Micro LED display device and preparation method thereof

A technology for display devices and passivation layers, which is applied in the manufacturing of semiconductor/solid-state devices, semiconductor devices, electric solid-state devices, etc., can solve the problems of color purity decline, small pixel pitch, crosstalk, etc., and achieve the effect of shortening preparation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

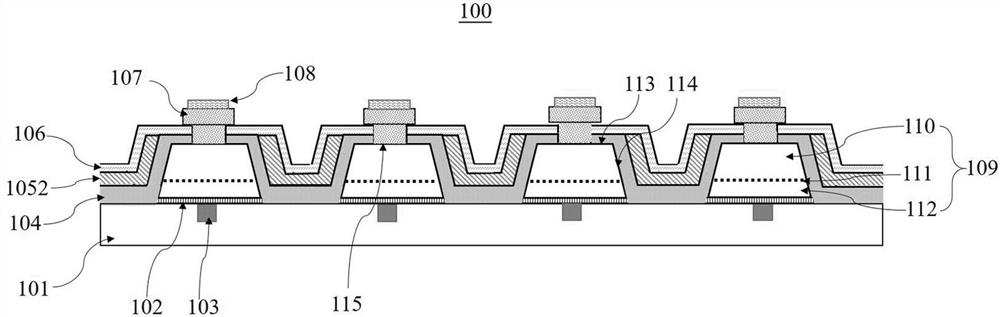

[0082] In some embodiments, the electrode layer 107 is made of a transparent material, such as a transparent conductive film, as the ohmic contact layer and the light outlet of the LED unit 109 .

[0083] In some embodiments, in order to improve the collimation of the light output, a Bragg reflector 108 can also be deposited at the light output port, see Figure 19 , the Bragg reflector 108 is located on the electrode layer 107, and the reflectivity of the Bragg reflector 108 is between 50%-70%; The reflectivity of the mirror 108 is smaller than that of the reflective metal at the bottom of the LED unit 109 .

[0084] In some embodiments, the entire surface of the Bragg mirror 108 is coated on the electrode layer 107 .

[0085] In some embodiments, when the electrode layer 107 is coated on the entire surface of the LED unit 109, and the Bragg reflector 108 is coated on the entire surface of the electrode layer 107, the electrode layer 107 and the Bragg reflector 108 are made ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com