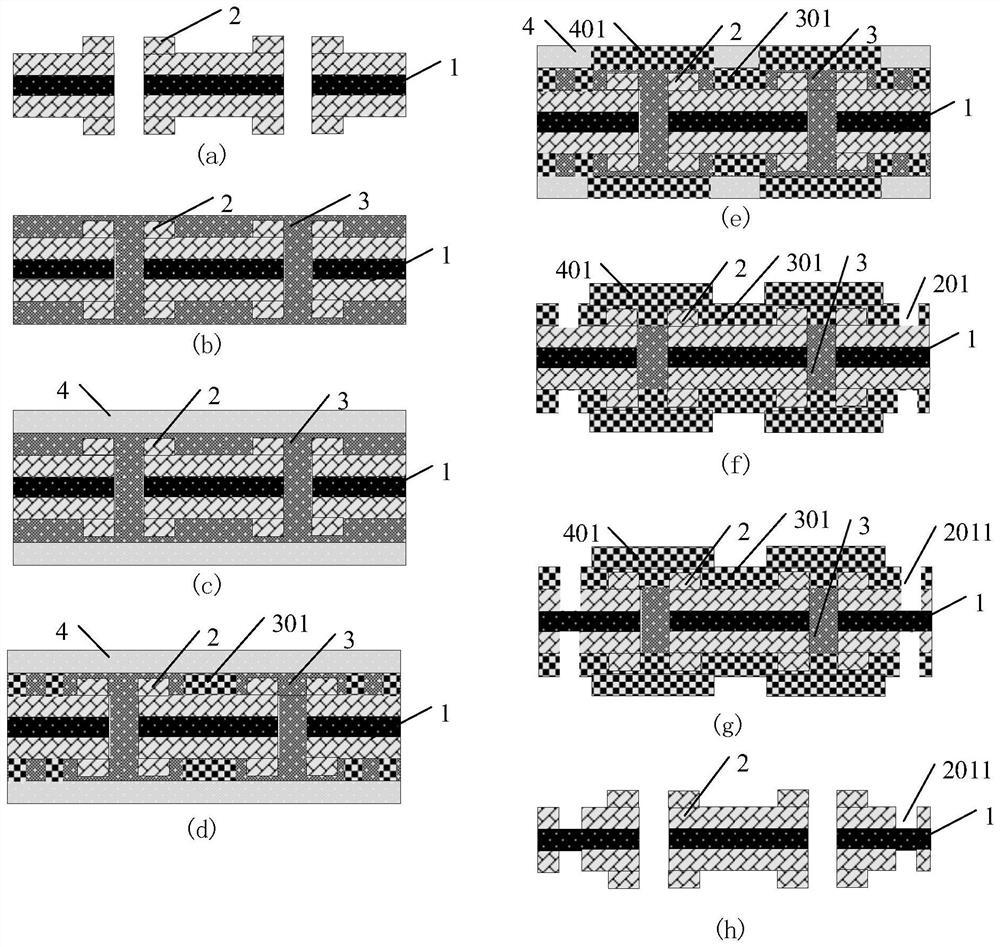

[0045] like figure 1 As shown, two types of dry films with different photosensitive wavelengths were selected to achieve differential curing. The first layer is a high-sensitivity LDI high-resolution, high-adhesion dry film with a 405nm light source. Then choose ordinary UV dry film (non-LDI dry film) with weak or no absorption at 405nm light source. The first step is to use a 405nm light source to perform pattern exposure except for the through-hole area. Because the upper layer of dry film has almost no absorption of 405nm light waves, the light waves reach the lower layer of dry film, that is, the curing of the bottom layer of dry film is completed, and the difference between the two layers of dry film is realized. cured. The second step uses a 355nm (or 375nm) light source to implement only the through-hole area curing, while controlling the degree of reaction of the deep dry film in the hole.

[0046] like figure 1 As shown in (a), a double-sided board is drilled, the...

example 2

[0056] 1. The first layer is a dry film of LDI with high resolution, high adhesion, and not limited to laser light sources. First, use a 355nm (or 375nm) or 405nm or mixed wavelength laser light source for exposure outside the through-hole area, tear off the surface PET, and then paste a second layer of dry film. In order to improve the exposure efficiency, ordinary dry film UV dry film or LDI dry film can be used for the second layer of dry film. In order to improve the efficiency, LDI dry film is preferred, and a dry film with strong absorption of 355nm or 375nm wavelength laser is selected for through-hole area exposure. Realize the curing of the through-hole area, enhance the porosity, and at the same time control the reaction degree of the deep dry film in the hole, and it is easy to complete the film removal.

[0057] 2. Since the second exposure is only for the through hole area, during development, the dry film outside the upper through hole area will be revealed by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com