Piston pin hole lining structure

A technology of piston pin hole and piston pin, applied in the direction of piston, engine lubrication, machine/engine, etc., can solve the problems of increasing the surface temperature and specific pressure of the piston pin hole, destroying the lubricating oil film, breaking, etc., to improve reliability and reliability. Service life, reduced risk of cracking, increased contact area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to better illustrate the purpose and advantages of the present invention, the content of the invention will be further described below with reference to the accompanying drawings and examples.

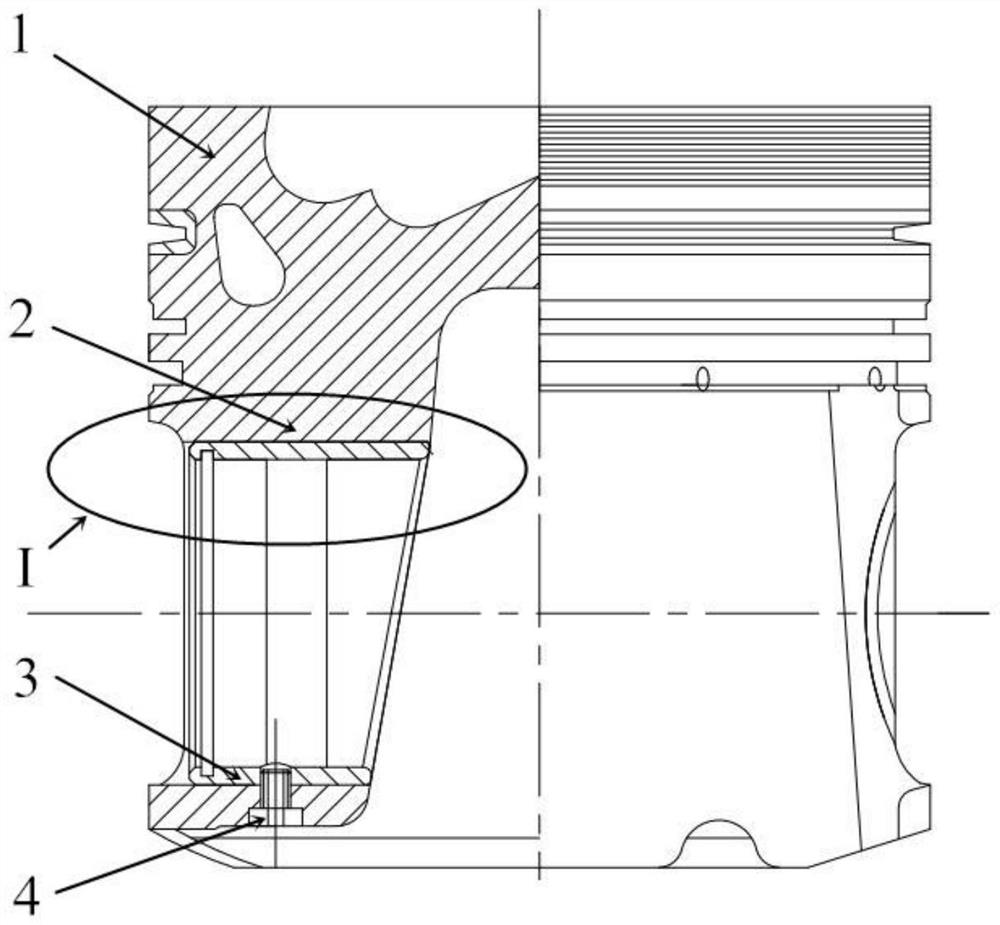

[0023] like figure 1 As shown, a piston pin hole bushing structure disclosed in this embodiment is provided on the piston 1 with a piston pin hole 2 for carrying the piston pin. A piston pin hole bushing 3 is installed in the piston pin hole 2 , and the piston pin hole bushing 3 is installed into the piston pin hole 2 through an interference fit. A countersunk head threaded through hole is opened on the back side of the lowest point of the piston pin hole 2, and a hollow fixing bolt 4 is installed through the countersunk head threaded through hole. between the inner surfaces to ensure that the normal operation of the piston pin is not affected. The piston 1 and the piston pin hole bushing 3 are fixed together by the thread on the hollow fixing bolt 4 . The hollow str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com