Large-breadth laser cutting machine convenient for sucking and removing machining chips

一种激光切割机、大幅面的技术,应用在金属加工设备、激光焊接设备、制造工具等方向,能够解决费时费力、激光切割设备无法一次性完成切割、难以保证多组激光切割设备对接精度等问题,达到保证水平精度、便于安装拆卸和更换的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

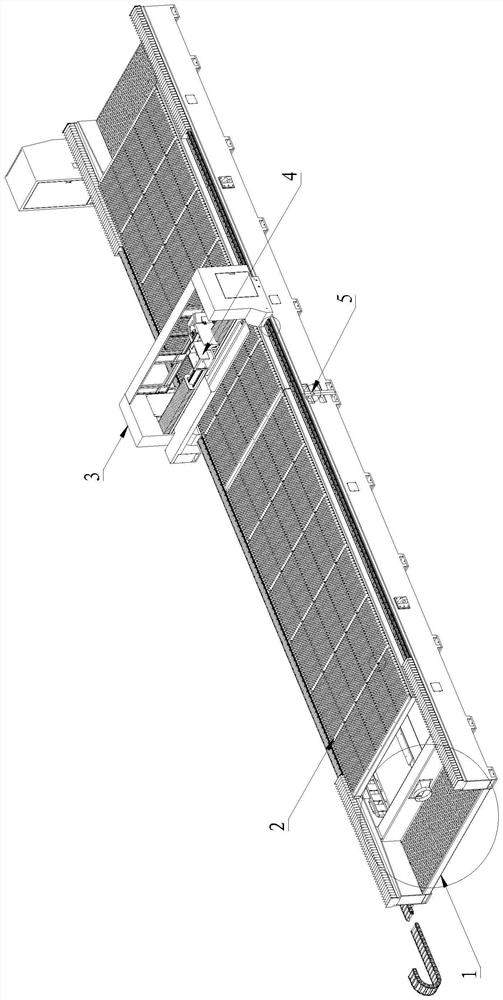

[0072] Please refer to Figure 1 to Figure 13 As shown, the first embodiment of the present invention is: a large-format laser cutting machine, comprising a machine tool 1 and a material racking mechanism 2, a gantry mechanism 3, a cutting mechanism 4, a positioning mechanism, a spacer Heat mechanism 6 and dust removal mechanism 7;

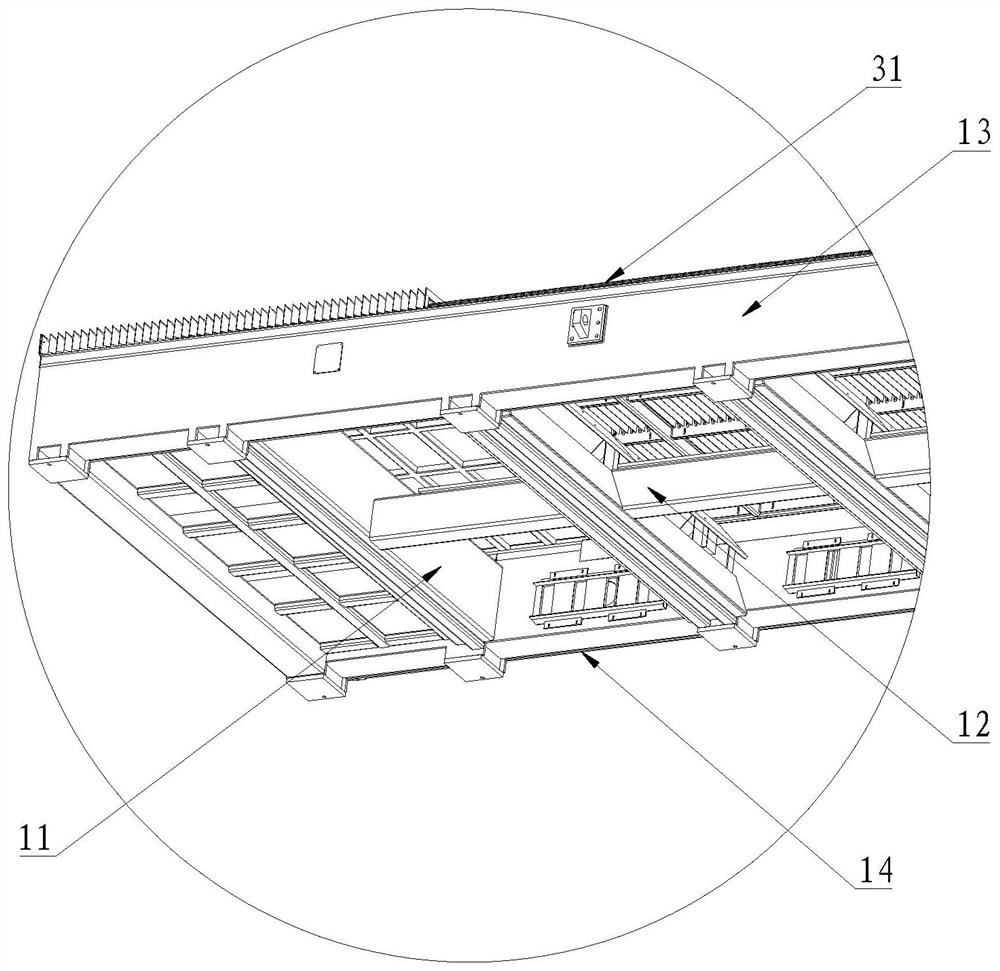

[0073] The machine tool includes a main beam 11, a main longitudinal beam 12, a first side beam 13 and a second side beam 14. Two or more of the main beams 11 are arranged at intervals along the first horizontal direction. Both the side beam 13 and the second side beam 14 are arranged along the second horizontal direction perpendicular to the first horizontal direction, the main longitudinal beam 12 is erected on the main cross beam 11, and the two ends of the main cross beam 11 are respectively connected to the second horizontal direction. The side beams 13 and the second side beams 14 are connected, the two first side beams 13 are butted along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com