Treatment gas suction structure and exhaust gas treatment device

An exhaust gas treatment device and gas treatment technology, which is applied in the direction of separation device, gas treatment, liquid variable capacity machinery, etc., can solve the problems of exhaust gas treatment device failure, low processing efficiency of gas treatment, etc., and achieve the effect of preventing products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

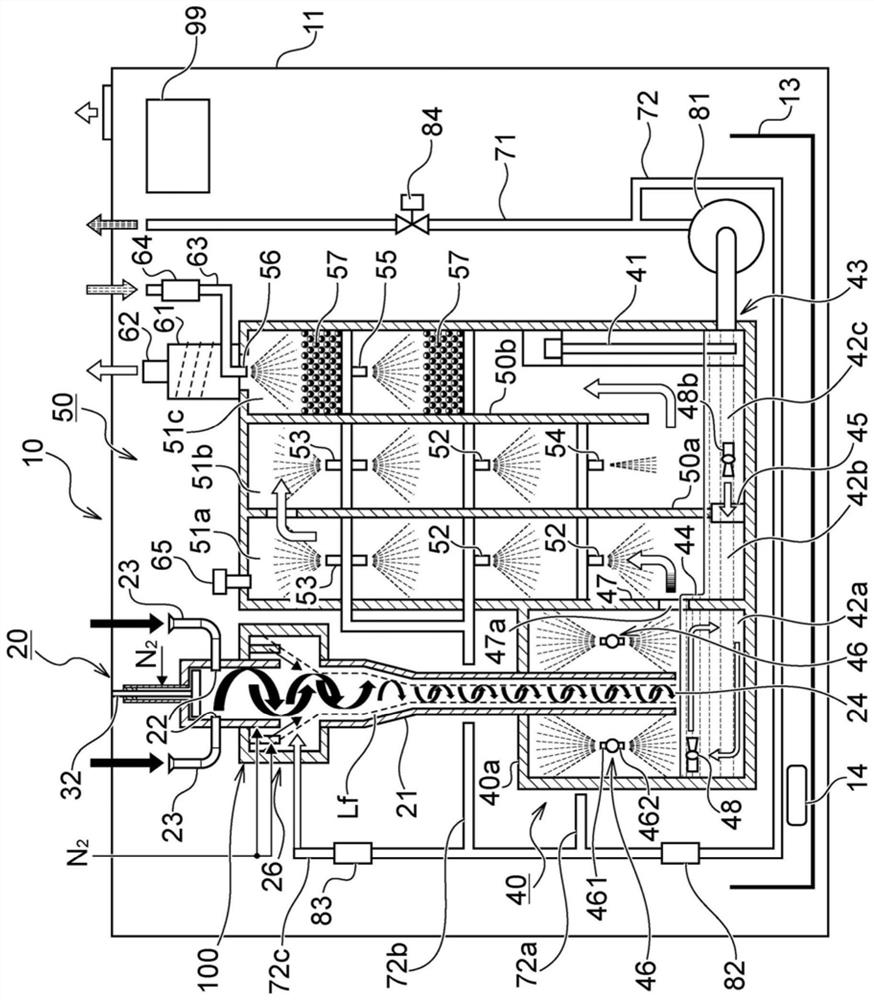

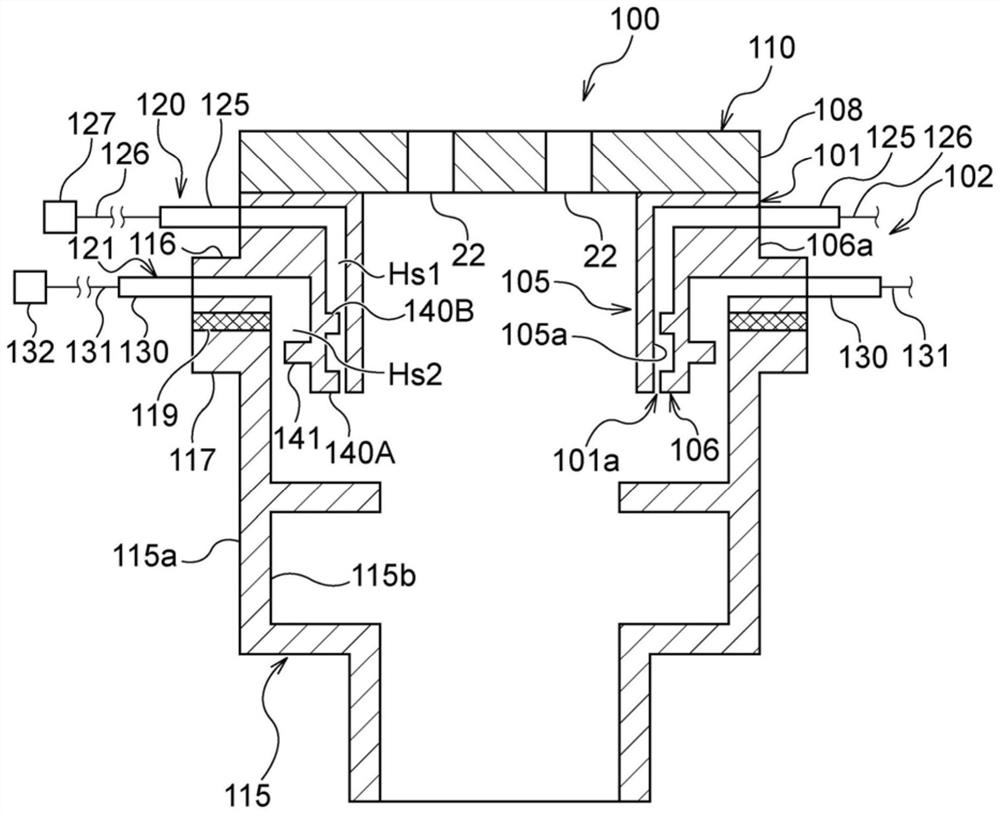

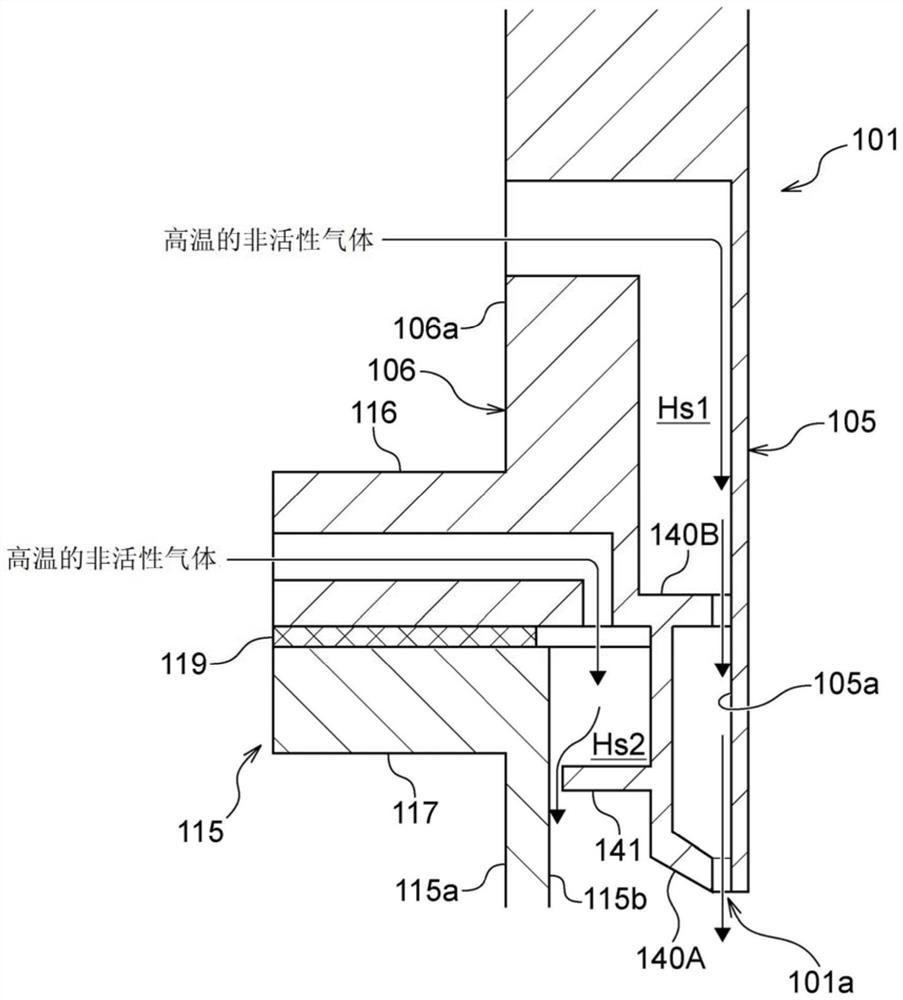

[0120] Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings. In the drawings described below, the same or equivalent structural elements are denoted by the same reference numerals, and overlapping descriptions are omitted. The exhaust gas treatment apparatus of the present embodiment is a wet exhaust gas treatment apparatus that detoxifies the treatment gas by contacting the treatment gas with a liquid, and can be used as one of manufacturing facilities for semiconductors, liquid crystals, solar panels, and LEDs, for example.

[0121] figure 1 It is a figure which shows one Embodiment of an exhaust gas processing apparatus. The exhaust gas treatment device 10 is installed to detoxify the gas (processing gas) from the vacuum pump. The primary side (upstream side) of the exhaust gas treatment device 10 is connected to a vacuum pump not shown. In addition, the exhaust gas treatment device of the present embodiment may ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com