PCB surface defect detection method based on frequency domain information double confirmation

A technology of defect detection and frequency domain, applied in image analysis, image enhancement, instruments, etc., can solve problems such as limiting PCB supply quality and imaging noise interference, and achieve improved PCB supply quality, high robustness, and fast evaluation speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

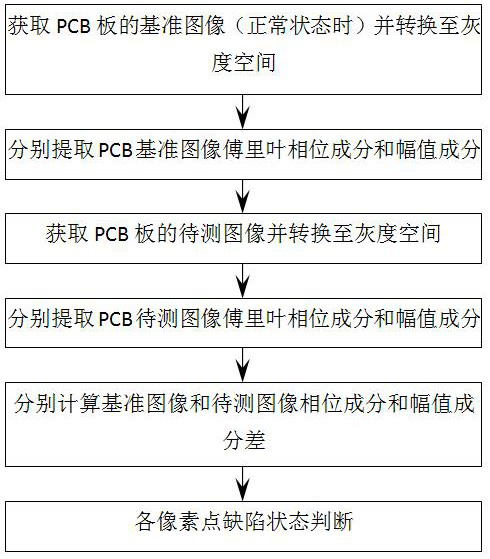

[0051] Embodiment 1: A PCB surface defect detection method based on double confirmation of frequency domain information, the flowchart of which is as follows: figure 1 As shown, establishing a PCB image acquisition device also includes the following steps:

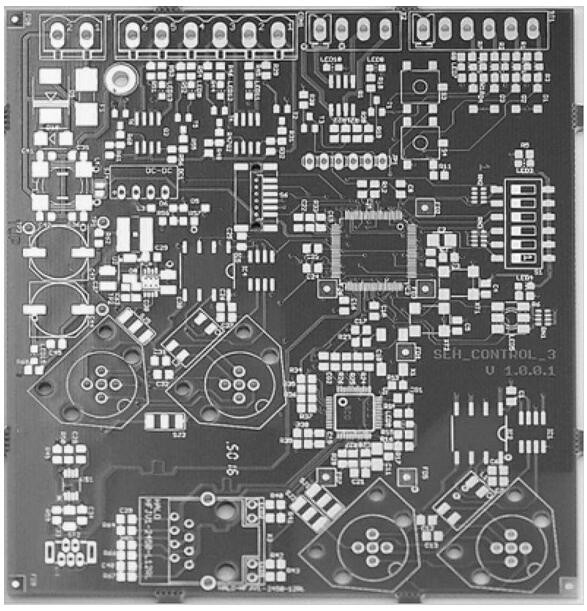

[0052] S1: Obtain the reference image of the PCB board to obtain the PCB reference image (in normal state), and convert it to gray space; figure 2 The specific conversion method is as follows:

[0053]

[0054] Among them, I is the generated grayscale image, R is the red channel of the color image, G is the green channel of the color image, and B is the blue channel of the color image

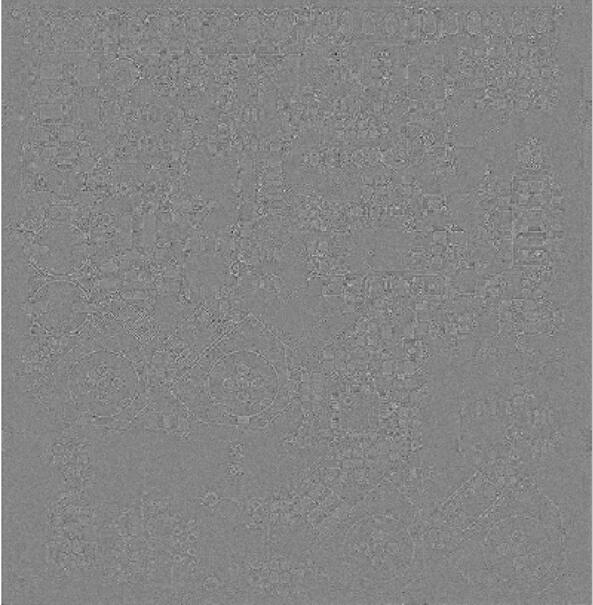

[0055] S2: Extract the Fourier phase component and amplitude component of the PCB reference image respectively; image 3 , attached Figure 4As shown, the extraction method of the Fourier phase component and the amplitude component of the image includes the following steps:

[0056] SS1: Calculate the two-dimensional Fourier transfo...

Embodiment 2

[0072] Embodiment 2: A PCB surface defect detection method based on double confirmation of frequency domain information, the flowchart of which is as follows: figure 1 As shown, establishing a PCB image acquisition device also includes the following steps:

[0073] S1: Obtain the reference image of the PCB board to obtain the PCB reference image (in normal state), and convert it to gray space; Figure 12 The specific conversion method is as follows:

[0074]

[0075] Among them, I is the generated grayscale image, R is the red channel of the color image, G is the green channel of the color image, and B is the blue channel of the color image

[0076] S2: Extract the Fourier phase component and amplitude component of the PCB reference image respectively; Figure 13 , attached Figure 14 As shown, the extraction method of the Fourier phase component and the amplitude component of the image includes the following steps:

[0077] SS1: Calculate the two-dimensional Fourier tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com