Large low-temperature storage tank inspection and maintenance method

A low-temperature storage tank, large-scale technology, applied in container filling method, container discharge method, fixed-capacity gas storage tank, etc., can solve the problems of high maintenance cost and long maintenance period, and achieve low maintenance cost, short maintenance period, Ensure the effectiveness of the inspection and maintenance construction cycle

Pending Publication Date: 2022-06-21

CHINA NAT AIR SEPARATION ENG CO LTD

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The design life of the storage tank is generally 20 years. When the storage tank reaches the design life or when the owner thinks it is necessary to overhaul the storage tank during operation, it is necessary to open the tank for inspection of the low-temperature storage tank. However, the inspection period of the tank opening inspection is long and the maintenance cost is high. question

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

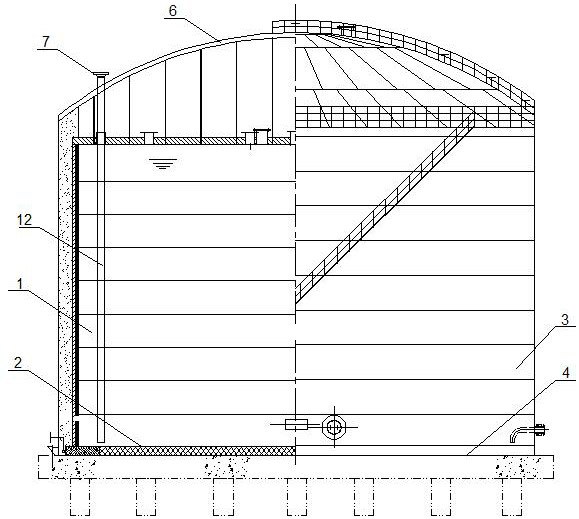

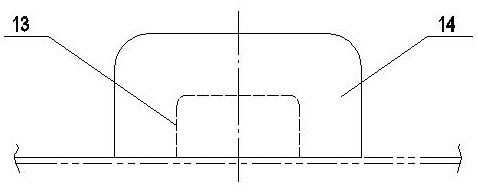

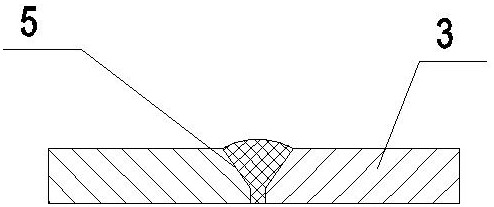

The invention provides a large low-temperature storage tank maintenance method which is reasonable in design, short in maintenance period and low in maintenance cost. The method comprises the following steps: (1) detecting a bottom plate of an inner tank; (2) detecting an inner tank wall plate; (3) detecting an outer tank bottom ring plate; (4) detecting the wall plate of the outer tank; (5) transforming a drain hole; (6) interlayer pearlife is removed; (7) tank wall elastic felt replacement; (8) ceiling glass wool replacement; (9) replacing a multi-point thermal resistor; (10) a servo liquid level meter is additionally arranged and used for measuring the liquid level of liquid; and (11) adding an average thermometer for measuring the temperature of the liquid.

Description

technical field [0001] The invention relates to a large-scale low-temperature storage tank inspection and maintenance method, in particular to the inspection and maintenance of large-scale atmospheric-pressure low-temperature storage tanks storing low-temperature media, such as LNG, liquid ethylene, liquid propylene, liquid ammonia and other low-temperature storage tanks. Background technique [0002] More and more low-temperature storage tanks are used in the energy and petrochemical industries. These low-temperature storage tanks mostly adopt a double-layer structure, and glass bricks, expanded perlite and glass wool are used as thermal insulation materials between the inner tank and the outer tank. The design life of the storage tank is generally 20 years. When the storage tank reaches the design life or when the owner thinks it is necessary to overhaul the storage tank during operation, it is necessary to open the tank for inspection of the low-temperature storage tank. H...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F17C3/04F17C13/00F17C13/02G01N27/83G01N27/84G01N29/04

CPCF17C3/04F17C13/00F17C13/02F17C13/021G01N27/83G01N27/84G01N29/04F17C2201/0109F17C2203/0337F17C2203/0304F17C2203/0629F17C2205/0126F17C2209/227F17C2209/228F17C2209/238F17C2209/23F17C2260/015F17C2260/048

Inventor 魏强张晓东李积杰张春方赵方华方其周思雯张丹胡水云江炜梁振江

Owner CHINA NAT AIR SEPARATION ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com