A kind of preparation method of copper-plated foam carbon

A carbon foam and copper plating technology, applied in liquid chemical plating, metal material coating process, coating, etc., can solve the problems of poor mechanical properties and thermal conductivity, and achieve the goal of lowering temperature, reducing cost, and increasing resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

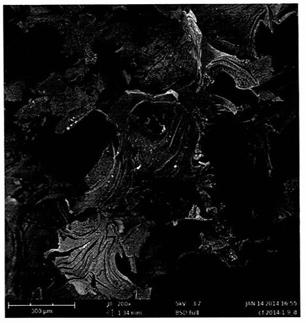

Image

Examples

Embodiment 1

[0031] (1) Place a carbon foam matrix of 25.00mm×25.00mm×50.00mm in size by 60g / LNaOH, 20g / LNa 2 CO 3 , 20g / LNa 3 PO 4 In the degreasing liquid composed, the water bath was heated to 55°C, ultrasonically treated for 20min, and washed with water until neutral.

[0032] (2) Oxidize the surface of the foamed carbon, put the foamed carbon after degreasing into nitric acid with a mass fraction of 60%, ultrasonically treat it at room temperature for 10 minutes, wash it with water until neutral; take out the foamed carbon and place it in an oven at 100°C Dry to constant weight and weigh.

[0033] (3) Carry out sensitization treatment to foam carbon, place the foam carbon after nitric acid oxidation by 5%HCl, 20g / LSnCl 2 and a small amount of tin particles, sensitized at room temperature in a vacuum chamber with a vacuum pressure of 0.01-0.1MPa for 20 minutes, then soaked in deionized water for 10 minutes, and washed until neutral.

[0034] (4) Carry out activation treatment to f...

Embodiment 2

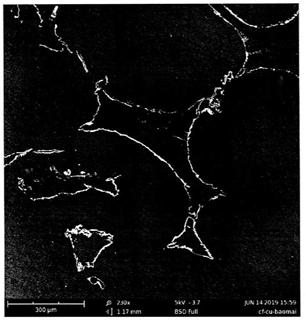

[0037] The difference between this implementation case and Case 1 is that after the plating solution has gone through 3 cycles in step (5), the foamed carbon substrate is taken out from the plating solution, washed with water to neutrality, and benzotriazepine with a mass fraction of 0.08 to 0.8% The azole alcohol solution was vacuum passivated for 10 minutes, put it in a vacuum oven at a temperature of 90°C, dried for 4 hours, took it out and weighed it, and carried out appearance, thickness and performance tests. Other steps and parameters were the same as those in Example 1, as shown in Figure 2 .

Embodiment 3

[0039] This implementation case is different from case one in that step (5) puts activated foam carbon into 200mL by 20g / L copper sulfate, 25mL / L formaldehyde, 25g / L sodium edetate, 14g / L sodium tartrate, In the plating solution composed of 20mL / L stabilizer, adjust the pH of the plating solution to 12.5 with sodium hydroxide solution, place the plating solution in a vacuum chamber, the pressure in the vacuum chamber is 0.06MPa, and carry out vacuum reaction at room temperature for 10min. 400~800 / min magnetic stirring, stirring for 10min, then add vacuum and mechanical stirring to the electroless copper plating process. The alcohol solution of benzotriazole with a mass fraction of 0.08-0.8% is vacuum passivated for 10 minutes, placed in a vacuum oven at a temperature of 90°C, dried for 4 hours, taken out and weighed for appearance and performance tests. Other steps are the same as The parameters are the same as the implementation case 1, as attached image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com