Automatic cutting data recorder

A recorder and automatic technology, applied in the direction of instruments, scientific instruments, comprehensive factory control, etc., can solve problems such as internal friction angle and cohesion distortion, influence on shear data, slow acquisition speed, etc., to achieve enhanced anti-interference ability, Cutting data is accurate and the effect of saving communication time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

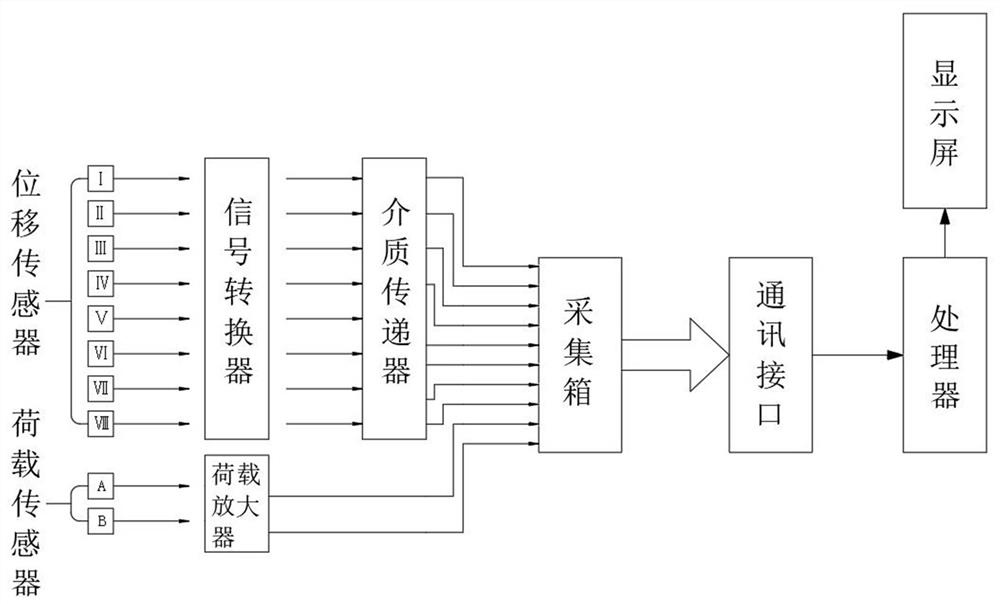

[0024] It should be noted that due to the frequent startup of high-power equipment at the test site, and the wireless communication equipment used for real-time communication will generate electromagnetic interference, which will lead to distortion of the detection data collected in the shear data recorder, and the shear resistance of the rock cannot be accurately obtained. cutting strength. At this point, the anti-jamming methods used in the prior art generally include inserting data filtering subroutines into the program to improve the anti-jamming capability, or selecting low-frequency components to reduce distortion in signal transmission and reduce signal interference. Based on the above problems, the applicant uses the signal processing module to analyze, compare and gain the cut data signal. The gain process is specifically: the signal processing module decomposes the data signal into variables, and the I / The Q signal is processed to obtain the baseband signal of the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com