Preparation process of durable automobile paint

A preparation process and technology for automotive paint, which can be applied to coatings, fire-resistant coatings, etc., and can solve problems such as bubbles in automotive paint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

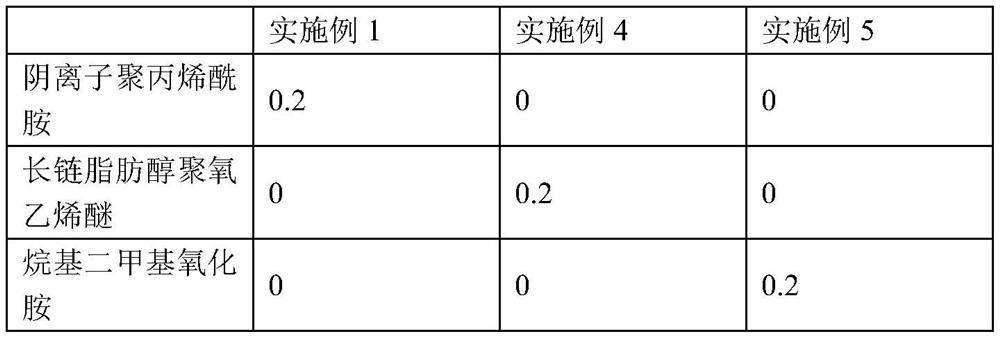

Examples

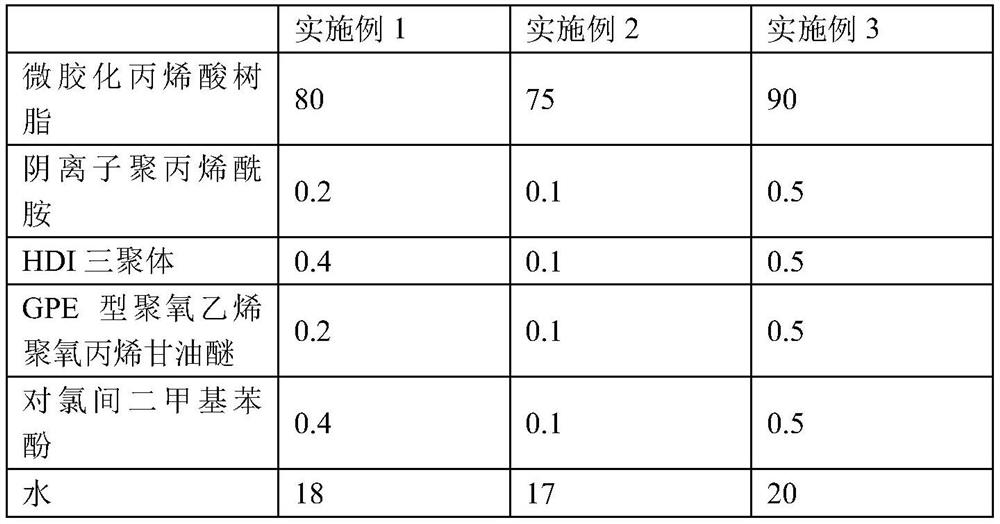

Embodiment 1

[0033] The preparation process method of a kind of durable car paint provided by embodiment 1 is as follows:

[0034] A preparation process of durable automobile paint, the first step is to mix 80g of microgelled acrylic resin, 0.4g of HDI trimer, 0.4g of p-chloro-m-dimethylphenol, 0.2g of GPE type polyoxyethylene polyoxypropylene glycerin The ether and 0.2g of anionic polyacrylamide were mixed at the same time, fully stirred with a mixer, and stirred for 30 minutes at a stirring speed of 1000r / min until a latex was formed; in the second step, the latex was stirred for 30 minutes at a stirring speed of 1000r / min, The first vacuuming, the negative pressure value is -0.06MPA; the third step, the latex obtained in the second step is slowly heated up, the reaction temperature is kept at 60 ° C, and the reaction is stirred at a constant temperature for 2 hours, and the stirring speed is 1000r / min , the second vacuuming, the negative pressure value is -0.08MPA, then stop stirring, t...

Embodiment 8

[0045] In Example 8, a filler is added in the second step, and the filler in Example 8 is phenyl o-hydroxybenzoate.

Embodiment 9

[0046] The difference between Example 9 and Example 8 is that the filler of Example 9 is talc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com