PET (polyethylene terephthalate) mildew-proof material as well as preparation method and application thereof

A technology of anti-mold and anti-mold agent, applied in the preparation of multi-layer anti-mold structure, PET anti-mold material and its preparation, field of anti-mold material, can solve the problems of long crystallization cycle and difficulty in taking advantage of advantages, and achieve construction Simple, excellent anti-mold performance, and the effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] In some embodiments, the preparation method specifically includes:

[0037] Mix PET matrix resin, antifungal agent, antioxidant and other additives evenly to form a mixture;

[0038] The mixture is heated to a selected temperature for melt extrusion, and after being extruded and pelletized by a screw, the obtained mold-resistant PET masterbatch is injected or blow-molded to obtain the PET mold-resistant material. Wherein, the selected temperature is 260-290°C, preferably 270-280°C.

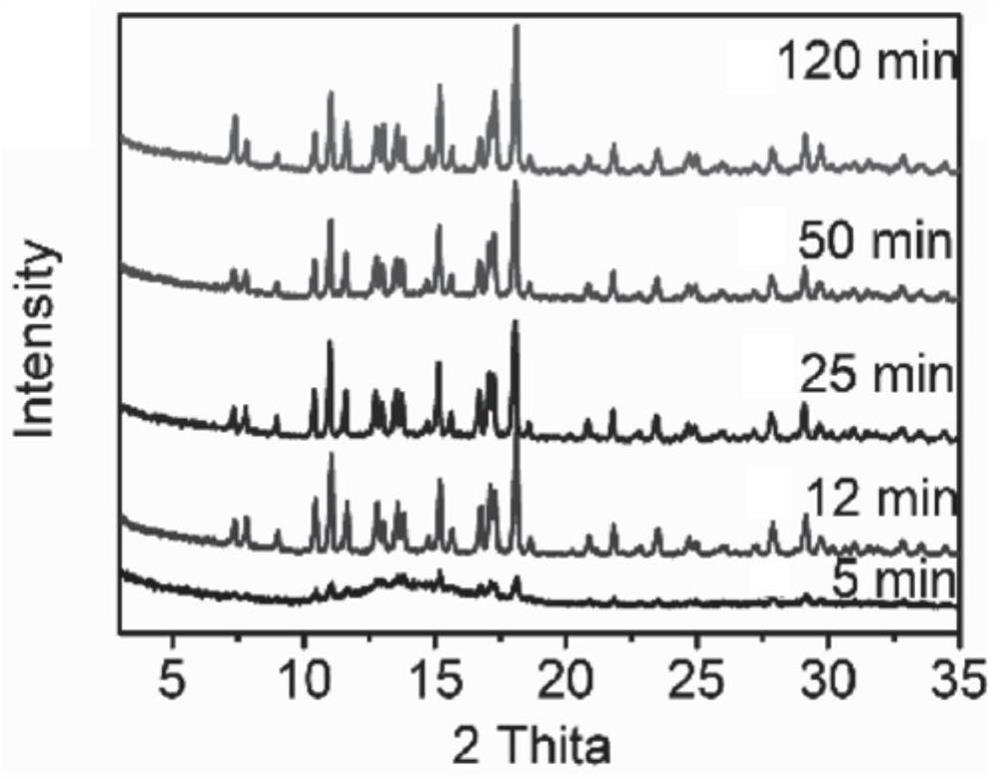

[0039]The applicant unexpectedly found that when ZIF-8 is compounded with PET matrix resin and additives at an addition amount of 3wt% or less, especially 5wt‰~1wt%, not only can the formed PET anti-mold material have excellent anti-mold properties For example, the anti-mildew grade of Aspergillus niger (A. niger), Penicillium funiculosum (P. funiculosum), etc. is not lower than grade 1, and it also shows good nucleation effect, which can effectively shorten the nucleation cycle of PET, T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com